New-type noise-reducing sponge for excavating-machine cab

A driver's cab and excavator technology, applied in the field of new noise reduction sponge, can solve the problems of poor noise reduction effect, affecting operator comfort and labor efficiency, low sound absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

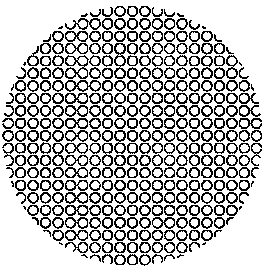

[0007] Attached below figure 1 , attached figure 2 and attached image 3 The present invention is further described: high-density sound-absorbing materials are selected, sound-absorbing and noise-reducing holes with an interval of 8 mm are densely arranged in the sponge, and the inner surface of the sound-absorbing and noise-reducing holes falls from top to ” shape, and there are evenly distributed annular grooves on the inner surface wall. This can improve the sound field distribution during the sound absorption inside the noise reduction hole of the sponge, so that the sound absorption rate of the sponge can be increased to 70%--80%.

[0008] The high-density sound-absorbing material here means at least 50 density or more, more preferably 80 density or more. The high-density sound-absorbing material has a relatively hard texture, which facilitates the processing of the internal structure of the noise reduction hole. High-density sound-absorbing materials are available i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com