High-performance integrated electromagnetic interference (EMI) filter

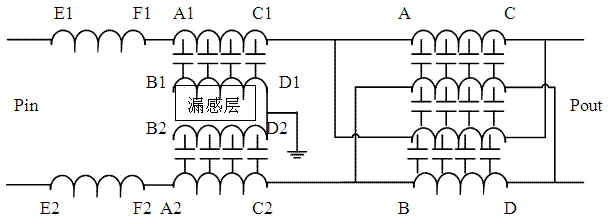

A filter and high-performance technology, applied in the direction of electrical components, impedance networks, etc., can solve the problem of increasing the facing area of the single-turn copper wire windings on both sides of the dielectric board in the differential mode capacitor module, and the difficulty of integrating the differential mode capacitor value to reach the ideal value , increase the plane area of the filter, etc., to achieve the effect of enhancing the ability to resist external electromagnetic interference, improving the utilization rate of the magnetic core, and increasing the insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

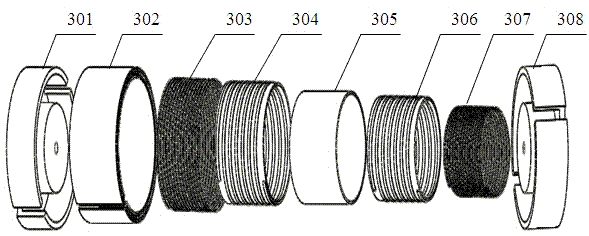

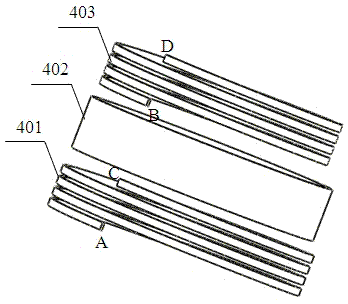

[0023] Such as Figure 1A As shown, the present invention provides a high-performance integrated EMI filter, including a first pot-type magnetic core 301, a differential mode capacitor 302, a first common mode inductor 303, a first integrated LC structure 304, and a leakage inductance arranged coaxially in sequence. layer 305, a second integrated LC structure 306, a second common-mode inductor 307, and a second can-shaped magnetic core 308. The first and second can-shaped magnetic cores 301, 308 can be interlocked to form an accommodating cavity, so that The rest of the parts are fastened in the accommodating cavity, and the first and second pot-type magnetic cores 301, 308 are all made of ferrite materials with a magnetic permeability of 2000-5000 (the magnetic permeability of 2000 is selected in this embodiment. ferrite material), its ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com