Application of Cu-Fe-based catalyst in synthesis of higher alcohol with synthetic gas

A catalyst and synthesis gas technology, which is used in the preparation of hydroxyl compounds, the preparation of organic compounds, catalysts for physical/chemical processes, etc., to achieve the effects of stable performance, improved selectivity, and low requirements for reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] By expression Cu 30 Fe 20 co 5 Se 2 / (SiO 2 ) 43 , wherein: x=30, y=20, z=5+2=7, y / x=0.667, z / x=0.23, prepare the catalyst, get 10.0g 30~100 mesh microsphere silica gel, according to the ratio of the above expression Prepare Cu, Fe, Co, Se nitrate aqueous solution (impregnated with equal volume), soak at room temperature for 4 hours, and then dry at 200°C. Then the temperature was raised to 400°C at a rate of 1.0°C / min and fired for 8 hours, and then cooled to room temperature naturally.

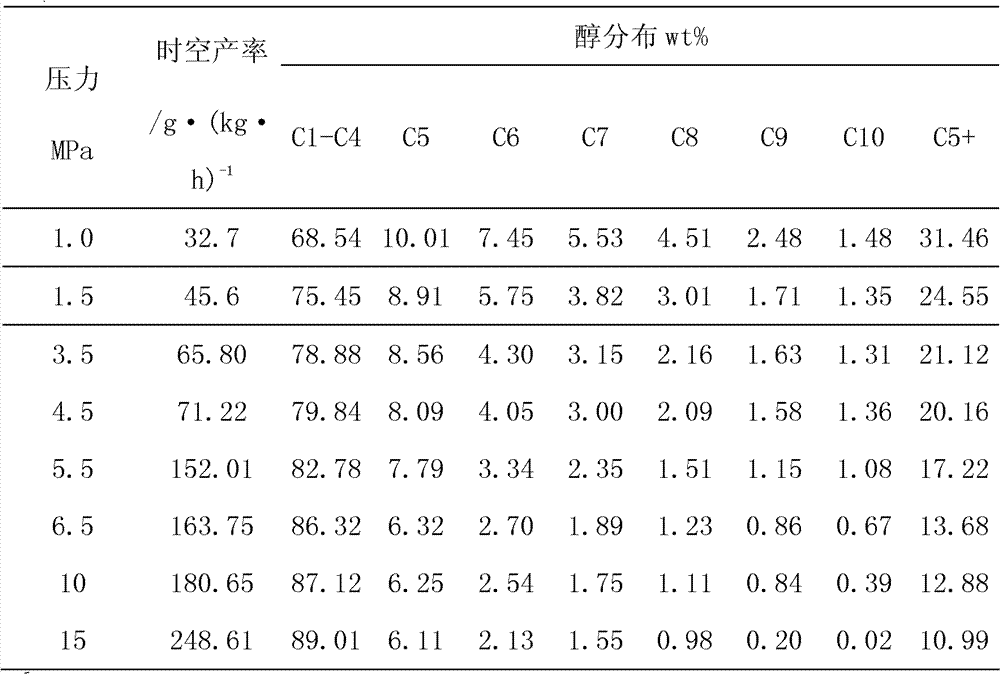

[0023] The prepared catalyst was moved into the reactor, and H 2 Reduce at 400°C for 8 hours, then switch to syngas at a pressure of 1.0-15.0MPa, a temperature of 350°C, and a space velocity of 6000h -1 , H 2 / CO=2, the liquid phase product was collected in an ice-water bath, and the product composition was analyzed by gas chromatography. The obtained results are shown in Table 1:

[0024] Table 1

[0025]

Embodiment 2

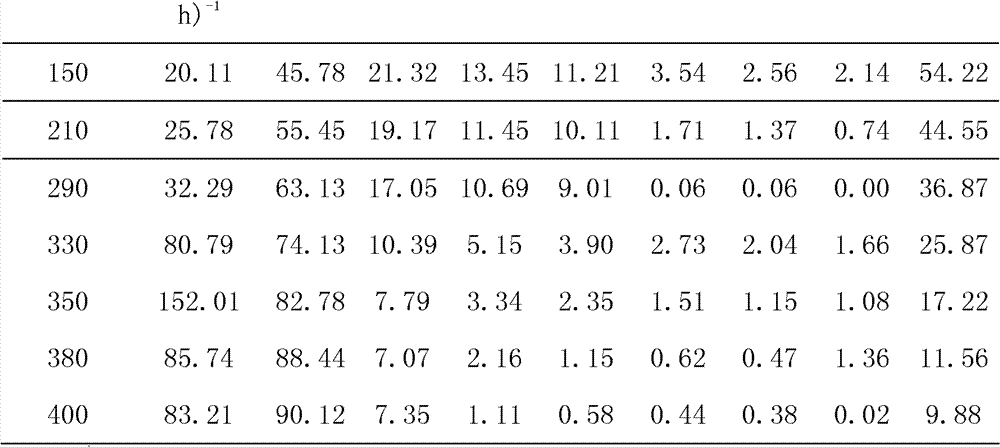

[0027] By expression Cu 25 Fe 25 Zn 1 K 2 / (Al 2 o 3 ) 43 , wherein: x=25, y=25, z=3, y / x=1, z / x=0.12, prepare catalyst, get 10.0g Al 2 o 3 , configure the oxalate of Cu, Fe, Zn, K in the aqueous solution (with equal volume impregnation) containing ethanol 5% by above-mentioned expression ratio, all the other are with embodiment 1. Pressure 5.5MPa, temperature 150-400℃, space velocity 4000h -1 , H 2 / CO=2, the obtained results are shown in Table 2:

[0028] Table 2

[0029]

[0030]

Embodiment 3

[0032] By expression Cu 20 Fe 40 Cr 2 / (SiO 2 ) 38 , where x=20, y=40, z=2, y / x=2, z / x=0.10 to prepare the catalyst, take 10.0g of 30-100 mesh microsphere silica gel, configure Cu, Fe, Cr according to the ratio of the above expression Acetate contains 30% acetone aqueous solution (with equal volume impregnation), and all the other are with embodiment 1. Pressure 5.5MPa, temperature 320℃, space velocity 500~14000h -1 , H 2 / CO=2, the obtained results are as follows:

[0033] table 3

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com