Cover opening and closing safety device of pressure cooker

A safety device, a technology for opening and closing lids, applied in pressure cookers, cooking utensils, household appliances, etc., can solve the problems of unclean pressure removal in the pot, complex structure, inconvenient use, etc., and achieve shortened cooking time, high sensitivity, and reduced The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

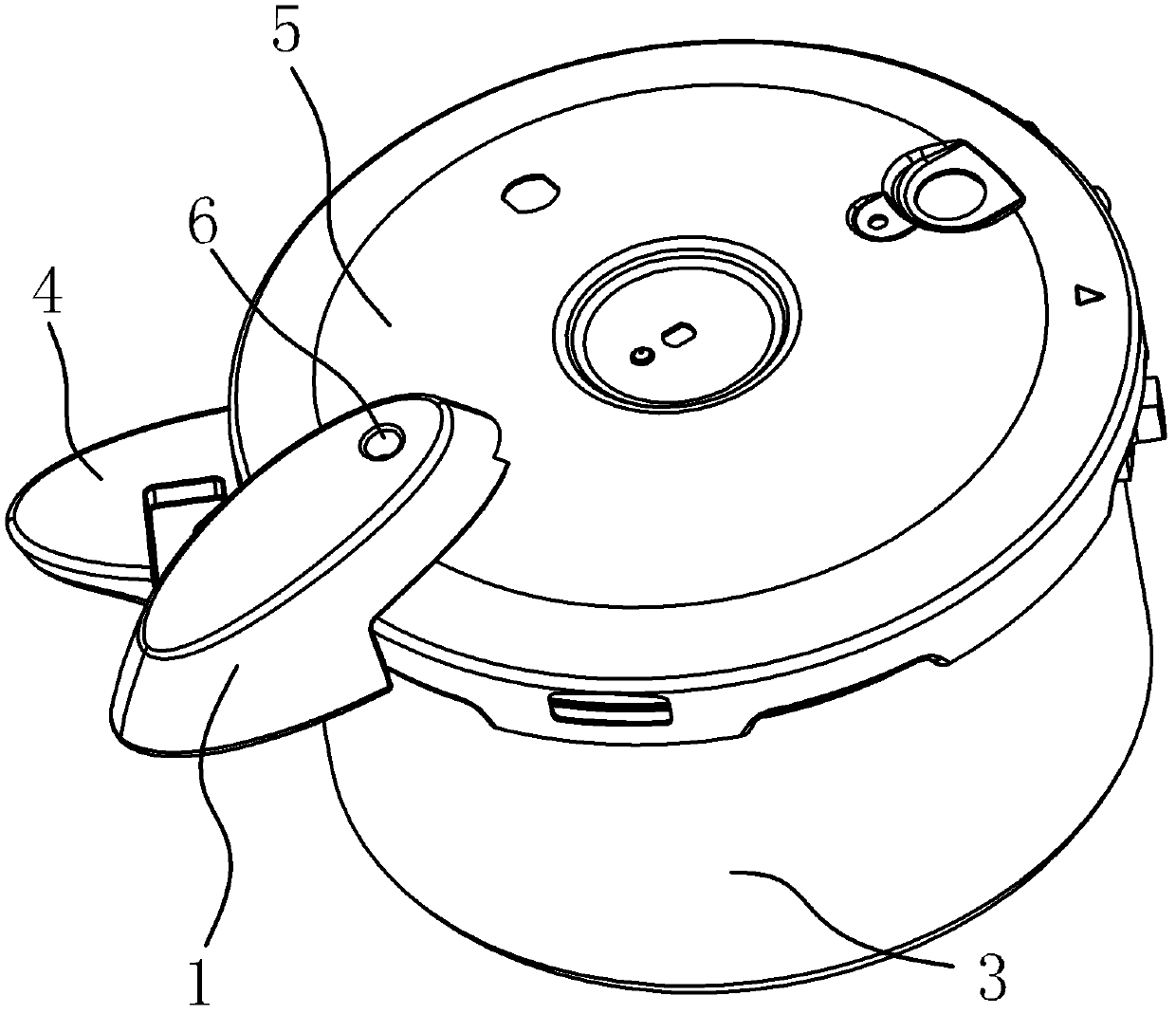

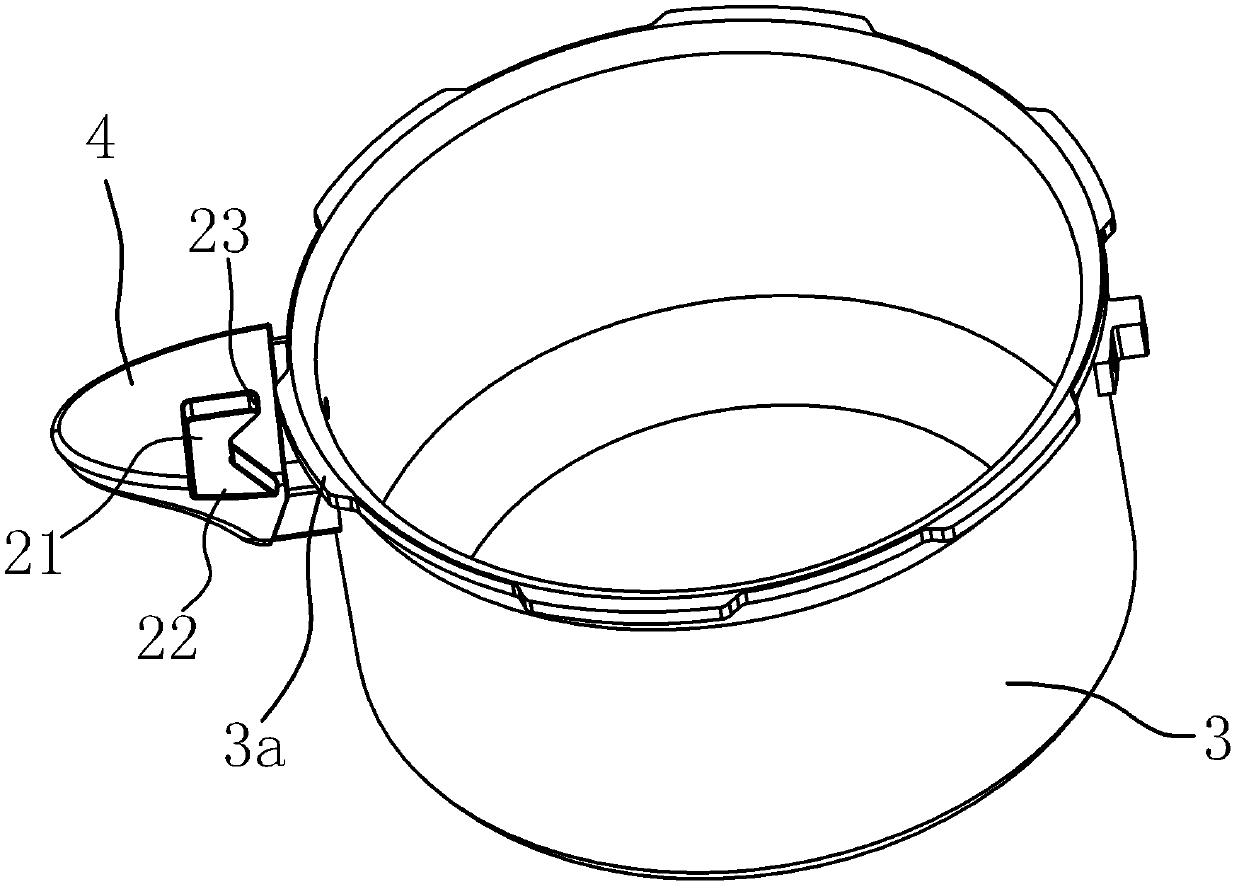

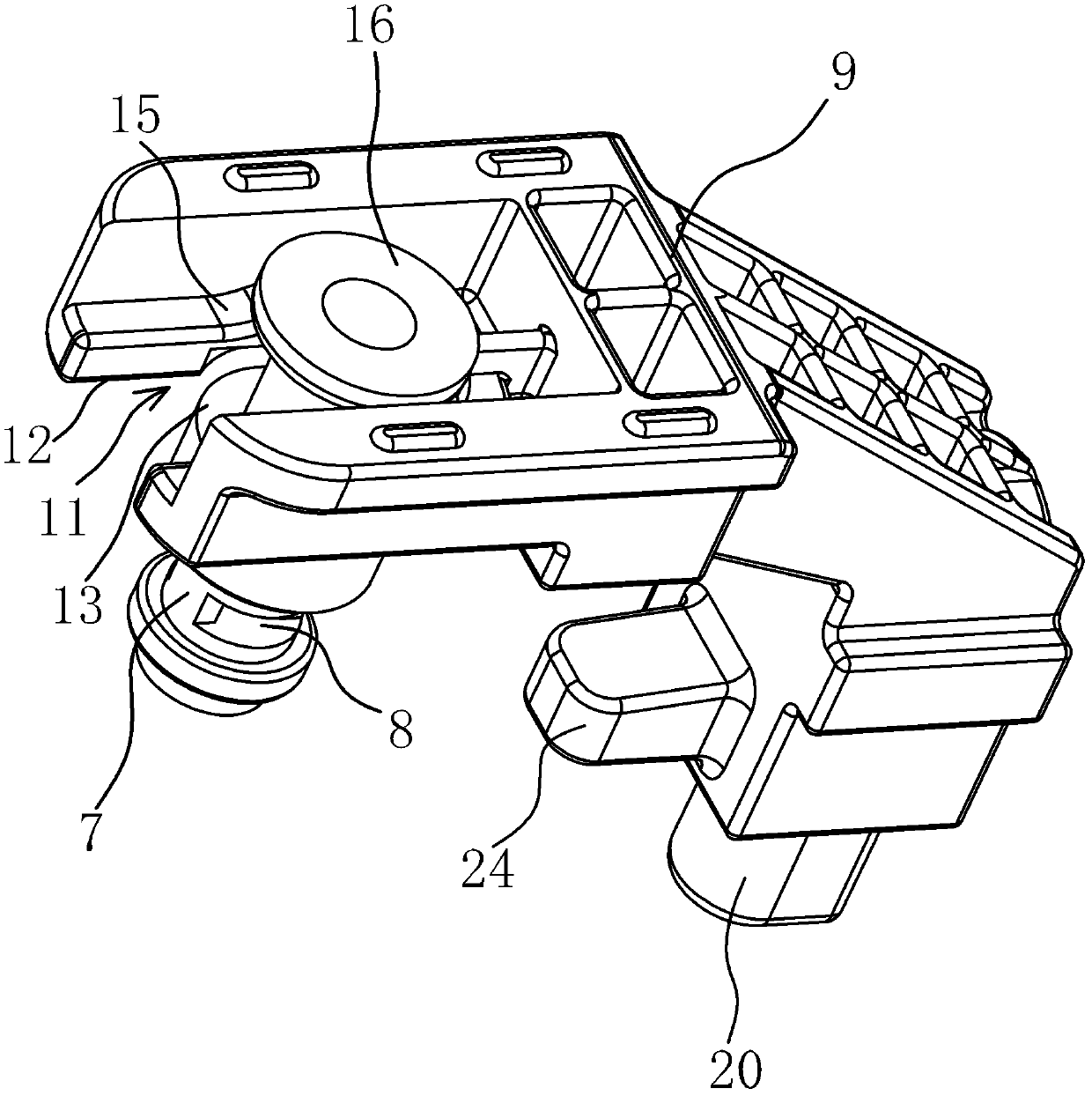

[0036] Such as figure 1 , figure 2 with Image 6 As shown, the safety device for opening and closing the lid of the pressure cooker includes an upper handle 1, a valve seat 2 and a lower handle 4 fixed on the pot body 3. The pot mouth of the pot body 