Rotor paper insertion equipment

A technology of rotor and paper insertion, which is applied in the direction of laying solid insulation, etc., can solve problems such as lack of molding and affect the popularization and application of new insulating paper, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

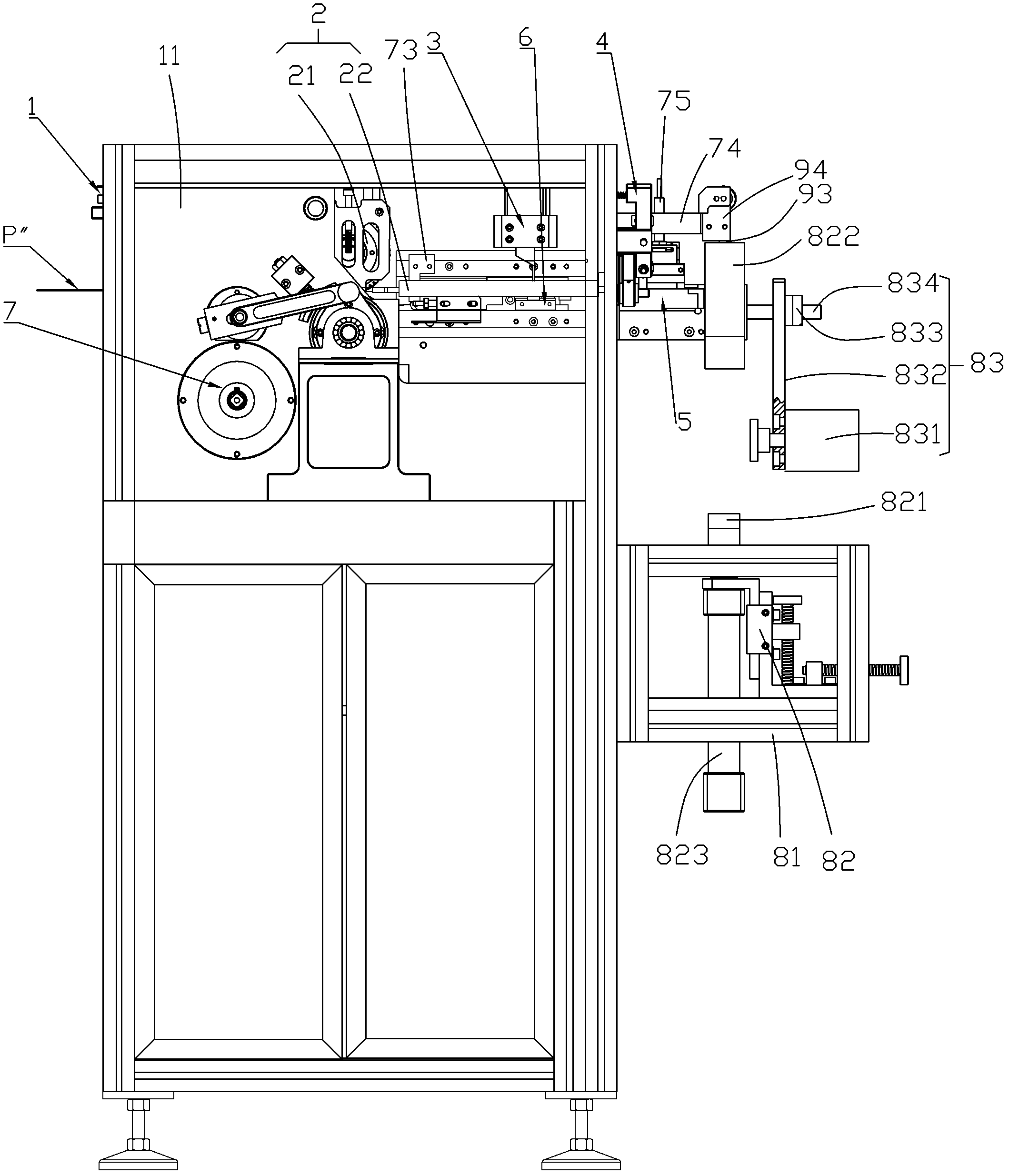

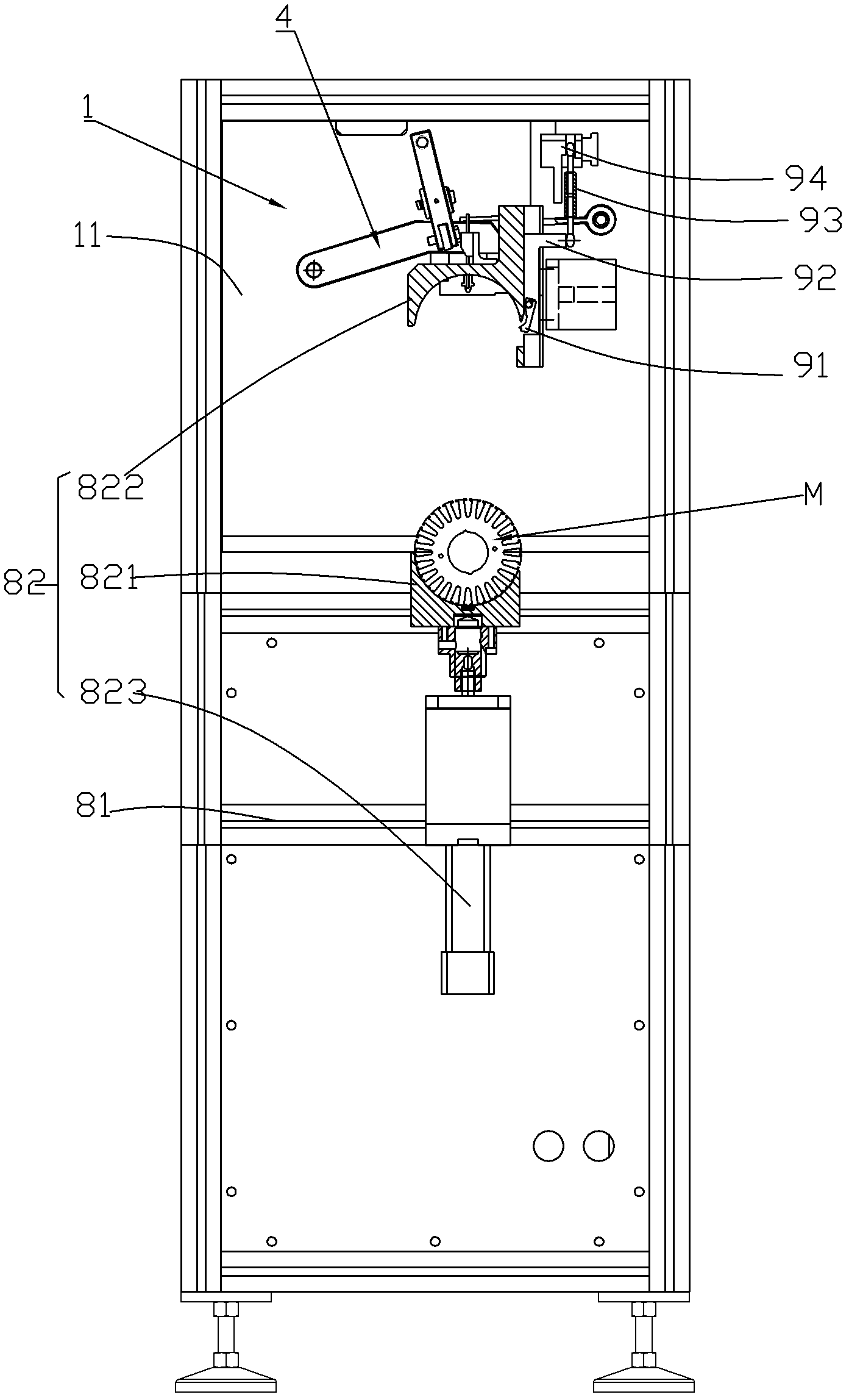

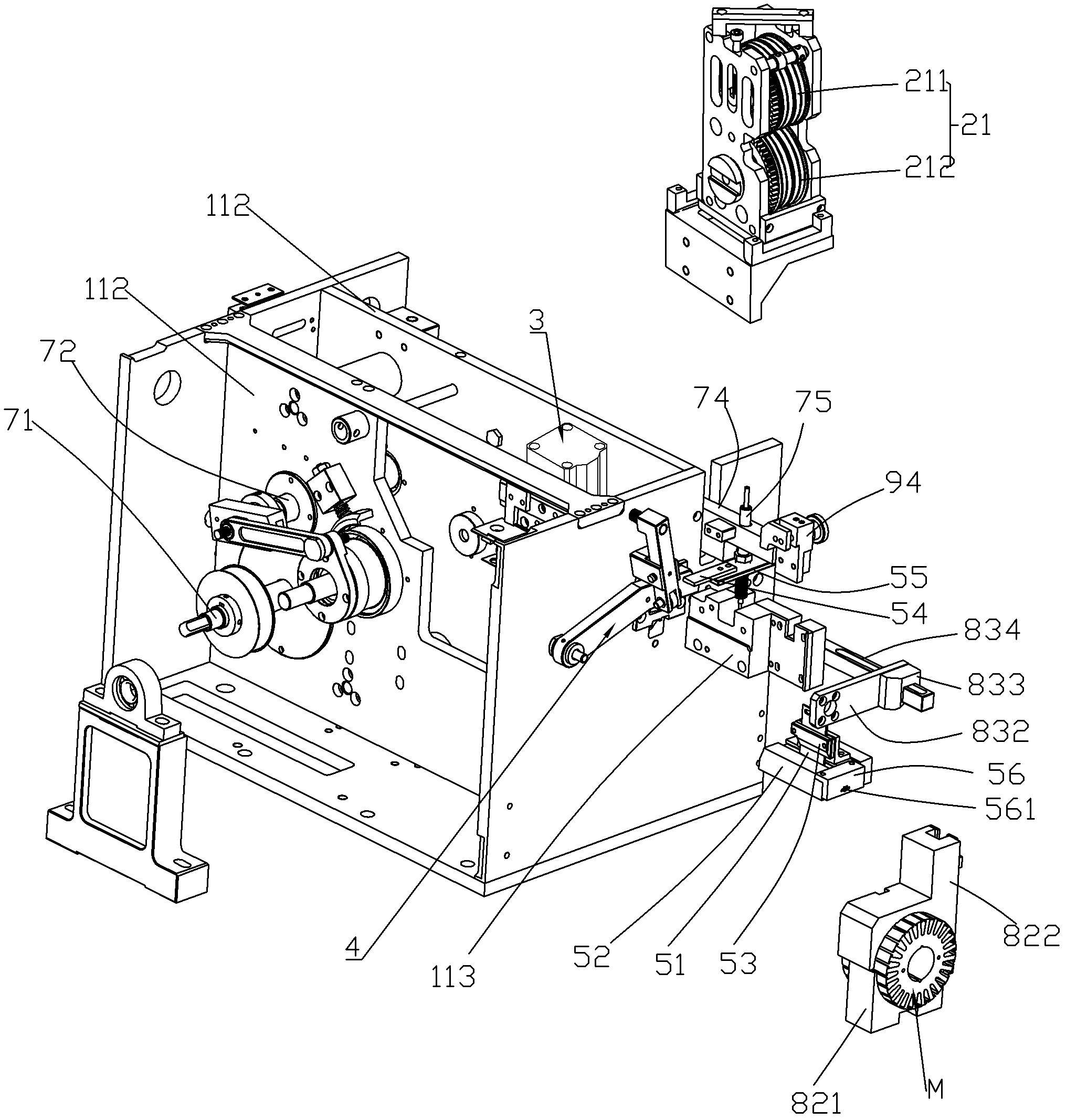

[0036] Such as Figure 1 to Figure 12 As shown, the embodiment of the present invention provides a rotor paper insertion device, the rotor paper insertion device includes a frame 1, a paper feeding device 2, an insulating paper leader forming device 3, a paper cutting device 4, a paper folding device 5, and a The main machine composed of the paper insertion device 6 of the push rod 61 and the driving device 7 containing the driving shaft 71 and the driven shaft 72, the rotor clamping device 8, the rotor indexing device 9 and the control system; the rotor M is installed on the rotor On the clamping device 8, the insulating paper tape P" is cut to form a semi-finished insulating paper P', which is then bent and formed to form a finished insulating paper P.

[0037] The frame 1 is provided with a main frame 11 for installing the main frame. The support support seat 113 on the top; the frame 1 is also provided with a photosensitive shield, an operation display screen and an insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com