Split cycle reciprocating piston engine

A piston engine, reciprocating technology, applied to internal combustion piston engines, engine components, combustion engines, etc., can solve problems such as large delays, methods that cannot provide energy storage or recovery, and reduction of engine power output rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

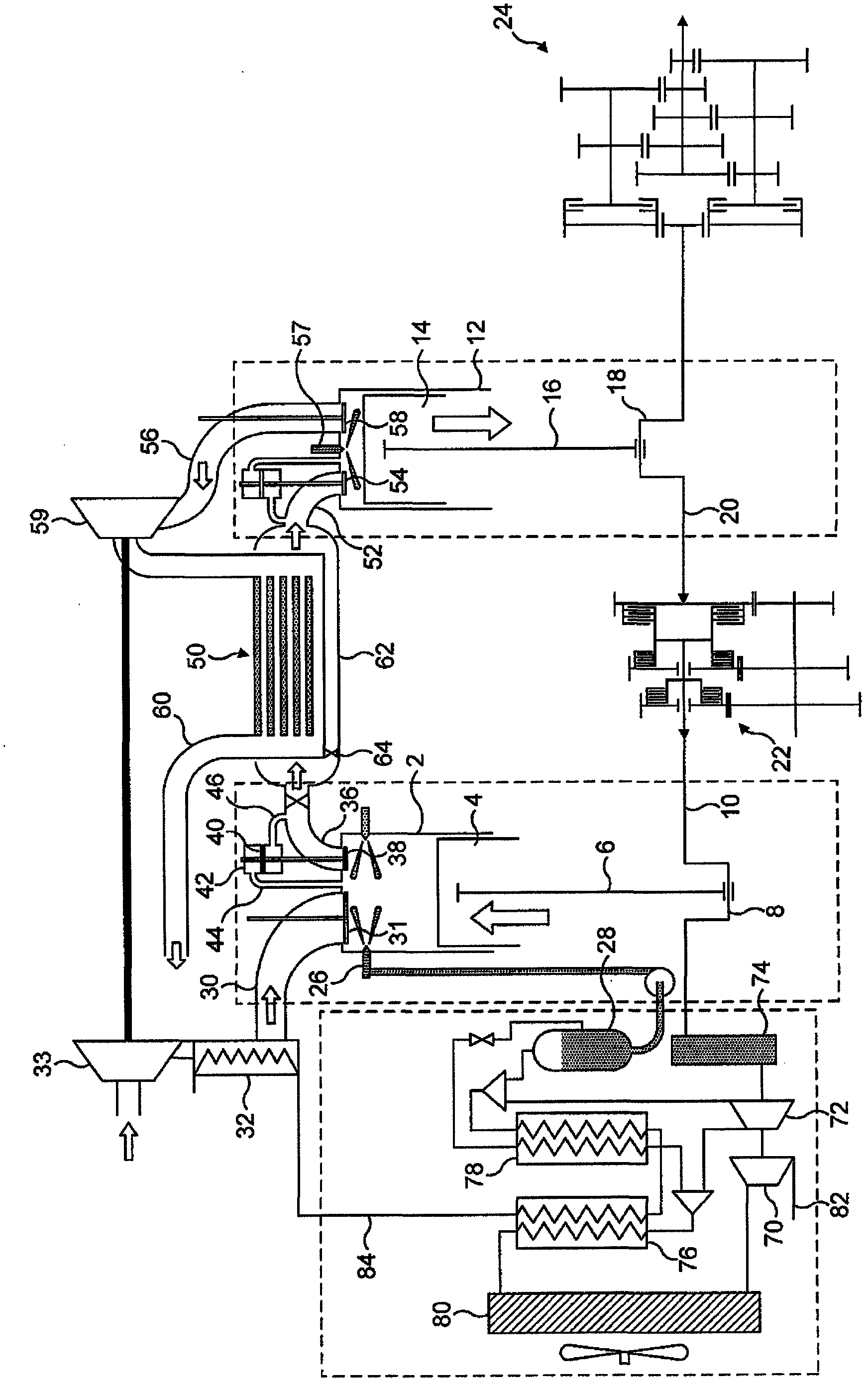

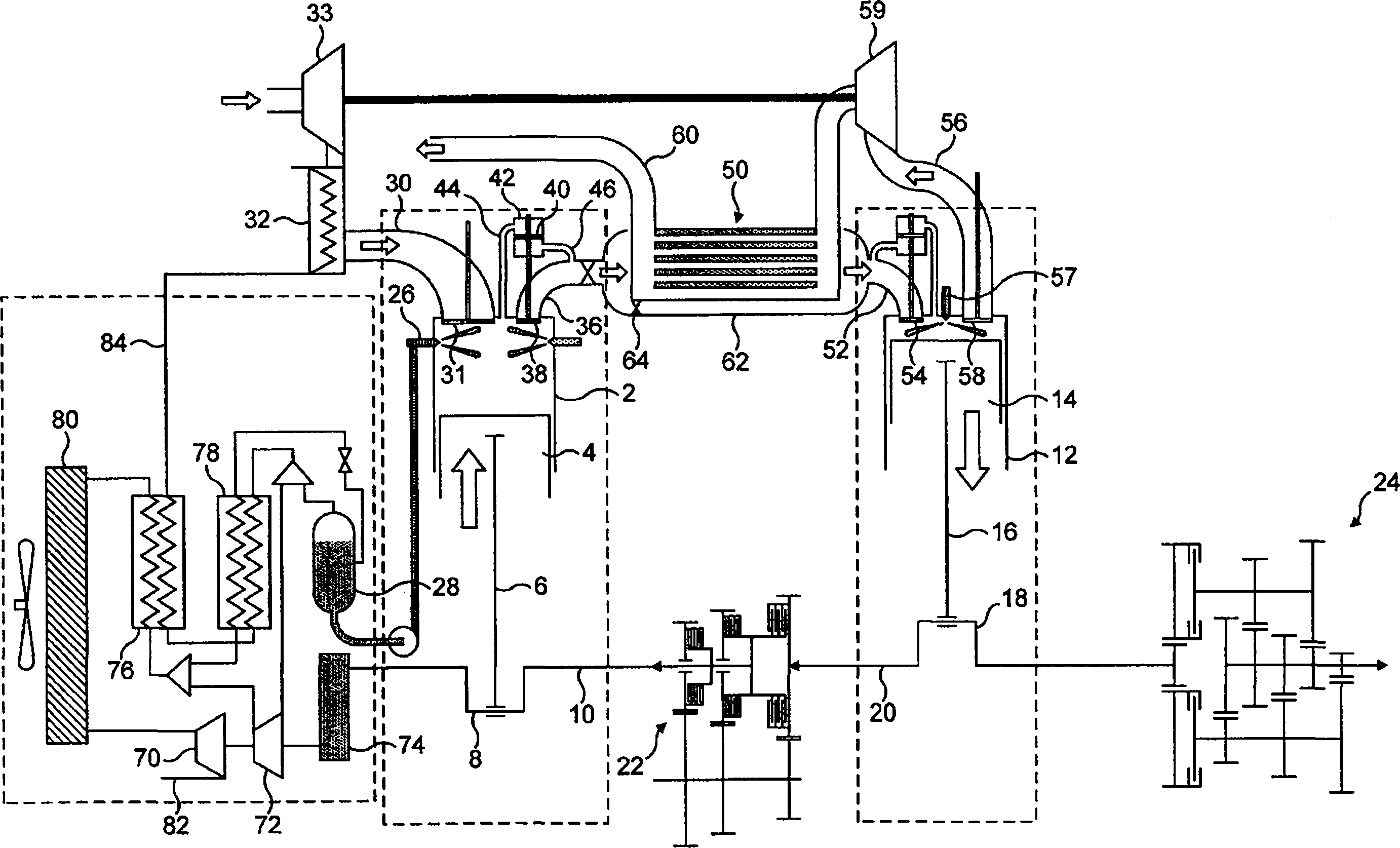

[0019] As shown, the engine comprises a compression cylinder 2 housing a compression piston 4 connected by a connecting rod 6 to a corresponding crank 8 on a portion 10 of the crankshaft. The engine also comprises an expansion cylinder 12 housing an expansion piston 14 connected by a connecting rod 16 to a corresponding crank 18 on another part 20 of the crankshaft. Although only one compression cylinder 2 and one expansion cylinder 12 are shown, it should be understood that there may be any desired number of such cylinders and that furthermore the number of compression cylinders need not be the same as the number of expansion cylinders, and that the dimensions of the two types of cylinders It doesn't have to be the same either. The two parts 10, 20 of the crankshaft are not integrally connected together to rotate at the same speed as conventional, but are connected by a transmission or gearbox 22 with optionally variable ratios. The crankshaft 10, 20 is also connected to a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com