Fastener element for concealed slide fasteners

A technology for zippers and chain teeth, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of easy damage, beautiful appearance, flying broken pieces, increased operation and material costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

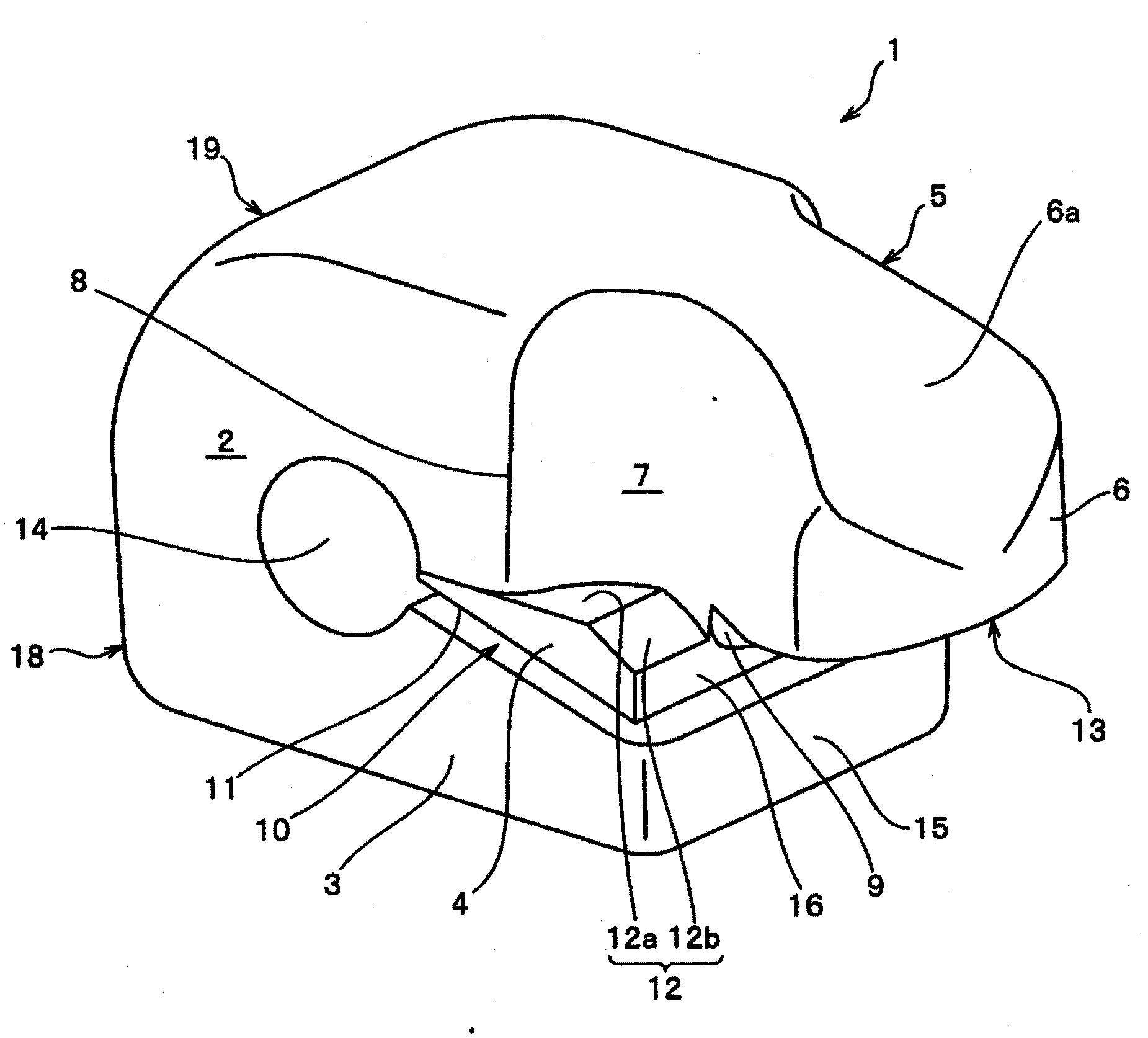

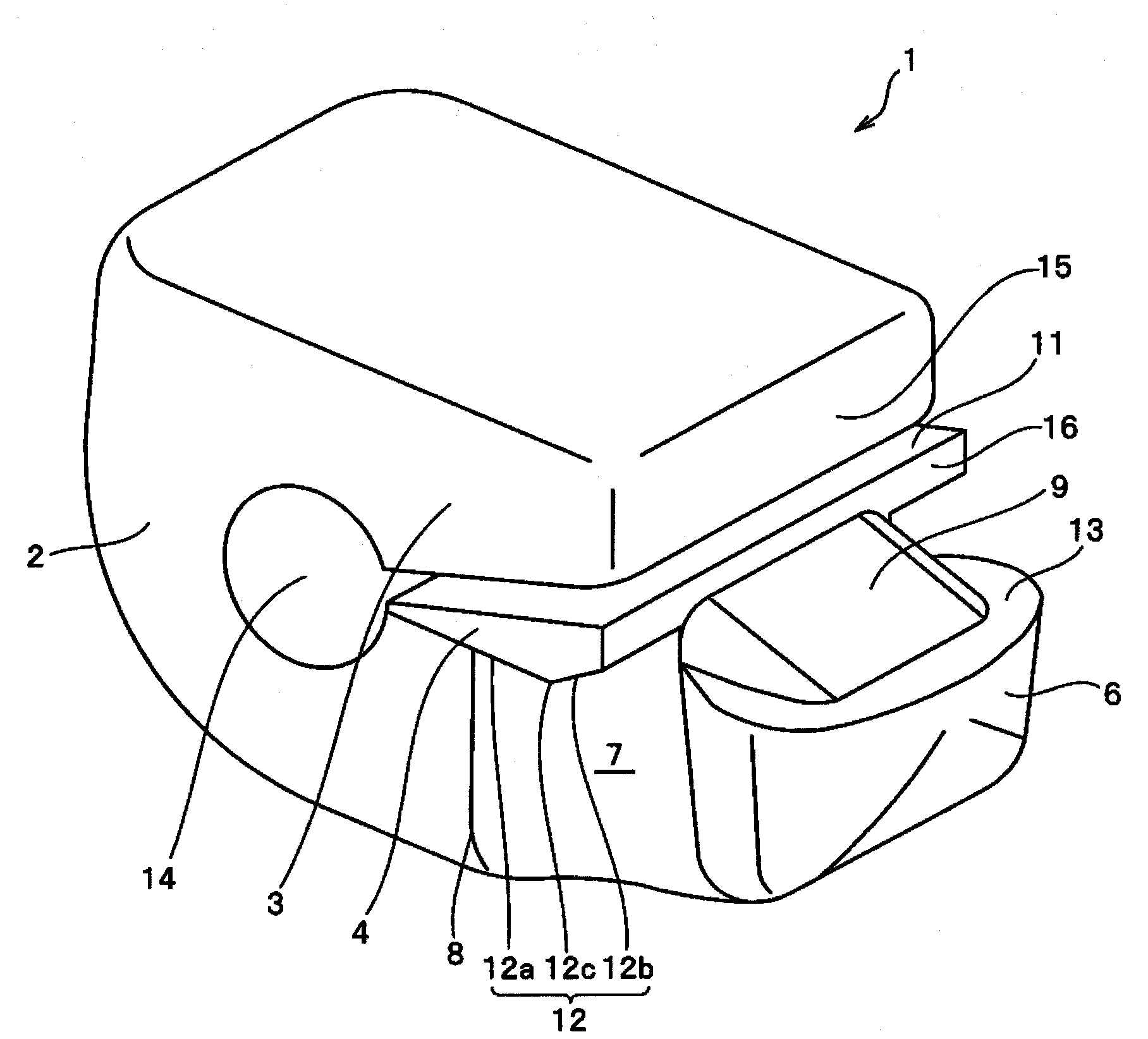

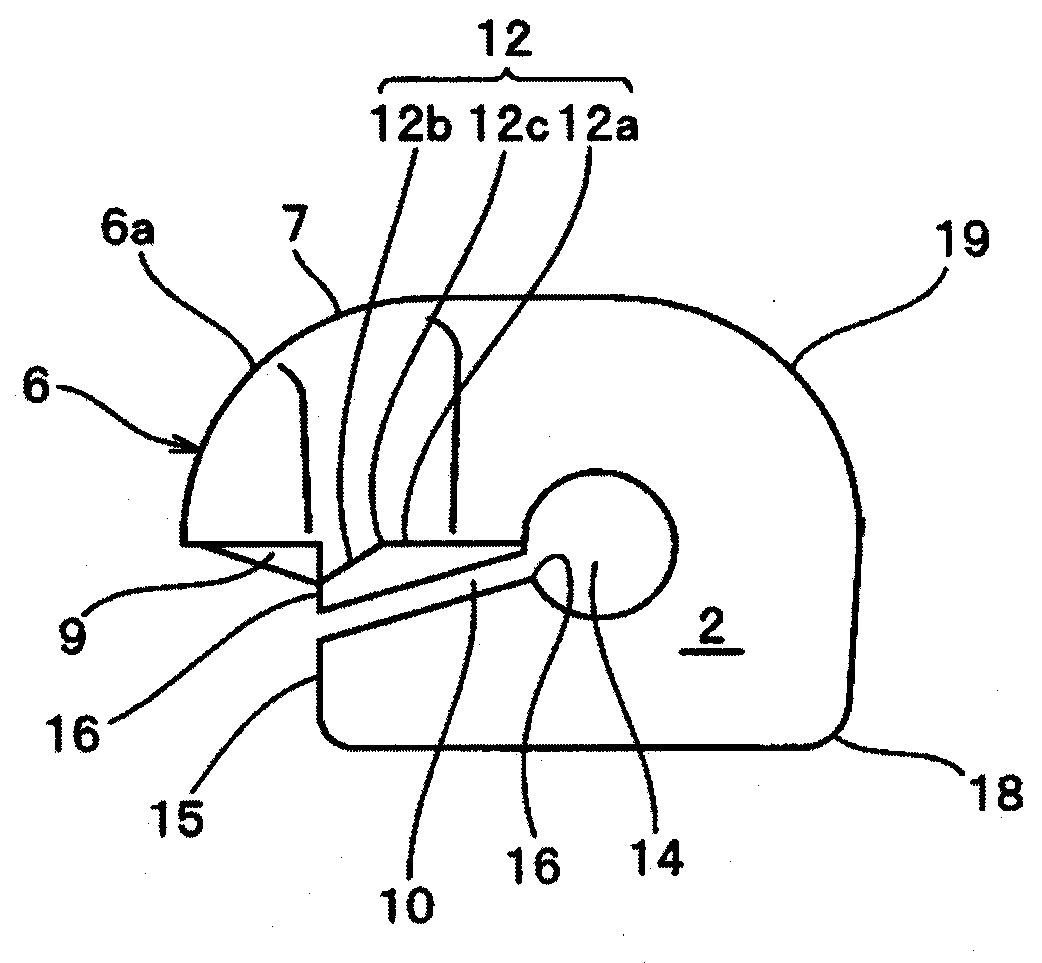

[0053] figure 1 It is a perspective view viewed from the element exposure side showing the entire fastener element of the first embodiment of the present invention, figure 2 is a perspective view of the zipper element viewed from the hidden side of the element, image 3 is a side view of the zipper element. in addition, Figure 4 is a side view of the state where the zipper elements are engaged, Figure 5 It is a side view which shows the state at the time of disengagement when the lateral pull force of the fastener tape of left and right acts on this meshing fastener element. Figure 6 yes Figure 5 The enlarged section view of the main part.

