Baking microwave oven and control method thereof

A control method and technology of microwave ovens, applied in the field of microwave ovens, can solve problems such as lack of pertinence, inability to ensure the uniformity of heating of grilled objects, and overheating, so as to achieve the effect of improving the grilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make those skilled in the art better understand the solution of the present invention, the present invention is further described in detail below with reference to the accompanying drawings and embodiments.

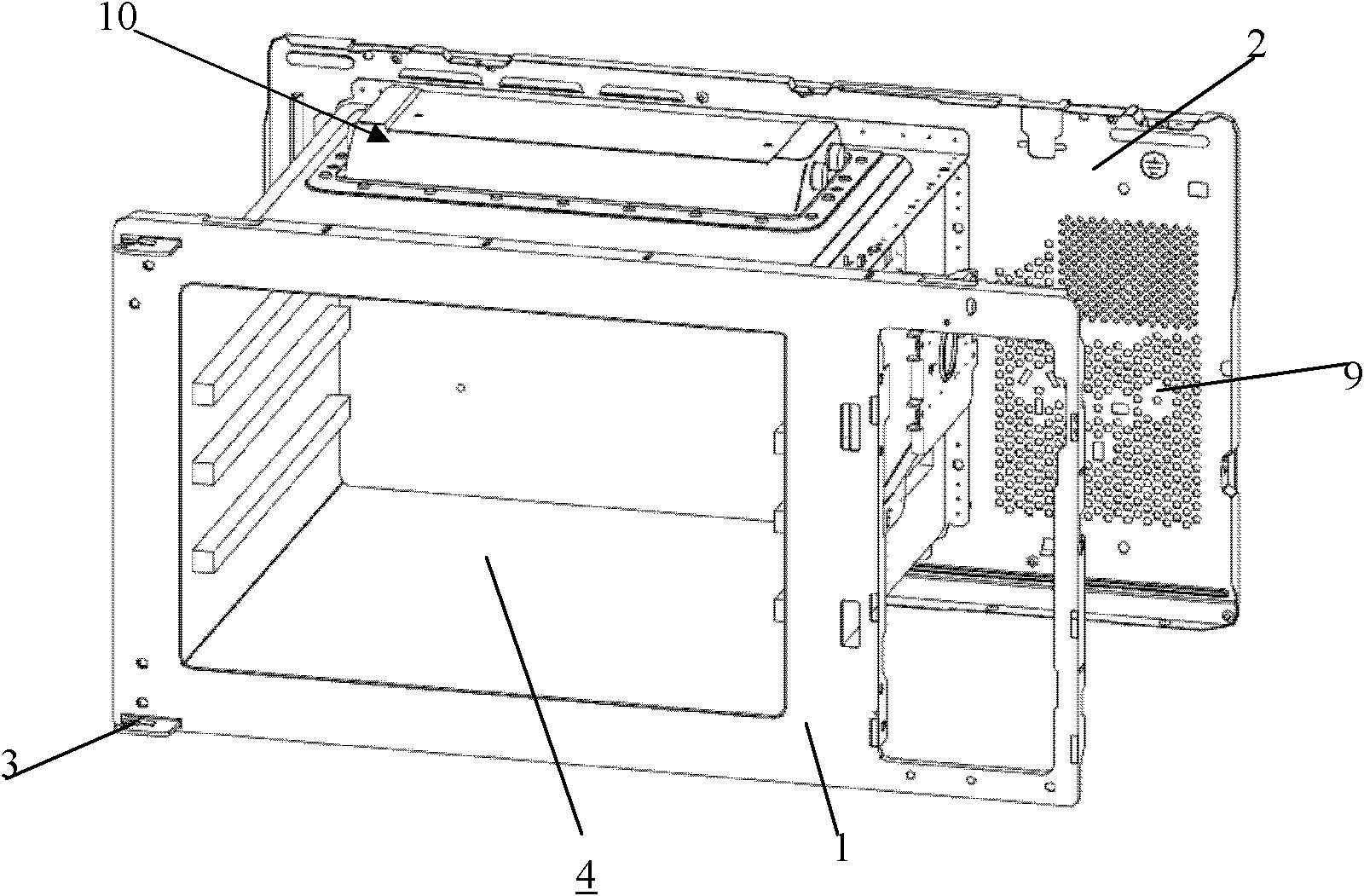

[0035] like Figure 4-7 As shown, the hexahedral rectangular box of the microwave oven is formed by a heating chamber enclosed by a front panel, a rear panel, a side panel, a top panel, a bottom panel, and a furnace door whose hinge shaft is connected in front of the front panel. A microwave generator is arranged in the electric storage chamber on one side of the microwave oven, and the microwaves generated by the microwave generator are emitted upward from the bottom surface of the heating chamber. The front panel in front of the electric storage room is formed with control panel mounting holes for installing the control panel; the rear panel at the rear of the electric storage room is formed with heat dissipation holes.

