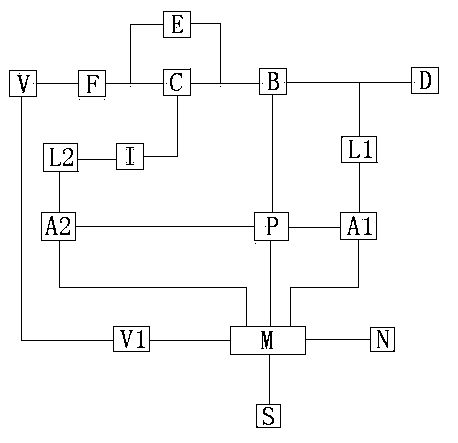

Double-closed-loop feedback-control module

A feedback control and closed-loop control technology, applied in relays, electrical components, circuits, etc., can solve problems such as the increase in the cost of switch protection and control loops, the current impact of the switch tube in the starting circuit, and the difficulty in implementing voltage control schemes. The effect of increased cost, improved reliability, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention applies the current type PWM control system adopted in the switching power supply to the intelligent control of the AC contactor. When the system is powered on, the level state of the circuit is set by the microcontroller detection mode, and according to different level states, it enters the parameter setting program or loads the last set parameters to run directly. If it is in the parameter setting state, through the parameter setting and display circuit, you can set the starting current time domain curve of the AC contactor, keep the current value, and store and display the setting parameters.

[0028] If it is in the running state, the system AC voltage sampling sub-circuit samples the AC voltage cyclically. If the voltage value is within the set pull-in threshold, the microcontroller starts the PWM control system and drives the power electronic switch to cut the loop of the AC contactor coil. Wave control, the contactor enters the starting phase, the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com