Supporting device for battery pack of electric automobile

A technology for electric vehicles and battery packs, used in electric power units, power units, vehicle components, etc., can solve problems such as electrolyte leakage, wire wear, battery wiring disconnection, etc., to reduce shock and vibration, improve service life, improve The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

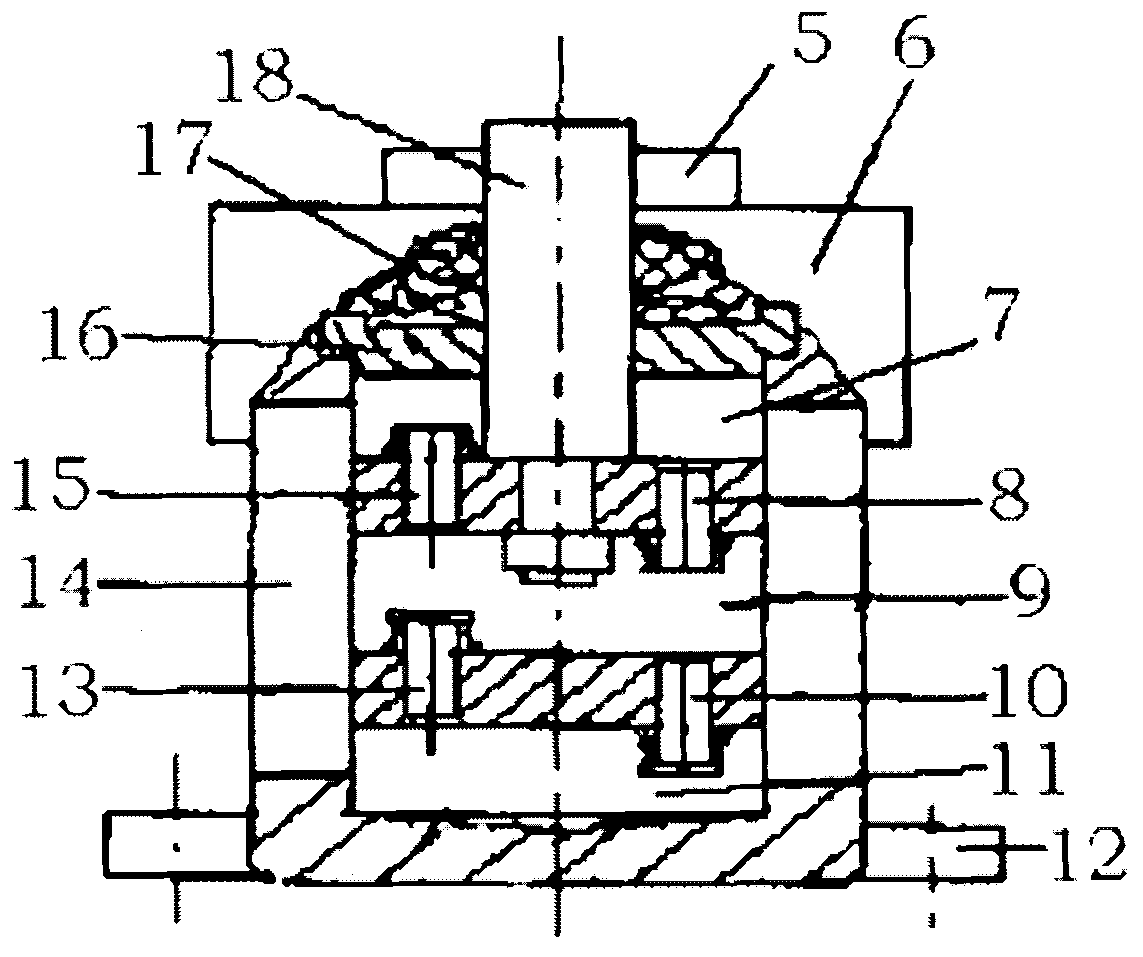

[0013] The invention provides a supporting device for a battery pack of an electric vehicle. Further description will be given below in conjunction with the accompanying drawings.