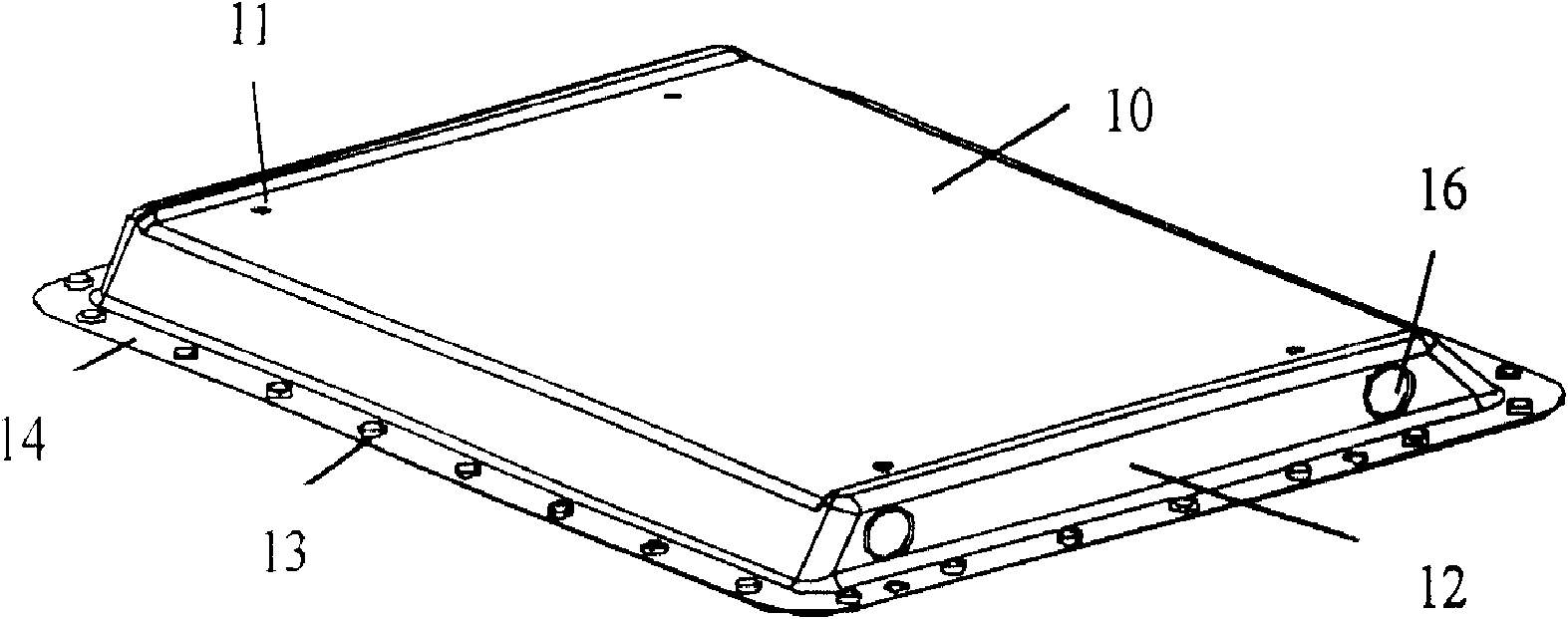

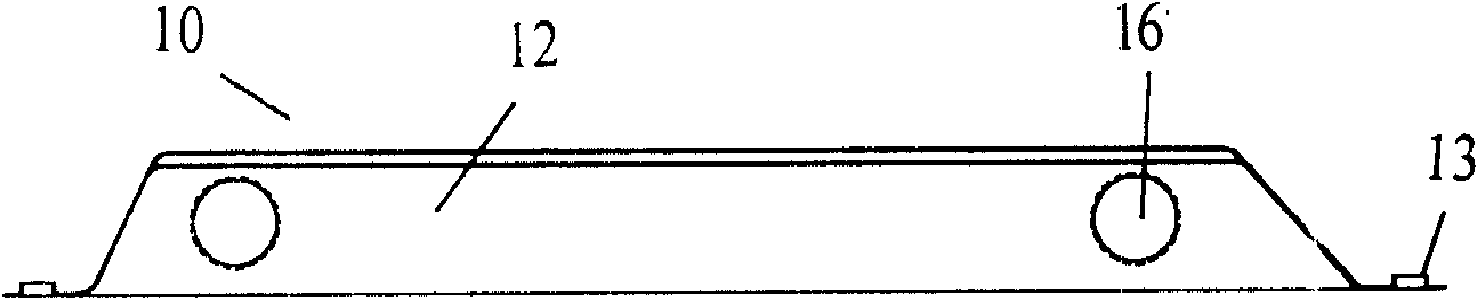

[0036] A grill tube reflecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com