3 has an outwardly turned edge 3a, and the upper handle 1 It is fixed on the pot cover 5 and the upper handle 1 has a through hole 6 communicating with the outside world. The valve seat 2 is fixed on the pot cover 5 and the valve seat 2 is pierced with a non-opening valve stem 7 that can be raised and lowered. The inner end located at the inside of the pot cover 5 is provided with an exhaust hole 8 communicating with the through hole 6, and the upper handle 1 is provided with a push plate 9 that can slide close to or away from the edge of the pot cover 5, and the push plate 9 and the upper handle 1 A spring 10 with one end against the upper handle 1 and the other end against the push plate 9 is arranged between them. In order ...

Embodiment 2

[0043] Such as Figure 9 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference lies in that the lifting structure in this embodiment includes a top block 17 on the upper part of the bayonet 11 and a peripheral edge at the outer end of the valve stem 7. To the raised lifting block 18 , the contact surface of the lifting block 18 and the top block 17 is a slope 19 , and the slope 19 is inclined downward from the inside of the bayonet 11 toward the end. When the push plate 9 approaches the pot body 3 under the elastic force of the spring 10, the top block 17 touches the slope 19 of the lifting block 18, so that the lifting block 18 drives the stop valve stem 7 to rise together until the stop valve stem The exhaust hole 8 of 7 is located on the sealing surface of the valve seat 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com