Circular rubber-covered-wire optical cable and manufacturing method thereof

A technology of a sheathed optical cable and a manufacturing method, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of poor bending performance, unable to fully exert the performance of G657 optical fiber, etc., and achieve the effects of good bending performance, simple and reliable manufacturing process, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

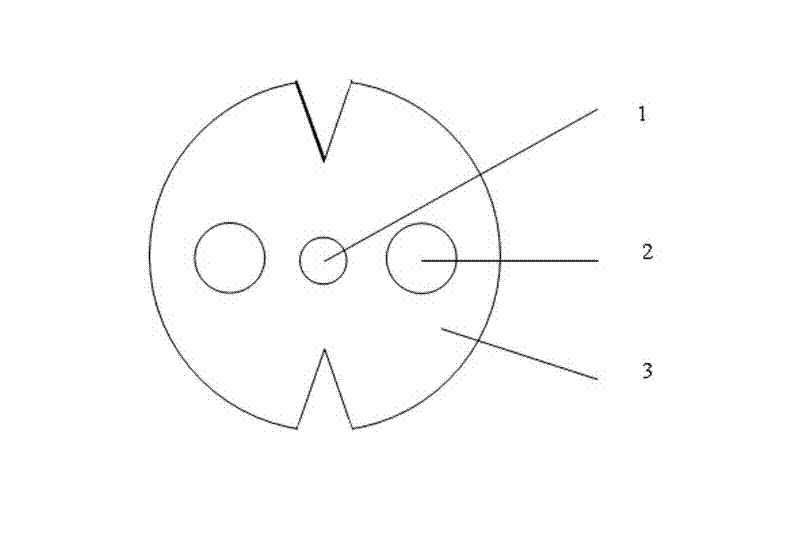

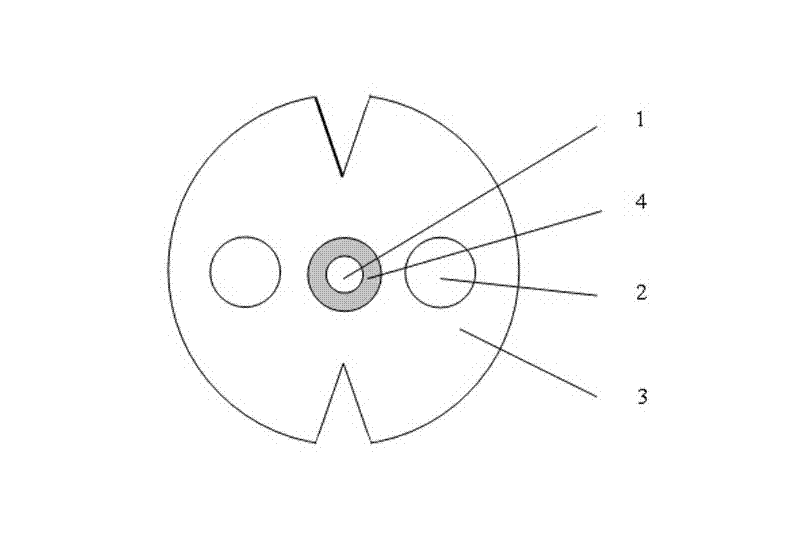

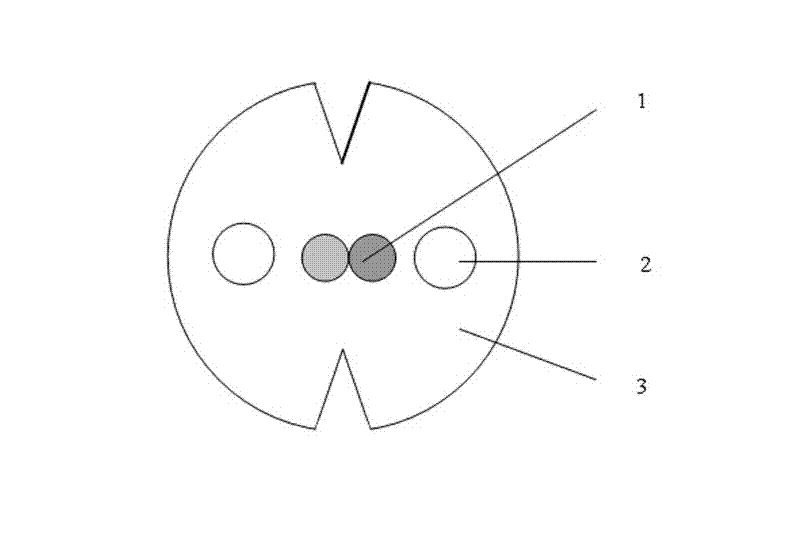

[0039] Refer to attached Figure 1~3 , the circular covered cable structure includes an optical fiber unit 1, a strengthening member 2 and a slotted sheath 3, the optical fiber unit 1 is arranged in the middle of the circular covered cable, and both sides of the optical fiber unit 1 are provided with reinforcing members 2 parallel to each other. The outside of the unit 1 and the reinforcement 2 is covered with a slotted sheath 3 .

[0040] The slotted sheath 3 is made of materials such as polyvinyl chloride or low-smoke halogen-free flame-retardant polyolefin. The optical fiber unit 1 is a colored optical fiber unit or a tight-packed optical fiber unit, and the strengthening member is a metal strengthening member or a non-metallic strengthening member (core).

[0041] At least one optical fiber unit or tight-packed optical fiber unit is used. The optical fiber unit adopts G657A2 colored optical fiber, which is usually blue, with two cores in blue and orange, and four cores i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com