High-speed straw bale breaking feeding machine

A feeder and unpacking technology, which is applied in the field of feeding equipment in front of a biomass power plant, can solve the problems of non-standard operation, large demand, easy winding, etc., and achieve the effect of ensuring continuous safe operation and good dredging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

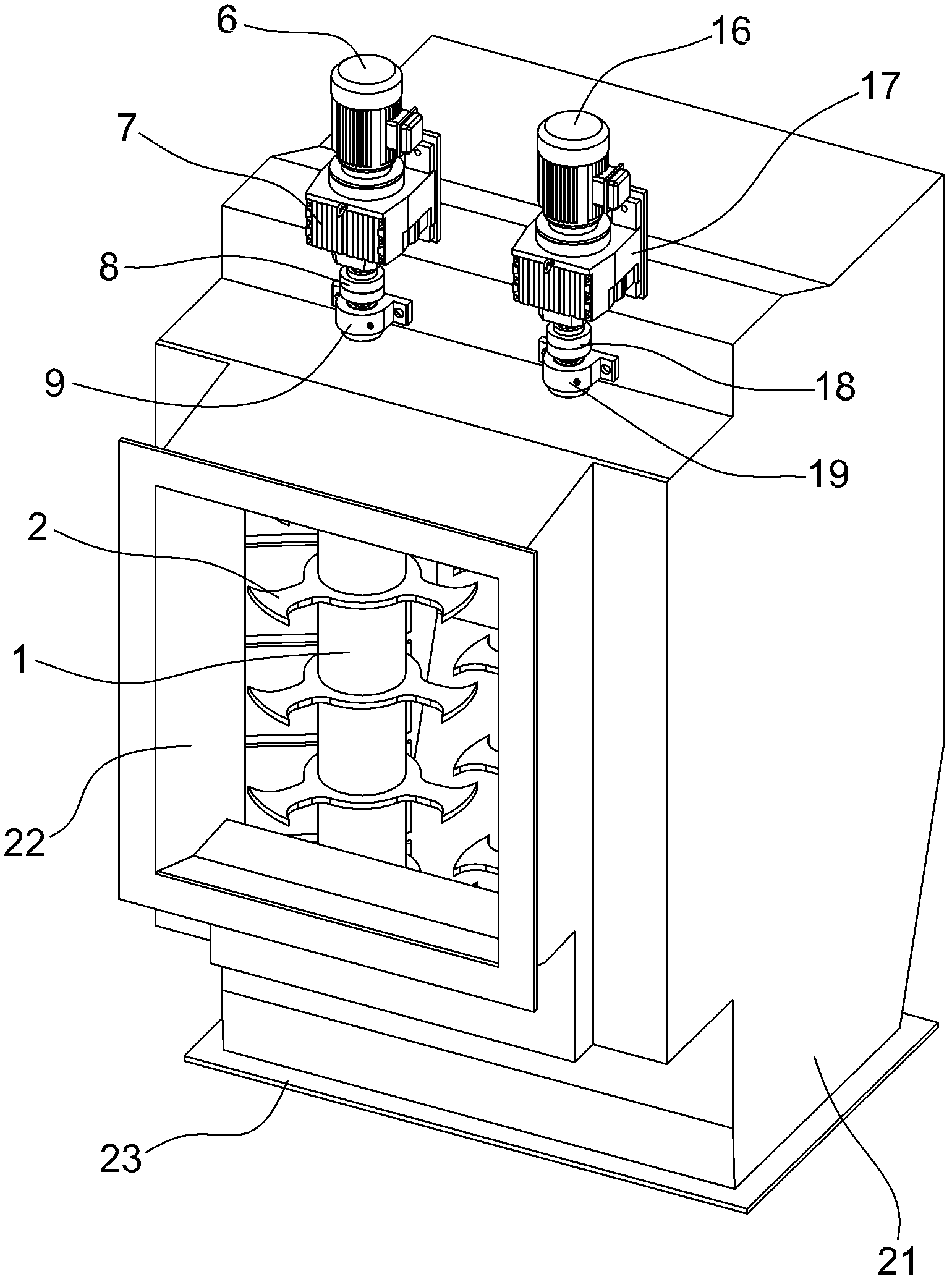

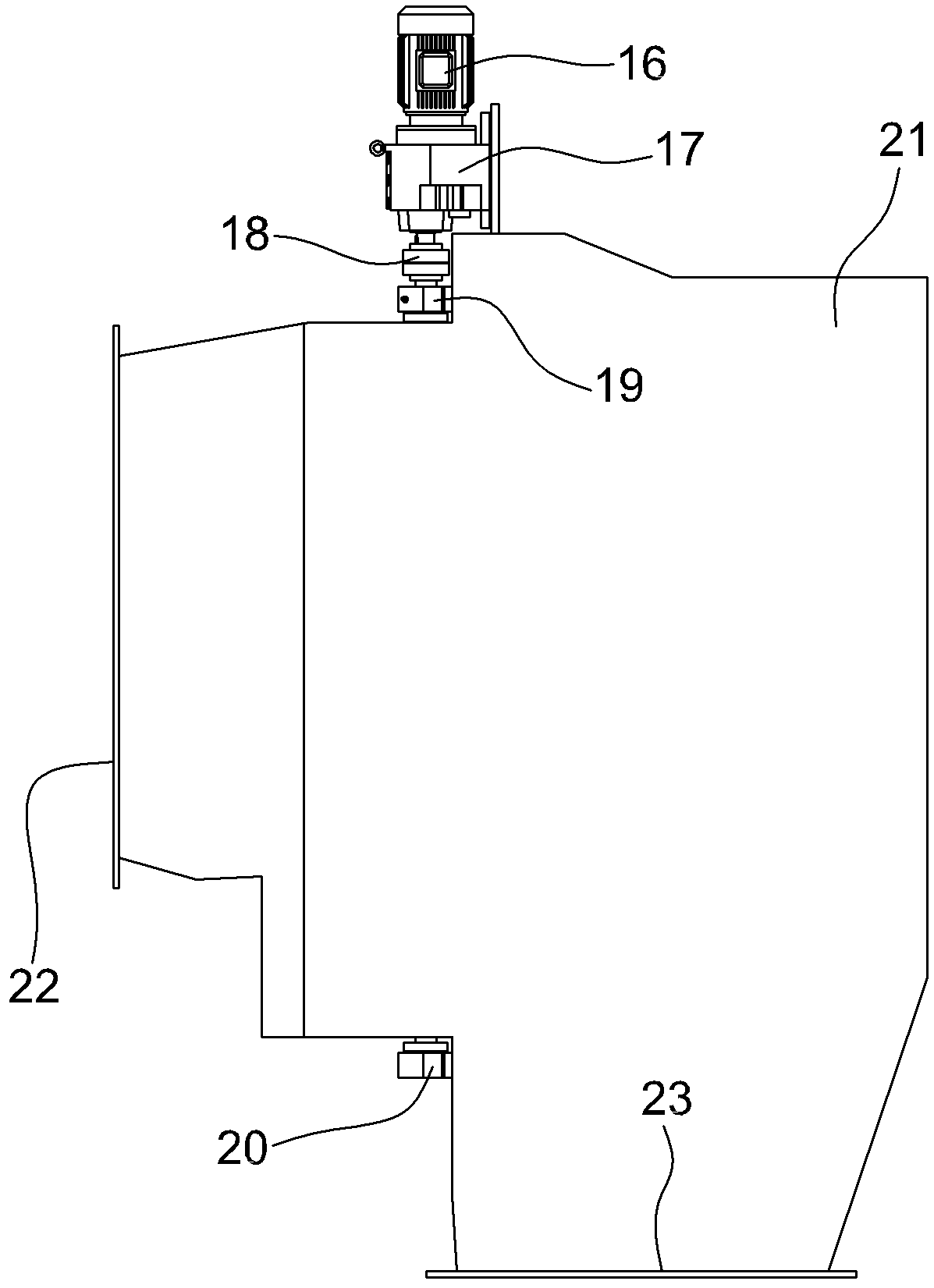

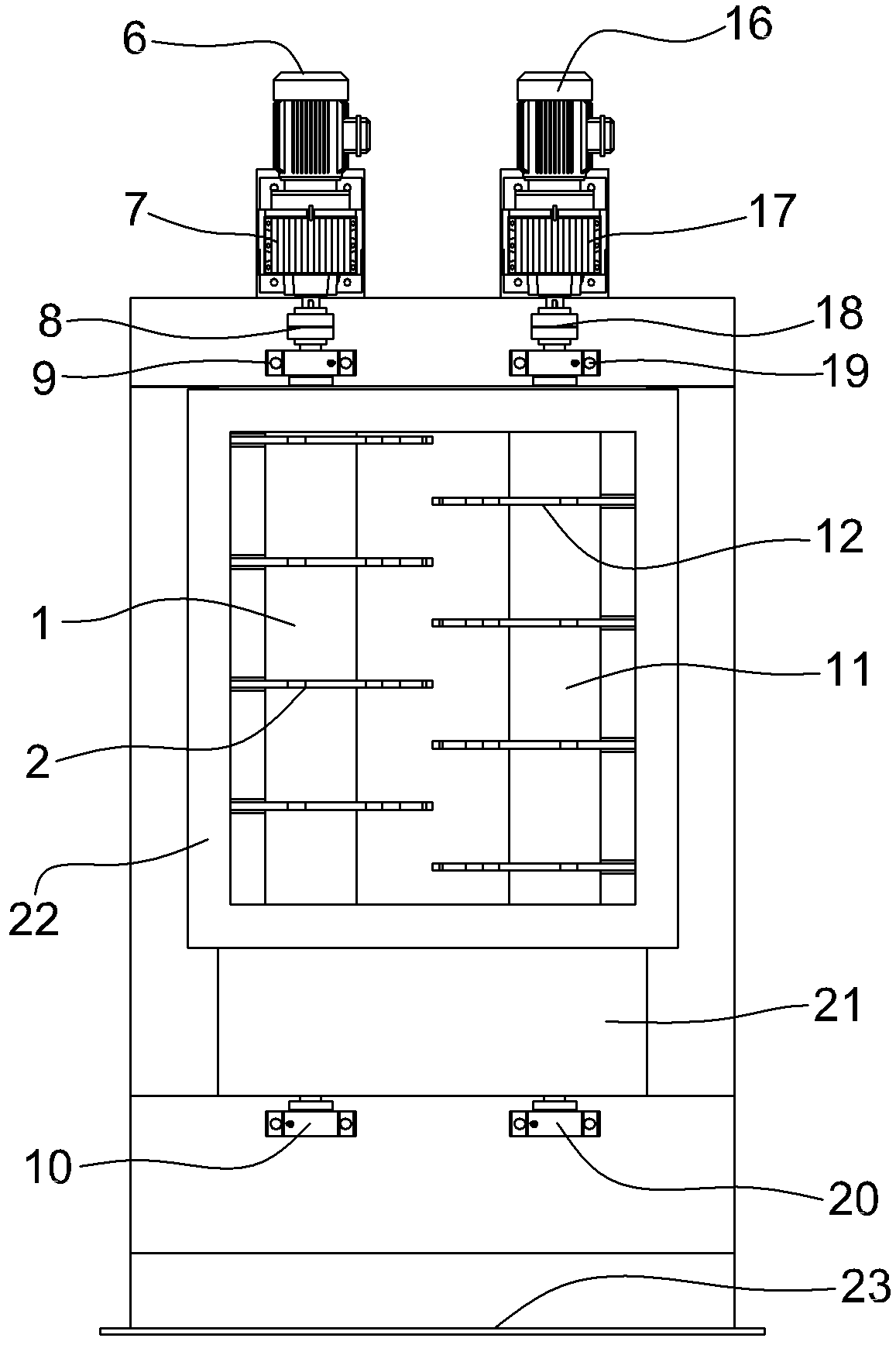

[0032] Number in the figure

[0033] 1Left roller shaft 2Left-handed cutting and unwrapping piece 3Knife flap

[0034] 4Left cleaning knife 5Left knife slot 6Left motor

[0035] 7Left reducer 8Left coupling 9Bearing

[0036] 10 bearing

[0037] 11 Right roller 12 Right-handed cutting and unpacking sheet 13 Knife flap

[0038] 14 Right cleaning knife 15 Right knife slot 16 Right motor

[0039] 17 Right reducer 18 Right coupling 19 Bearing

[0040] 20 bearings

[0041] 21 housing 22 feed port 23 discharge port

[0042] 24 knife holder 25 scraper 26 bolt

[0043] 27 nut 28 bolt hole 29 straw bag

[0044] 30 tool arm 31 tool head 32 tool tip

[0045] 33 knife point 34 nylon rope 35 base

[0046] 36 bolt 37 nut 38 left side wall

[0047] 39 Right side wall 40 Bolt 41 Nut

[0048] 42 base

[0049] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , The present invention is a high-speed straw unpacking feeder, including a housing 21, the front end of the housing 21 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com