Method for synthesizing alpha-aminophosphonate through water phase cleaning

An amino phosphonate and clean technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problems of catalysts that do not have large-scale industrial applications, catalysts that cannot be recycled, and catalyst preparation Complex process and other issues, to achieve the effect of large-scale industrial production, stable to water, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

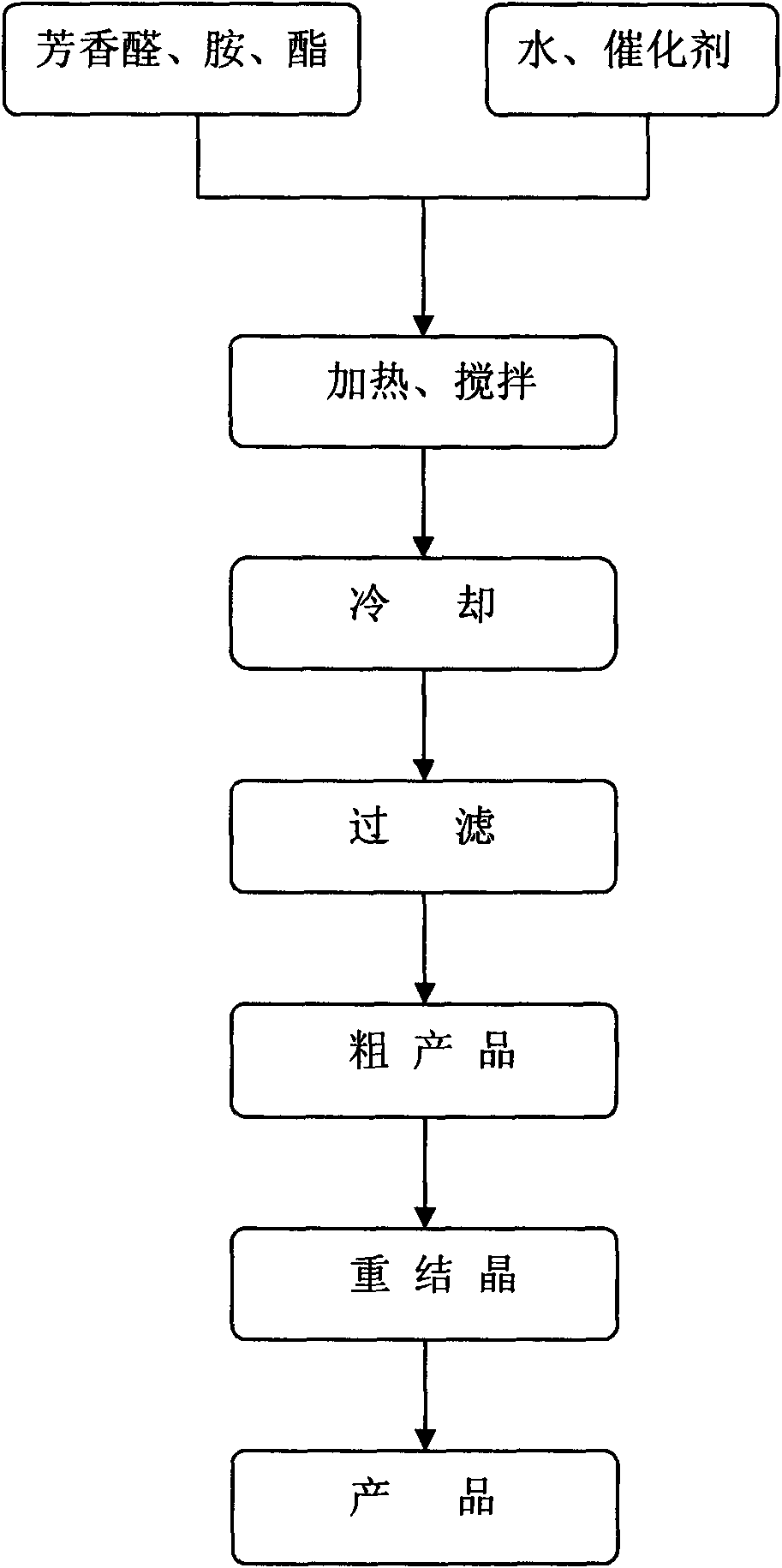

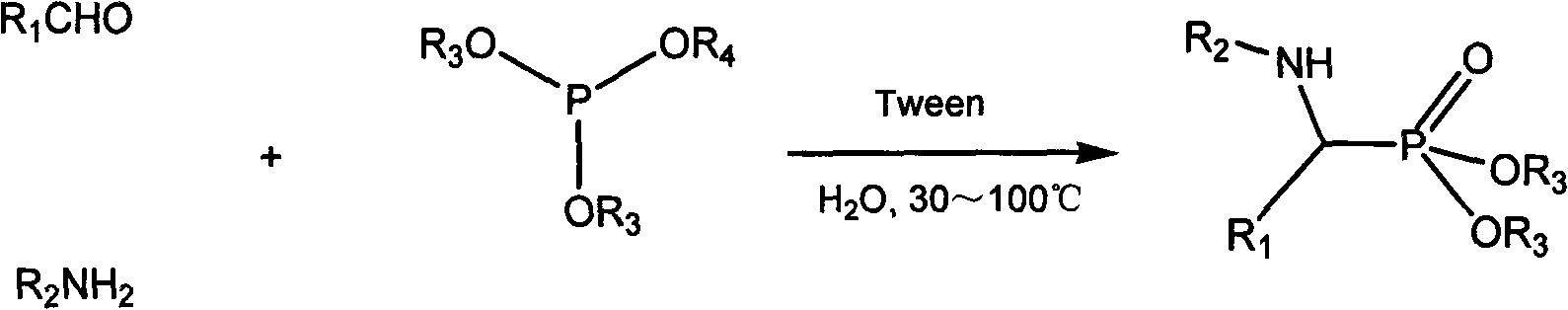

Method used

Image

Examples

Embodiment 1

[0021] In a 25mL round bottom flask, add 10mmol (1.06g) of benzaldehyde, 10mmol (0.93g) of aniline, 11mmol (1.83g) of triethyl phosphite, 1mmol of Tween-20 and 15ml of water in sequence, and mix at 60°C under normal pressure Stir for 30 minutes, filter and wash with cold water, and recrystallize from ethanol to obtain pure diethyl α-anilino-benzylphosphonate with a yield of 91%.

Embodiment 2

[0023] In a 25mL round bottom flask, add 10mmol (1.36g) p-methoxybenzaldehyde, 10mmol (1.38g) 4-nitroaniline, 12mmol (1.32g) trimethyl phosphite, 0.5mmol Tween-20, 5mL of water, mixed and stirred at 70°C for 60 minutes, filtered and washed with cold water, recrystallized from methanol to obtain pure dimethyl α-(4-nitroanilino)-(4-methoxyphenyl)methylphosphonate Product, yield 86%.

Embodiment 3

[0025] In a 25mL round bottom flask, add 10mmol (1.06g) benzaldehyde, 10mmol (0.93g) aniline, 20mmol (2.76g) diethyl phosphite, 0.1mmol Tween-20, 0.1mmol Tween-60 and 1.5ml water in sequence , mixed and stirred at 60° C. under normal pressure for 45 minutes, filtered and washed with cold water, and recrystallized from ethanol to obtain pure diethyl α-anilino-benzylphosphonate with a yield of 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com