Prefabricated board unit for net rib board

A technology of prefabricated slabs and ribs, applied to floors, building materials, building components, etc., can solve the problems of top box and bottom box, such as heavy weight, low safety performance, and weak earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0155] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

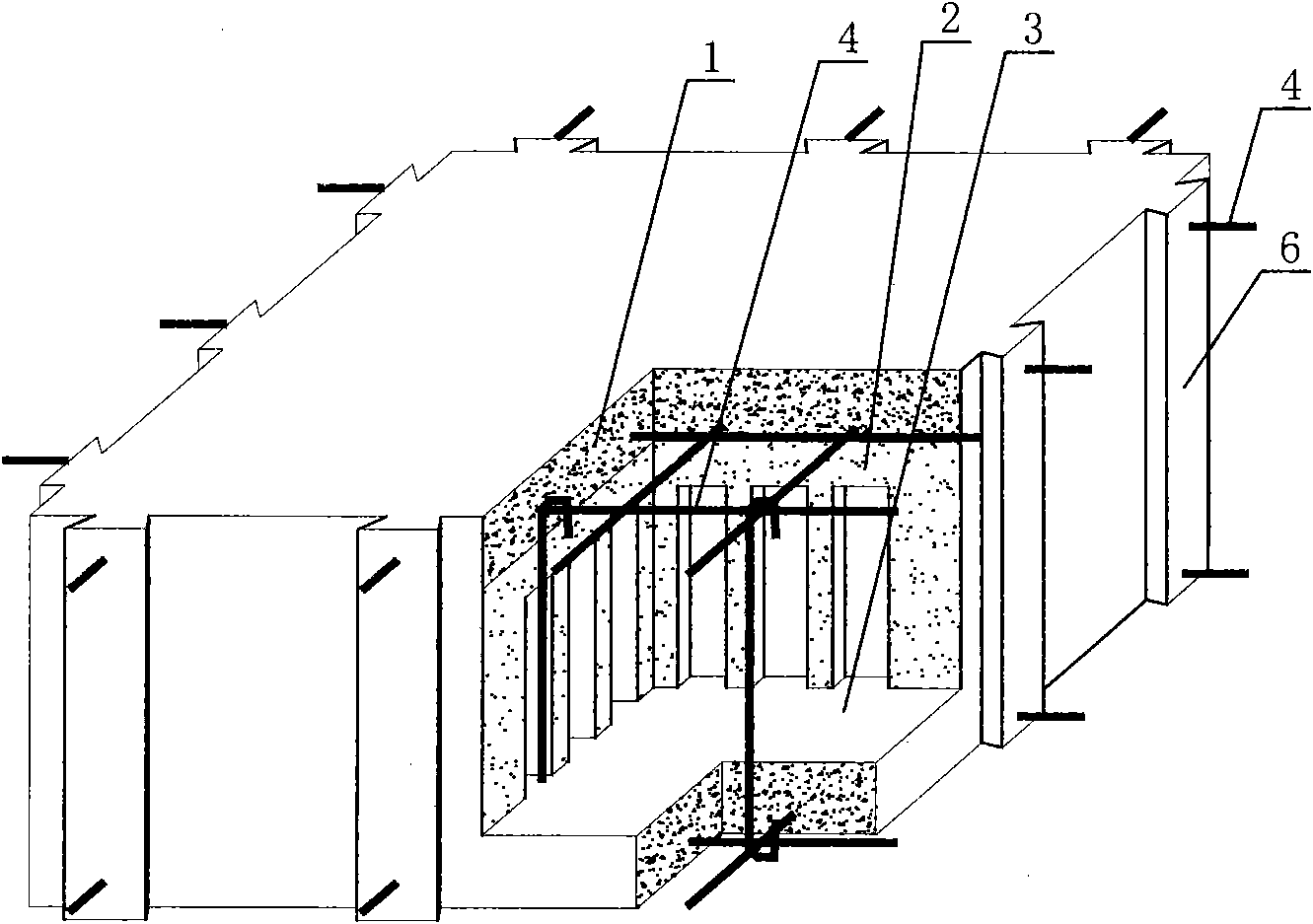

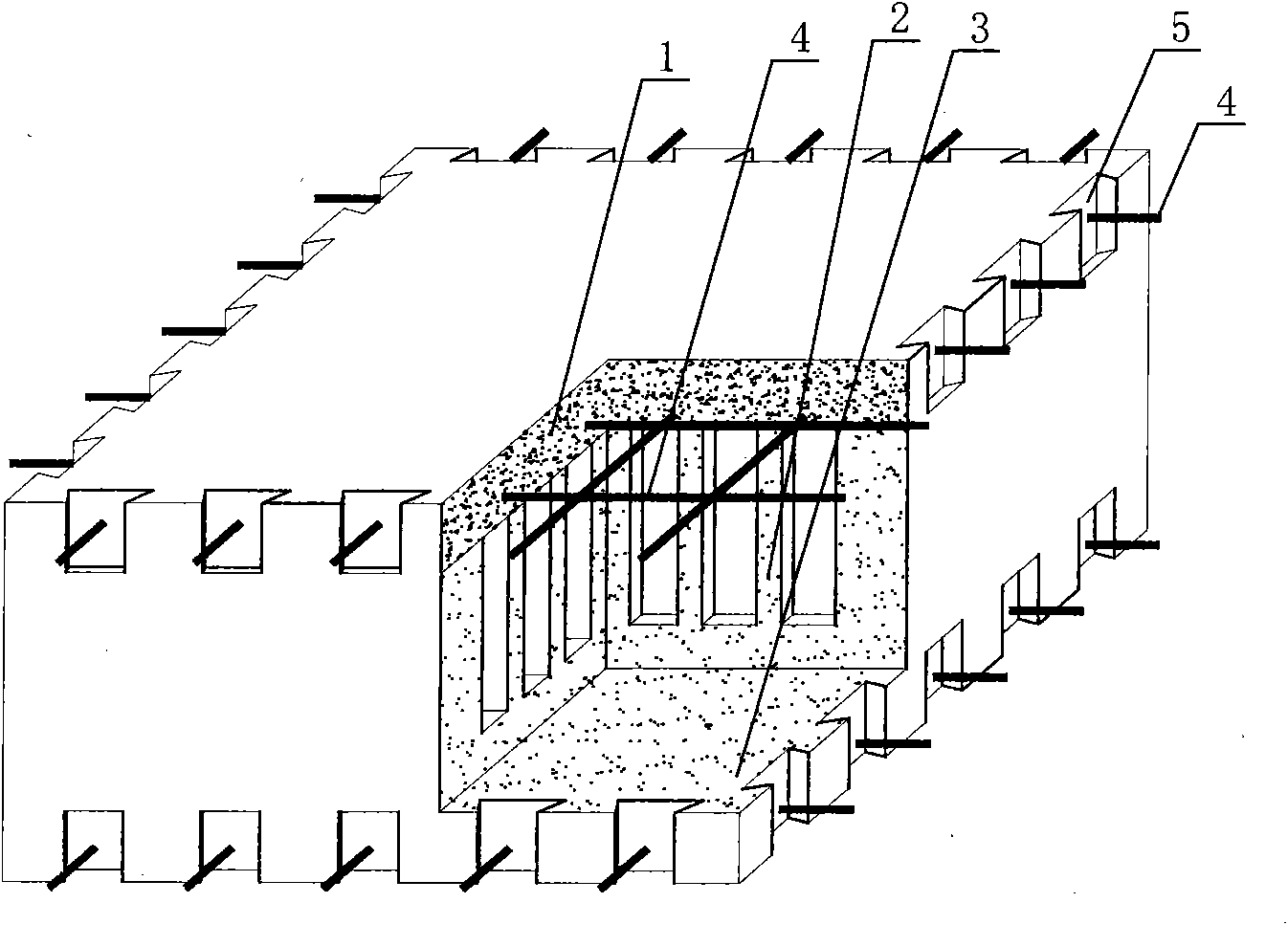

[0156] As shown in the accompanying drawings, the prefabricated panel unit of the present invention is composed of three layers of panels, including a top panel 1, a sandwich layer 2, and a bottom panel 3. The sandwich layer 2 is arranged between the top panel 1 and the bottom panel 3, and is characterized in that the top panel 1 and the bottom panel The bottom plate 3 is a load-bearing plate of reinforced concrete structure, in which steel bars 4 are arranged in a mesh shape, and the steel bars 4 protrude from the top plate 1 or / and the end surface of the bottom plate 3 is exposed to form the connecting rib steel bars 4, and the sandwich layer 2 is made of light materials. The hollow layer is formed, and the end surface of the top plate 1 or / and the bottom plate 3 is provided with a concave structure 5 or a convex structure 6 . In each drawing, 1 is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com