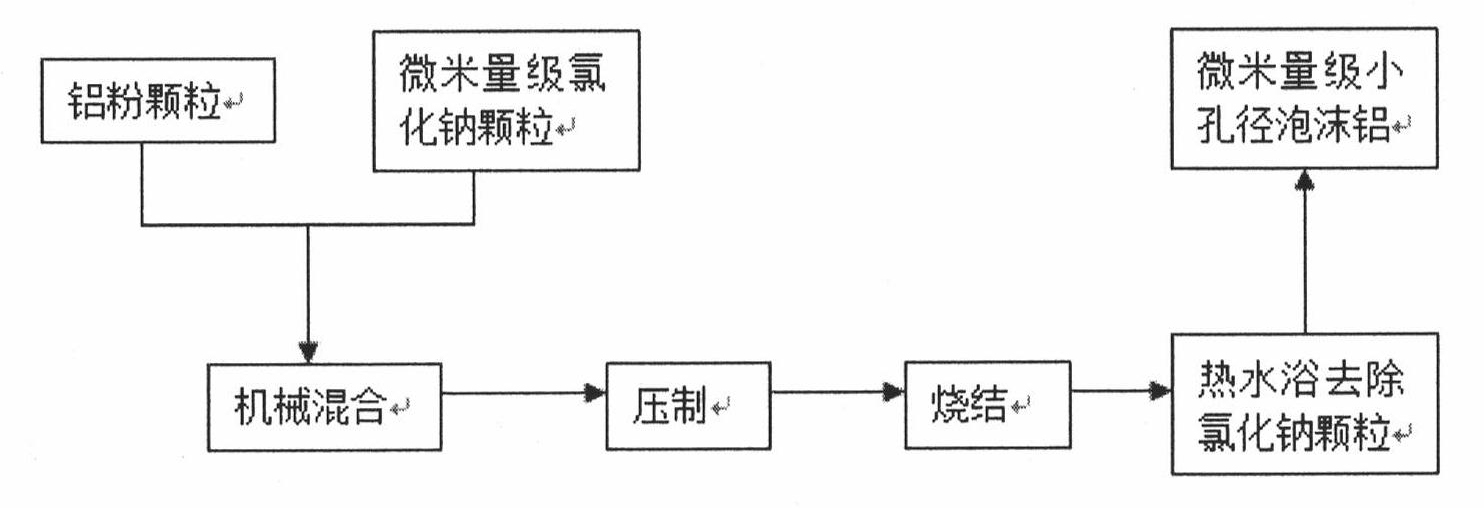

Preparation process of small-aperture foamed aluminum with strictly controllable void ratio

A preparation process and technology of foamed aluminum, applied in the field of preparation of small-pore aluminum foam, can solve the problems of high cost, complex process, difficult to control the uniformity of pore size distribution, etc., and achieve the effect of saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

