Application of silica nano material in polyester-imide enameled wire insulating varnish

A technology of enameled wire insulation and silicon dioxide, applied in the direction of coating, etc., can solve the problems of easy gelation of insulating varnish, complex process, rough surface of enameled wire, etc., and achieve the effect of stable process production and wide process margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] With 6 parts of silicon dioxide nanomaterials (particle diameter 25 nanometers), adopt the method of the present invention, disperse in 50 parts of polyesterimide paints, 50 parts of modified polyester paints, and use this as primer, polyamide imide The amine enameled wire insulation varnish is used as the top coat (such as Shanghai Shengran's 338 / 35), and it is made into a 200-grade polyamide-imide composite polyesterimide frequency conversion enameled wire.

[0022] The method for dispersing silica nanomaterials in polyesterimide paint is as follows:

[0023] (1) Pre-disperse 6 parts of nano-silica and 0.6 parts of γ-aminopropyltriethoxysilane (KH550) in 40 parts of modified polyester paint, and feed the silica in 9 times In dispersion A, each interval is 30 minutes to generate pre-dispersion A;

[0024] (2) Add 50 parts of polyesterimide enameled wire insulating varnish and 10 parts of modified polyester varnish to pre-dispersion A, and disperse for 1 hour to form p...

Embodiment 2

[0027] With 8 parts of silicon dioxide nanomaterials (particle diameter 25 nanometers), adopt embodiment 1 method, disperse in 50 parts of polyesterimide paints, in 50 parts of modified polyester paints, and use this as primer, polyamide amide The insulating varnish of imide enameled wire is the top coat (such as Shanghai Shengran's 338 / 35), which is made into 200-grade polyamide-imide composite polyesterimide frequency conversion enameled wire.

[0028] Preparation of enameled wire sample wire

[0029] Coating process parameters are as follows:

[0030] Coating equipment: Meda QHLF1 / 2

[0031] Process parameters:

[0032] Oven inlet: 230°C; Lower layer of oven: 350°C; Supplementary heating after catalysis: 520°C; Circulation fan: 2100RPM; Exhaust fan: 800RPM; Cooling fan: 400RPM

[0033] Speed: 30 m / min

[0034] Painting passes: 9+3

[0035] The enameled wire specification is 1.05

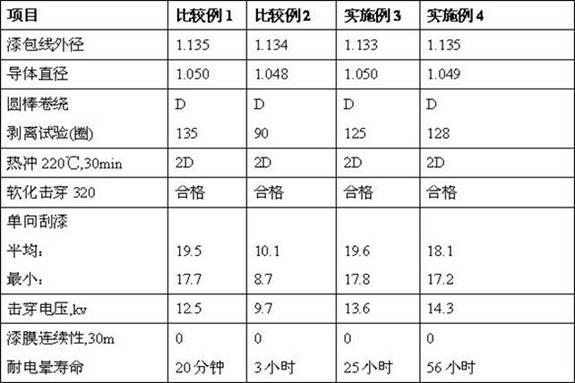

[0036]

[0037] The test method of corona resistance life is: rise time 200 nanosecon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com