Section assembling bridge girder erection machine

A bridge erecting machine and segmental technology, which is applied in the field of small-sized cantilever assembled bridge erecting machines, can solve the problems of increasingly stringent size and rigidity requirements, increased section height, increased equipment costs, and transportation difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

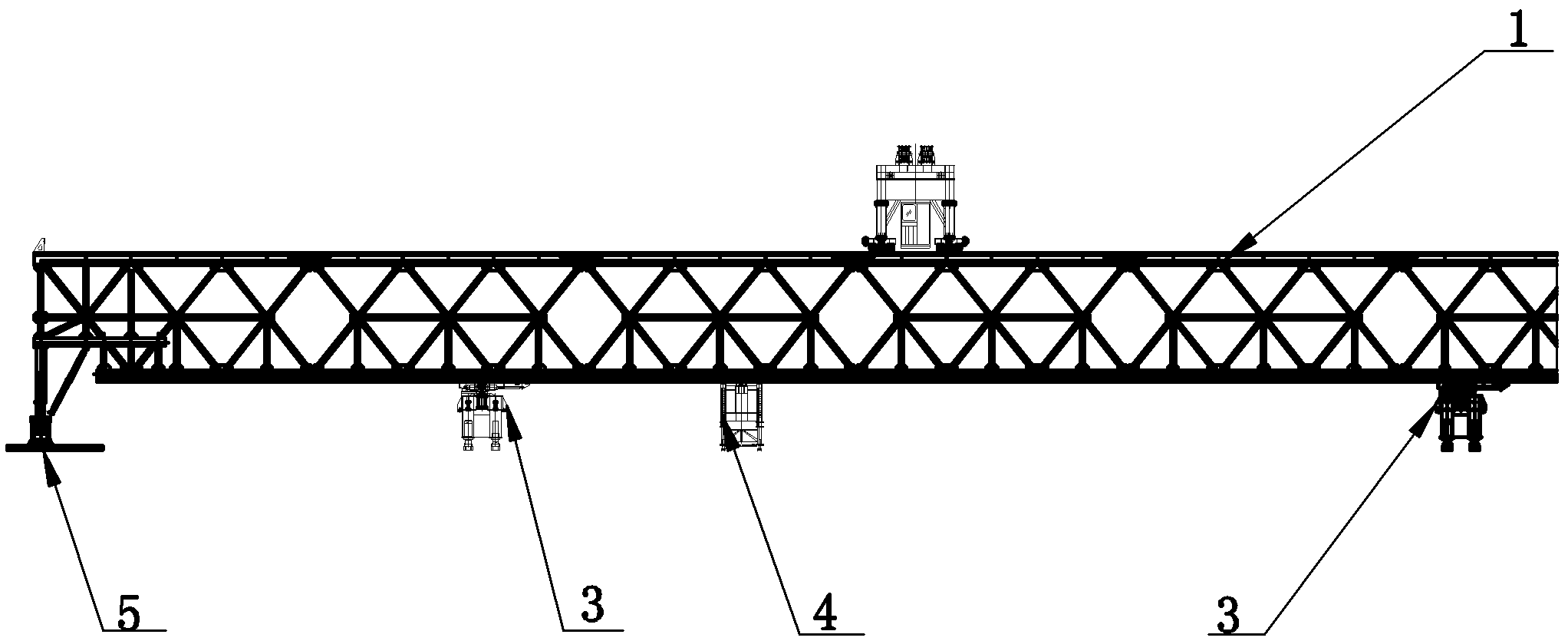

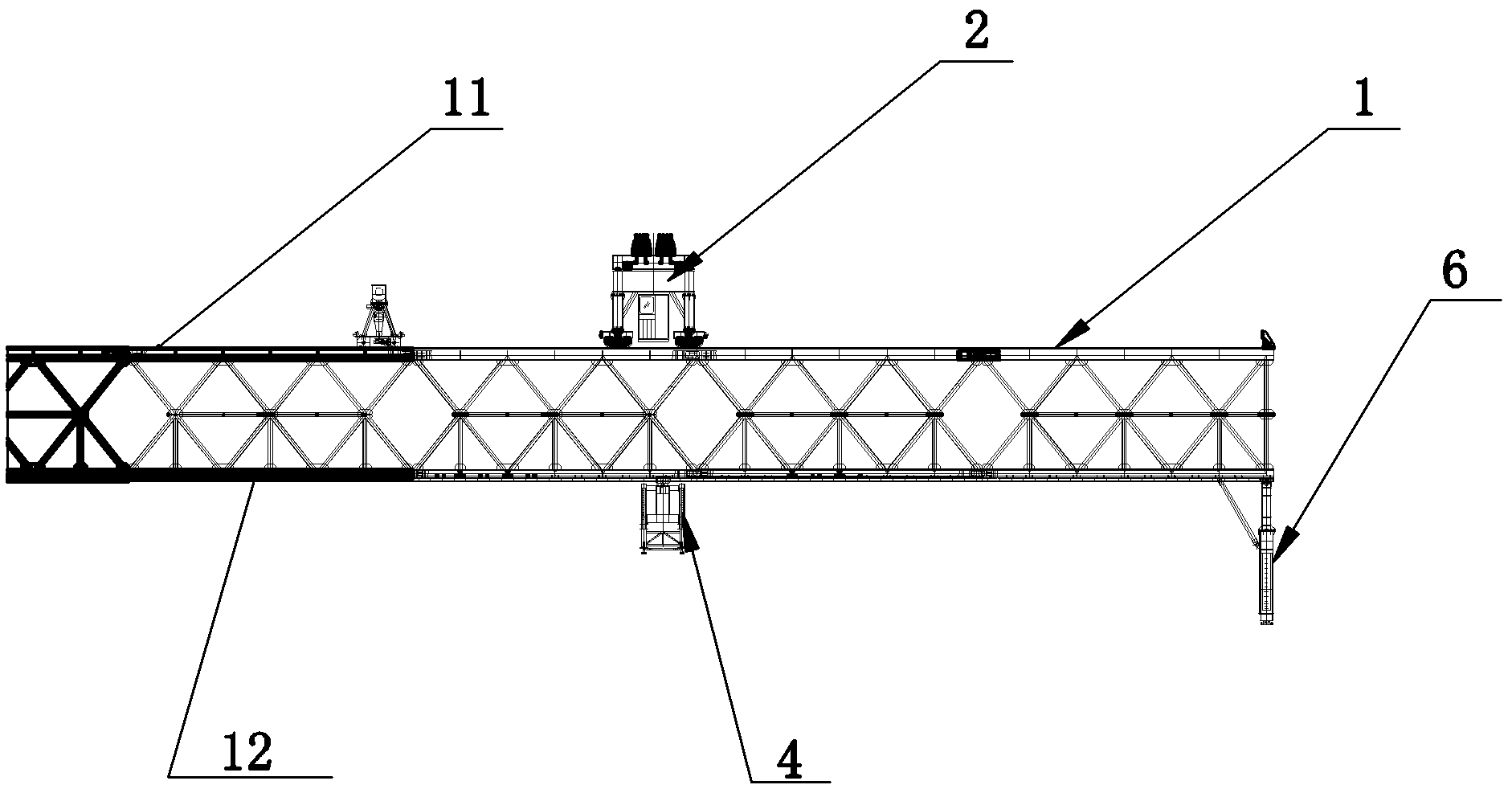

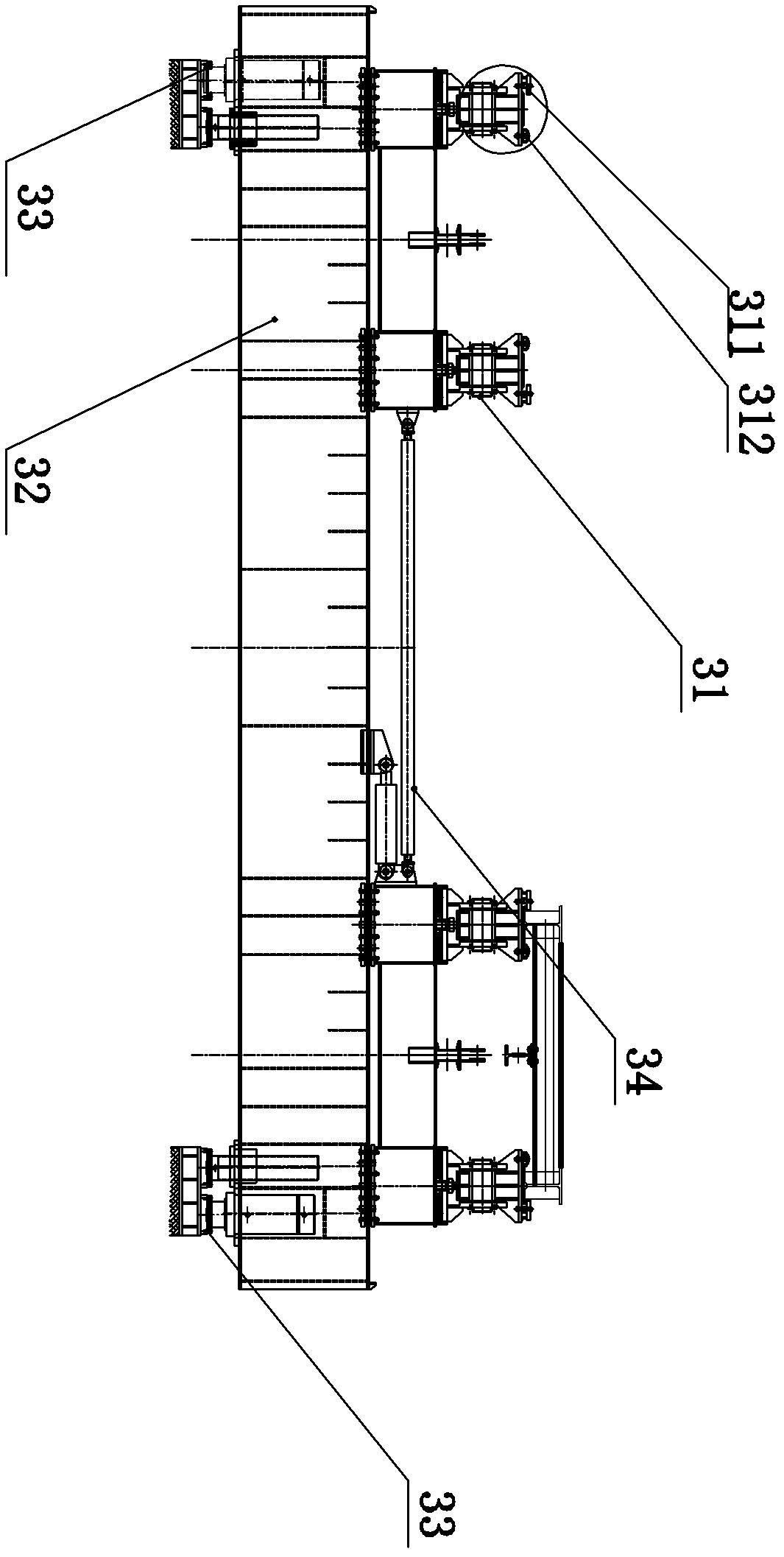

[0027] Such as figure 1 — Figure 14 As shown, a segmental assembly bridge erecting machine includes a frame 1 with a bridge running channel. The upper and lower sides of the frame 1 are respectively provided with rails 11 and 12, and the upper rail 11 is provided with a lifting frame. The device 2 lifts the object through the lifting device 2, and the lifting device 2 is arranged on the track 11, so the object can be moved; the lower track 12 is provided with a middle leg 3 and an auxiliary leg 4, The two ends of the frame 1 are respectively provided with a front support leg 5 and a rear support leg 6 . By setting the middle leg 3 and the auxiliary leg 4 on the track 12 of the frame 1, the center leg 3 and the auxiliary leg 4 can be moved conveniently, so that the frame 1 can be moved conveniently.

[0028] In the embodiment of the present invention, the lower rails 12 of the frame 1 are divided into two groups, and each group of rails 12 is composed of two guide rails, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com