Method for manufacturing stainless steel seamless tube

A manufacturing method and seamless pipe technology, applied in the field of manufacturing, can solve problems such as production technology, equipment level operation technology, product quality gap, inability to produce hot-rolled finished pipes, and poor capillary dimensional accuracy, so as to shorten the production cycle and reduce Good effect of cold working amount and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

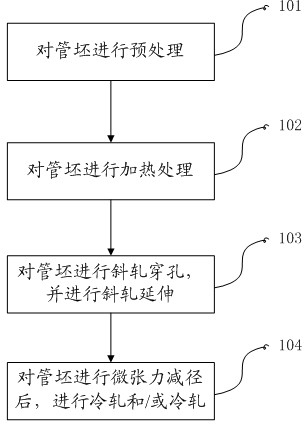

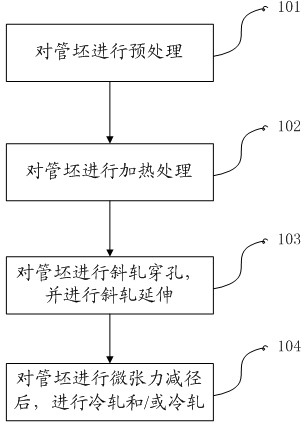

[0045] The first embodiment of the present invention proposes a method for manufacturing stainless steel seamless pipes, the process of which is as follows figure 1 shown, including:

[0046] Step 101, pretreating the tube blank;

[0047] Step 102, heat-treating the tube blank;

[0048] Step 103, cross-rolling and piercing the tube blank, and cross-rolling and extending;

[0049] Step 104, performing cold rolling and / or cold rolling on the tube blank after micro-tension reduction.

[0050]

no. 2 example

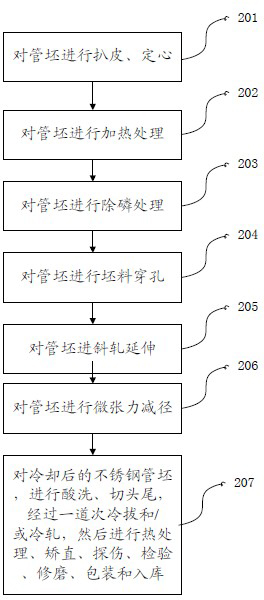

[0052] The second embodiment of the present invention proposes a stainless steel seamless pipe manufacturing method for manufacturing No. 304 seamless steel pipe with a diameter of 108 mm and a length of 8 meters; a pipe blank with a diameter of 120 mm and a length of 1500 mm is used. The flow process of the stainless steel seamless pipe manufacturing method of the second embodiment of the present invention is as follows figure 2 shown, including:

[0053] Step 201, skinning and centering the tube blank. Wherein, peeling is to remove the skin of the tube blank, and the thickness of the removed skin is 0.6mm. Centering is to open a hole with a diameter of 30mm and a depth of 10mm at the center of the tube blank to determine the center of the tube blank. Then you can further inspect, grind and clean the tube blank. The inspection can be carried out with the naked eye to confirm that there are cracks, scars and other defects on the surface of the round billet. Grinding can u...

no. 3 example

[0061] The third embodiment of the present invention proposes a stainless steel seamless pipe manufacturing method, which is used to manufacture No. 316 seamless steel pipe with a diameter of 178 mm and a length of 10 meters; a pipe blank with a diameter of 175 mm and a length of 2000 mm is used. The flow process of the stainless steel seamless pipe manufacturing method of the third embodiment of the present invention includes:

[0062] Step 301, skinning and centering the tube blank. Wherein, peeling is to remove the skin of the tube blank, and the thickness of the removed skin is 0.8mm. Centering is to open a hole with a diameter of 40mm and a depth of 15mm at the center of the tube blank to determine the center of the tube blank. Then you can further inspect, grind and clean the tube blank. The inspection can be carried out with the naked eye to confirm that there are cracks, scars and other defects on the surface of the round billet. Grinding can use a grinder to grind ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com