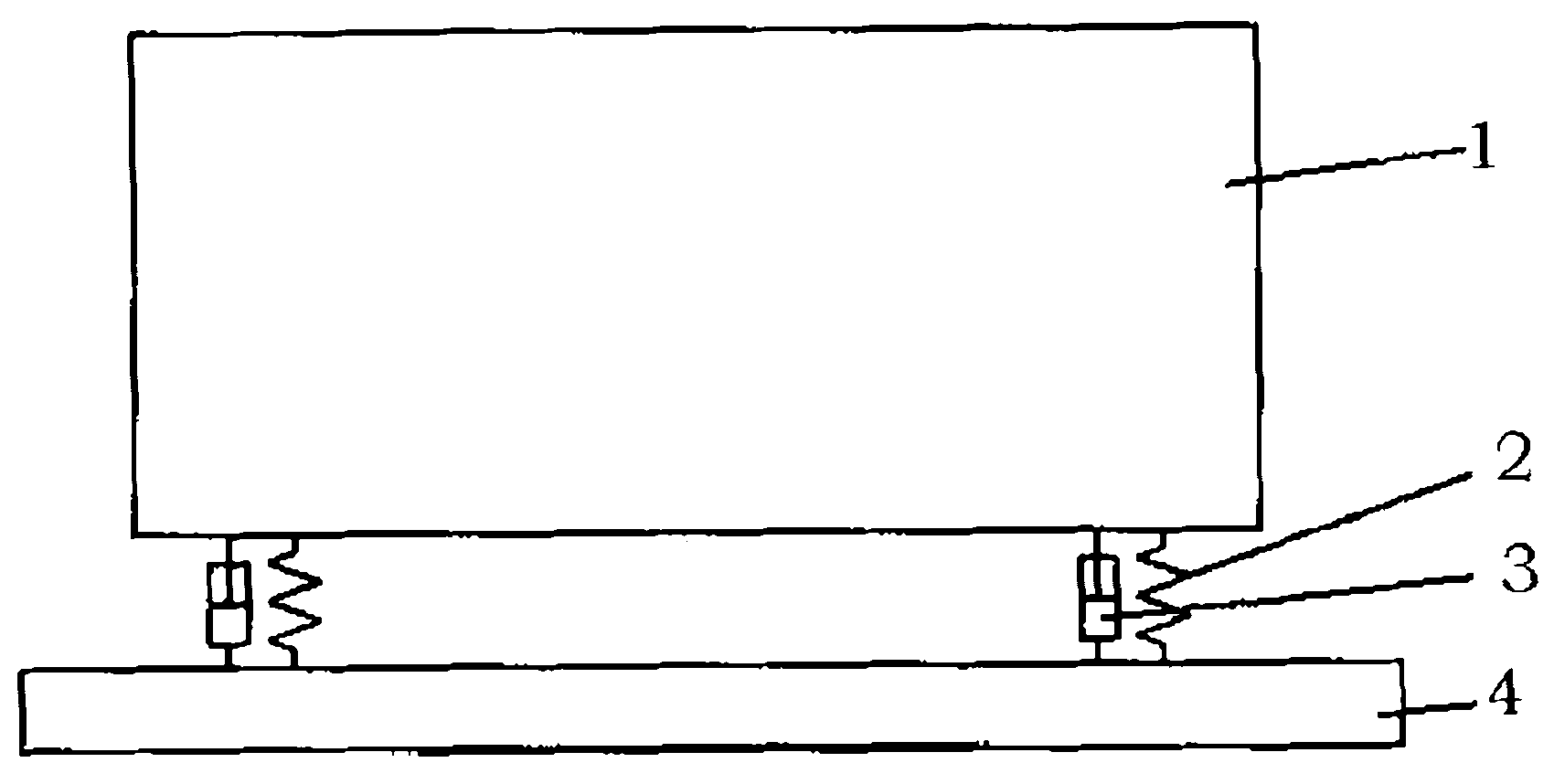

[0014] figure 1 Shown is a schematic diagram of the structure of the supporting device. In the figure, the battery pack 1 is connected to the vehicle frame 4 through four sets of parallel springs 2 and dampers 3 to reduce the shock and vibration transmitted to the battery pack 1 during the operation of the vehicle, thereby improving The stressed condition of the battery pack 1 improves the service life. The spring stiffness of spring 2 can be calculated and selected according to the following formula:

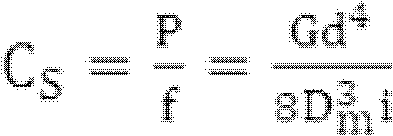

[0015] C S = P f = Gd 4 8 D m 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com