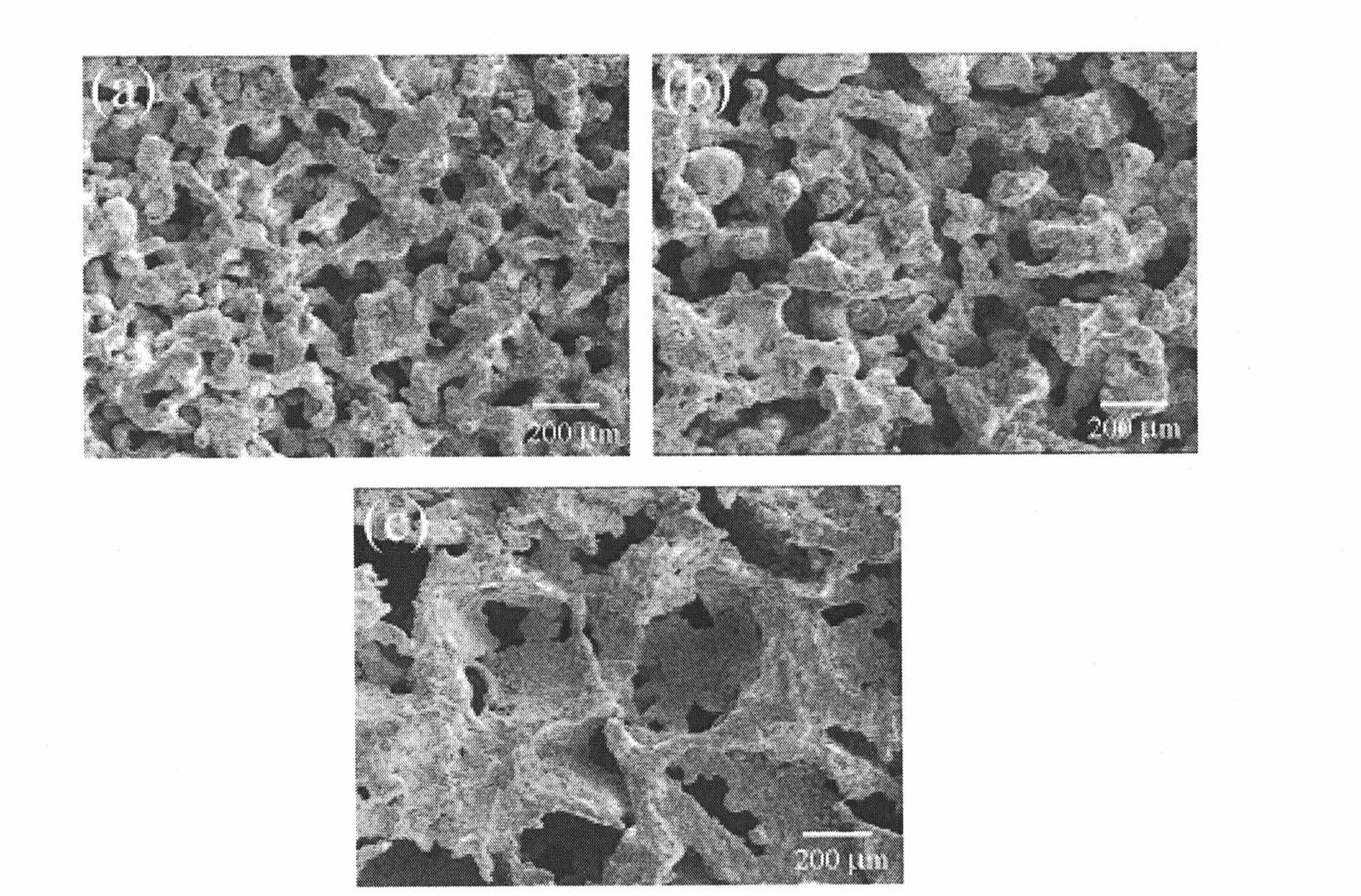

[0021] Embodiment 1: Selecting the commercial aluminum powder with a purity of 99% and a particle size of 30 microns, and industrial sodium chloride with an average particle size of 175 microns, according to the volume requirements of the prepared product, weigh specific quality aluminum powder and chloride Sodium particles, add a small amount of ethanol, mix the three mechanically until uniform, press the mixed powder into a prefabricated block in one direction under a pressure of 260MPa, and then put the prefabricated block into the furnace for sintering at 663°C for 22 hours. Put the sintered briquette into a hot water bath at 95°C and heat for 10 hours to prepare aluminum foam with small pores.

[0022] After detection and analysis, the porosity of the prepared product is 73.2%, the pore size is about 175 microns, the pore size distribution is uniform, and it is a three-dimensional interconnected space network structure.

Embodiment 2

[0023] Embodiment 2: select the commercial aluminum powder that purity is 99%, particle diameter is 30 microns, the average particle diameter is the industrial sodium chloride of 325 microns, according to the volume requirement of preparation product, take the aluminum powder of specific quality and chloride Sodium granules, add a small amount of acetone, and mix the three mechanically until they are uniform. Press the mixed powder into a prefabricated block in one direction under a pressure of 250MPa, and then put the prefabricated block into a furnace for sintering at 660°C for 20 hours. Put the sintered briquette into a hot water bath at 95°C and heat for 10 hours to prepare aluminum foam with small pores.

[0024] After detection and analysis, the porosity of the prepared product is 64.8%, the pore size is about 325 microns, the pore size distribution is uniform, and it is a three-dimensional interconnected space network structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com