[0054] The fastener element 1 is formed to have a tape side edge mounting groove 10 for attaching the tape side edge of the fastener tape 22 in a substantially U-shape as a whole, and the fastener element 1 has a string portion that holds the fastener tape 22 The C-shaped base 2 of 25, the flat plate-shaped first band clamping p...

Embodiment 2

[0067] Figure 6 The 2nd Example of the fastener element of this invention is shown. Also in this Example, the structure of the main part of the fastener element 1 does not substantially change from the said 1st Example. The characteristic structure in this embodiment lies in the point that the relative dimensional relationship between the engaging head 6 and the neck 7 of the fastener element 1 is defined. Therefore, in the following description, the same names and reference numerals are used for the names and reference numerals of parts substantially corresponding to those of the above-mentioned first embodiment.

[0068] Such as Figure 6 As shown, the engaging portion 5 of the fastener element 1 has a neck portion 7 and an oval engaging head portion 6 in plan view, and the neck portion 7 becomes thinner in the center from the long diameter portion of the engaging head portion 6 and becomes C-shaped. A shoulder 8 extends from the top face of the base 2 and the neck 7 is ...

Embodiment 3

[0071] Figure 7 and Figure 8 A fastener element for a concealed slide fastener according to a third embodiment of the present invention and its state during rotation are shown.

[0072] In this embodiment, the difference from the above-mentioned first and second embodiments is that, compared with the first embodiment and the second embodiment, the engaging surface 12 of the second belt clamping portion 4 is in surface contact with each other. The upper surface 13 ( figure 2 upper surface) is formed as a plane, and the upper surface 13 and the elliptical peripheral side are orthogonal to each other, in this embodiment, as Figure 7 and Figure 8 As shown, at least the ridgeline portion of the top end of the engaging head 6 is perpendicular to the engaging direction to form a chamfered portion 6b. As the chamfered portion 6b, the case where it is set as a curved surface can be cited, but it may also be as Figure 13 Shown is an inclined surface sloping towards the top en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com