Oil-quenching air-cooling vacuum furnace

A vacuum furnace and oil quenching technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve problems affecting quality, inconvenient processing of workpieces, shaking of workpiece cars, etc., to achieve convenient operation, simple structure, and reduce shaking or derailment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

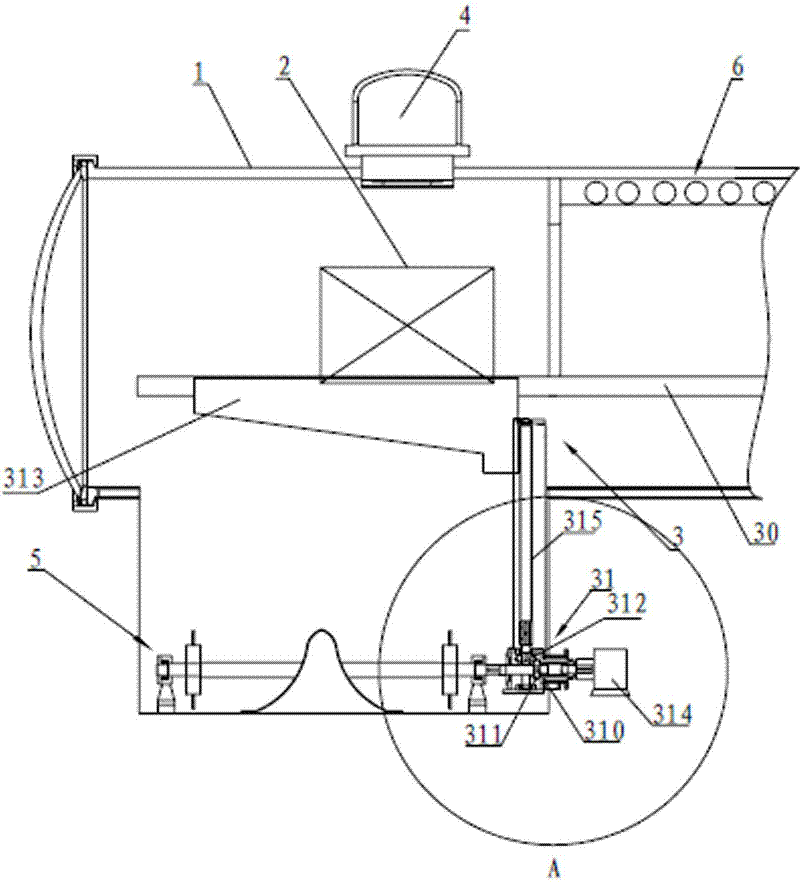

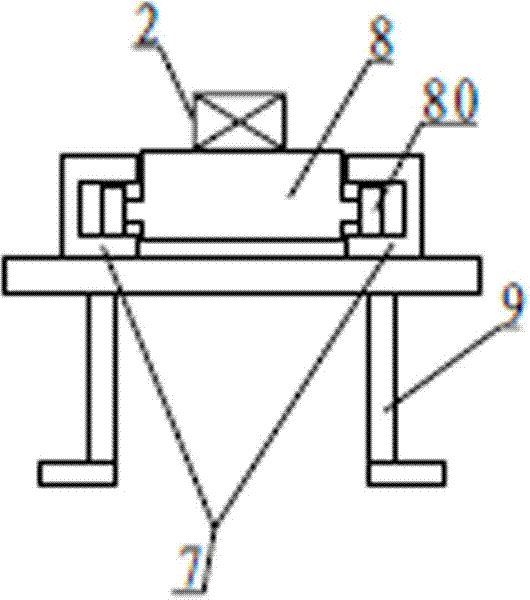

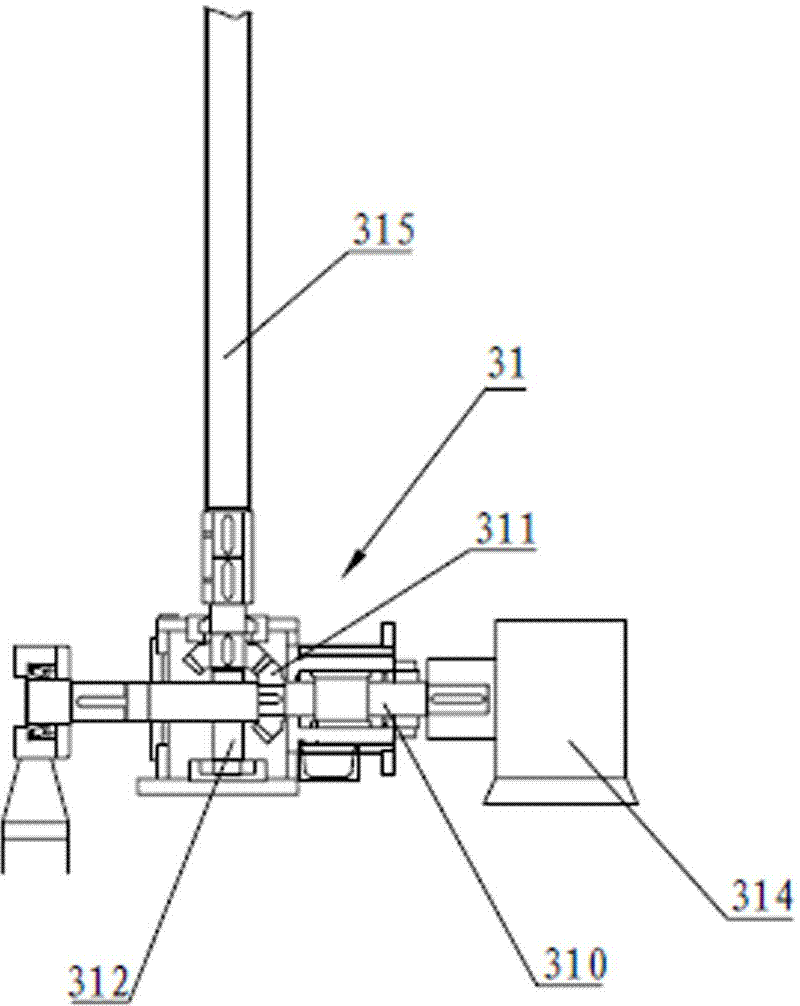

[0016] Such as figure 1 As shown, the oil-quenched air-cooled vacuum furnace according to this embodiment includes a furnace body 1, a conveying mechanism 3 for workpieces 2, a vacuum system 4, an oil-quenched processing system 5, a cooling system 6, and an electric control system (not shown in the figure) ), the conveying mechanism 3 includes a conveying device 30 in the horizontal direction of the workpiece 2 and a lifting device 31 in the vertical direction, wherein the conveying device 30 includes a double slide rail 7 and a double slide rail 7 arranged in the furnace body 1 for conveying the workpiece 2 Cooperating workpiece trolley 8 and rail support 9 for supporting double sliding track 7 and being fixed in the body of furnace 1, lifting device 31 comprises the first worm screw 310 that is arranged on the side bottom of body of furnace 1, and the first worm screw 310 phase Cooperating worm gear 311, the second worm screw 312 that cooperates with worm gear 311, the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com