Functional material liquid for improving cigarette quality and preparation and application thereof

A functional, material-liquid technology, applied in the application, preparation of tobacco, tobacco and other directions, can solve the problems of incomplete effect, incomplete effect, single type of enzyme, etc., to improve the quality of cigarettes, easy to operate, and improve internal components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

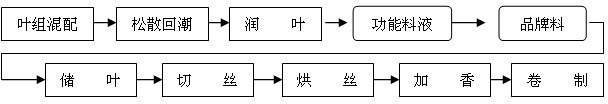

Method used

Image

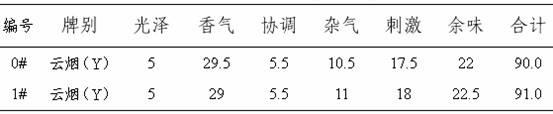

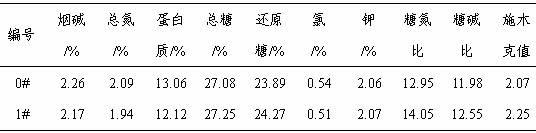

Examples

Embodiment 1

[0030] The activated Bacillus subtilis was inserted into the sterilized expansion medium, and cultured with shaking at 30° C. for 24 hours, as the seed solution. Finally, the seed solution was added to the fermentation medium at a ratio of 5%, and cultured with shaking at 30°C for 24 hours, and the resulting bacterial solution was filtered to obtain the Bacillus subtilis fermentation solution; the activated aroma-producing yeast was inserted into the sterilized Bacteria expansion medium, at 30 ° C, shaking culture for 24 hours, as the seed solution. Afterwards, the seed liquid was inserted into the fermentation medium at a ratio of 10%, and cultured with shaking at 30°C for 24 hours, and the resulting bacterial liquid was filtered to obtain the aroma-producing yeast fermentation liquid; the lignin-degrading compound enzyme (lignin peroxidase ( LiP), manganese peroxidase (MnP) and laccase (Lac)), cellulase and pectinase are commercial enzymes. Among them, the fermentation liqu...

Embodiment 2

[0042] Repeat Example 1, with the following differences: 50% of the Bacillus subtilis fermentation broth, 25% of the aroma yeast fermentation broth, 25% of the cell wall degrading enzyme system (wherein 10% of the lignin degrading compound enzyme, 10% of the cellulase, fruit Gelase 5%) was compounded to prepare functional material liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com