Method for producing low-salt high-quality sodium carbonate by combined filtration

A high-quality, soda ash technology, applied in the field of processing, can solve the problems of difficulty in large-scale, large washing water equivalent, affecting soda ash production, etc., and achieves the reduction of construction investment and operation costs, reduction of filtration area and power consumption, and improvement of raw material utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

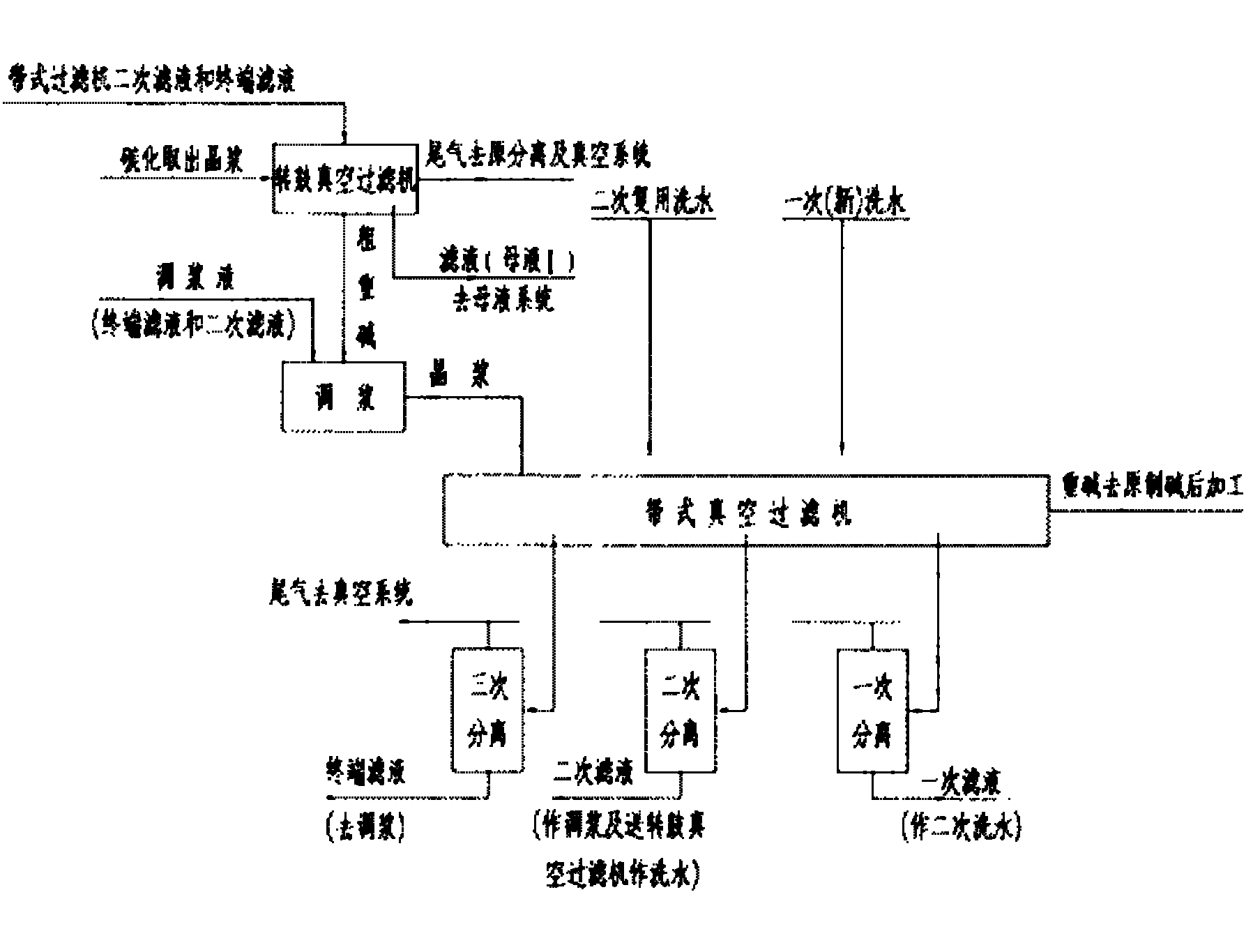

Image

Examples

Embodiment 1

[0030] The production method of a certain soda plant is combined soda production method, and the production scale is about 200,000 tons of soda ash per year.

[0031] The soda-making carbonization tower takes out the crystalline slurry (containing about 20-30% of the solid content depending on the volume ratio) and presses it into the lye tank of the drum vacuum filter, and then filters and washes for the first time through the drum vacuum filter (drum hollow , both ends are equipped with hollow shafts connected with vacuum pipes), under the suction of the vacuum pump, the solid-heavy alkali in the crystal slurry is intercepted on the filter medium (stainless steel metal mesh, etc.), forming a thick heavy alkali filter cake, air and The liquid is pumped away through the hollow shaft, and enters the gas-liquid separation and purification system to recover the mother liquor, etc. The heavy alkali filter cake is washed with washing water (the secondary filtrate and terminal filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com