Treatment method for stinky waste gas containing sulfides and hydrocarbons

A sulfide and exhaust gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as poor stability, tail gas discharge that cannot meet standards, and stricter requirements, so as to reduce load, improve utilization value, and improve The effect of treatment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

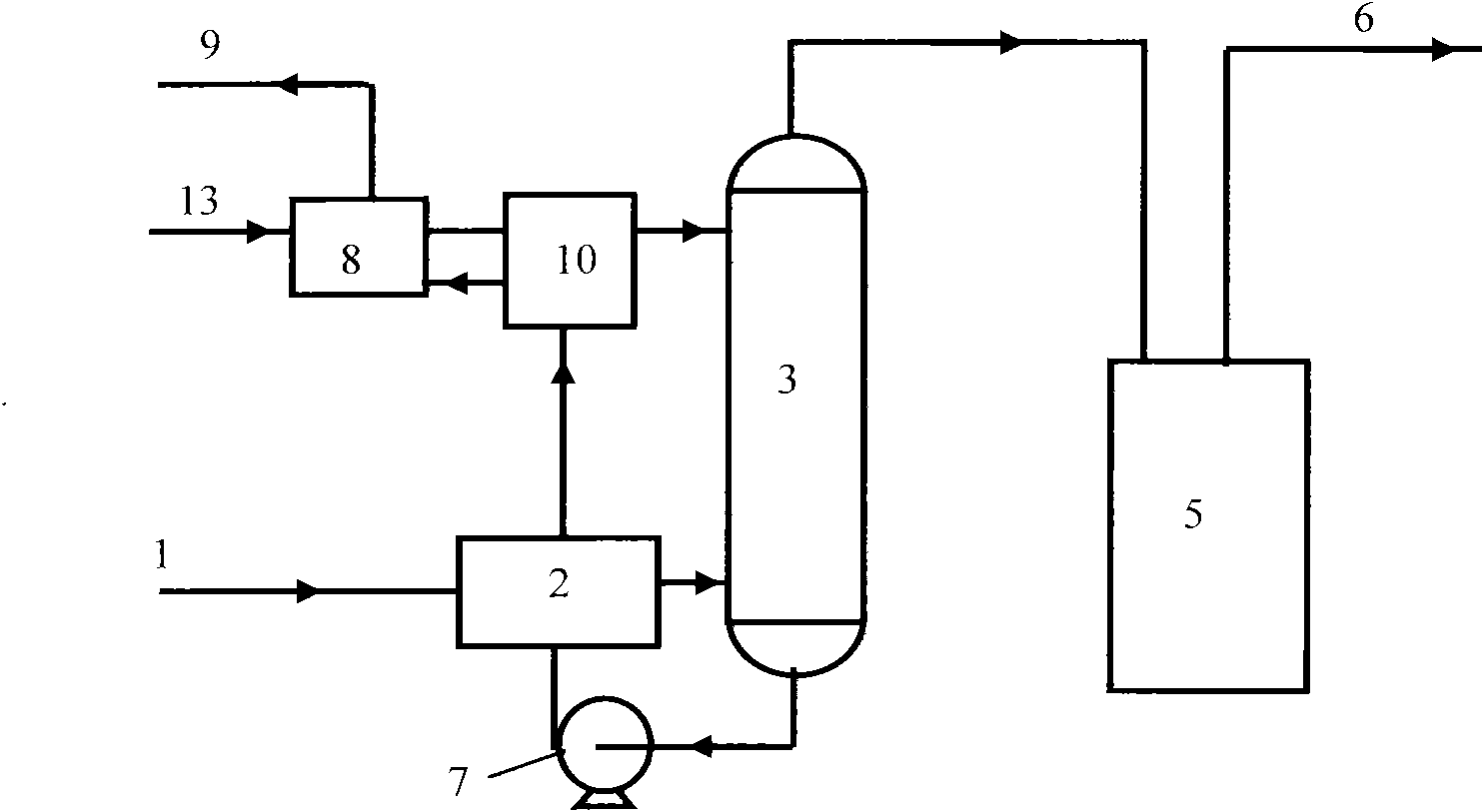

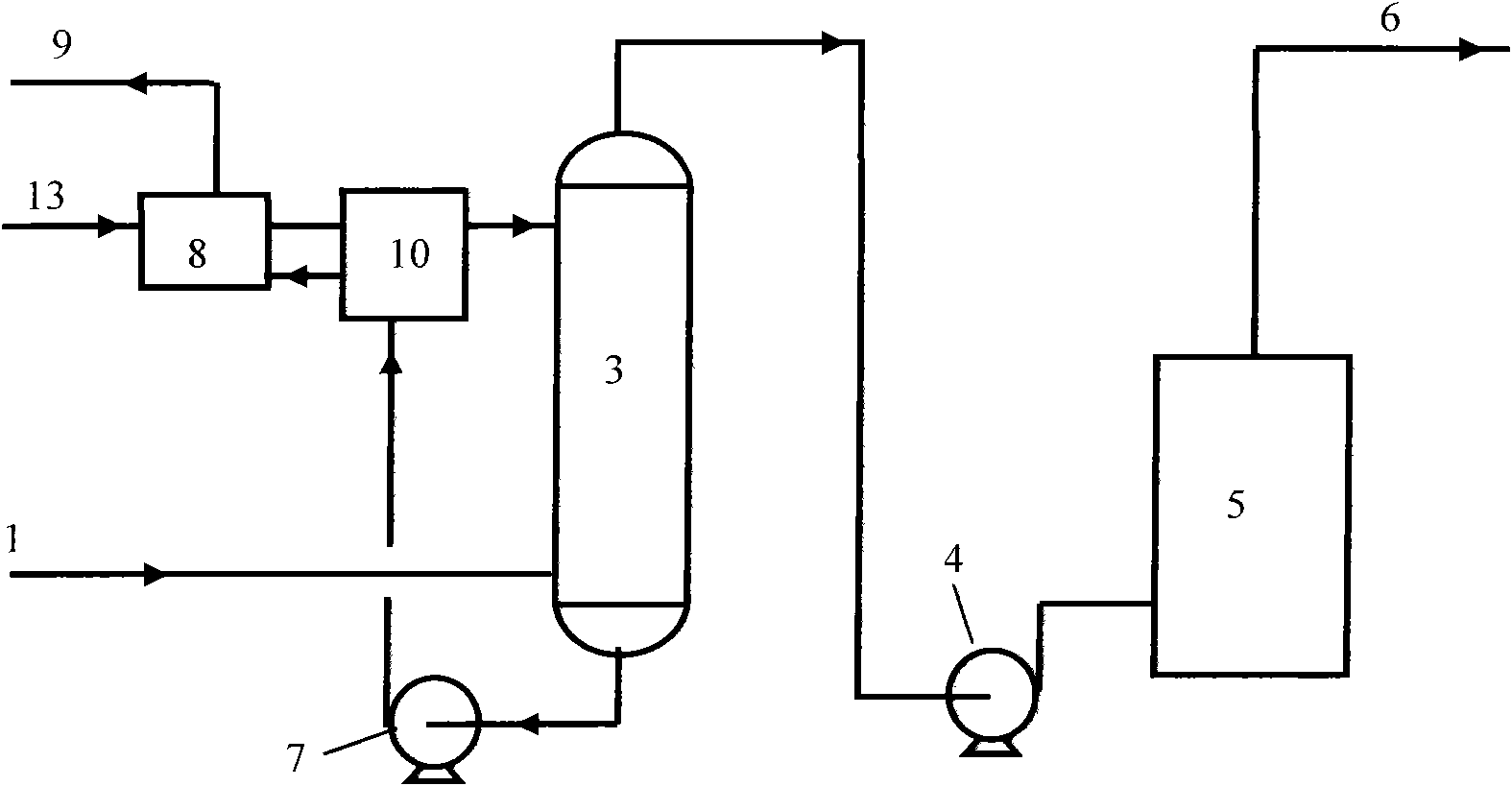

[0037] Hydrogen sulfide 2000mg / m3 in waste gas from sour water tank area of an oil refinery 3 , organic sulfide 150mg / m 3 , total hydrocarbon concentration 40×10 4 mg / m 3 , the flow rate is 200Nm 3 / h or so. use as figure 1 In the process flow shown, sodium hydroxide aqueous solution is used as the desulfurization absorption liquid in the desulfurization reactor, and fresh lye is replaced when the pH value of the working liquid drops to 9. The absorption tower is filled with Dg38 packing ring. The absorbent uses catalytic cracking gas oil fraction with a distillation range of 180-380°C, and the sulfur content in terms of sulfur mass is 0.8%. 3 / h at a temperature of 8°C. The rich absorbent discharged from the absorption tower is not regenerated, but directly used as the feed of the hydrotreating unit, which does not affect the normal operation of the hydrotreating unit, and can also increase the diesel yield of the hydrotreating unit.

[0038] After the malodorous ex...

Embodiment 2

[0040] According to the method described in Example 1, the absorption solvent used is FCC diesel with a sulfur content of 1.2%, the temperature of the absorption solvent diesel is 12°C, and other conditions are as described in Example 1.

[0041] After the malodorous waste gas is purified by the above process, the hydrogen sulfide purification rate in the waste gas is 100%, the organic sulfide removal rate is 99.9%, and the total hydrocarbon removal rate is >95%. The device has been continuously operated for 300 days, and the removal rate is stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com