Universal knife sharpener

A kind of knife sharpening machine, a universal technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems that affect the accuracy of knife grinding, the performance is particularly obvious, and the structure of the driving mechanism is complex, so as to achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

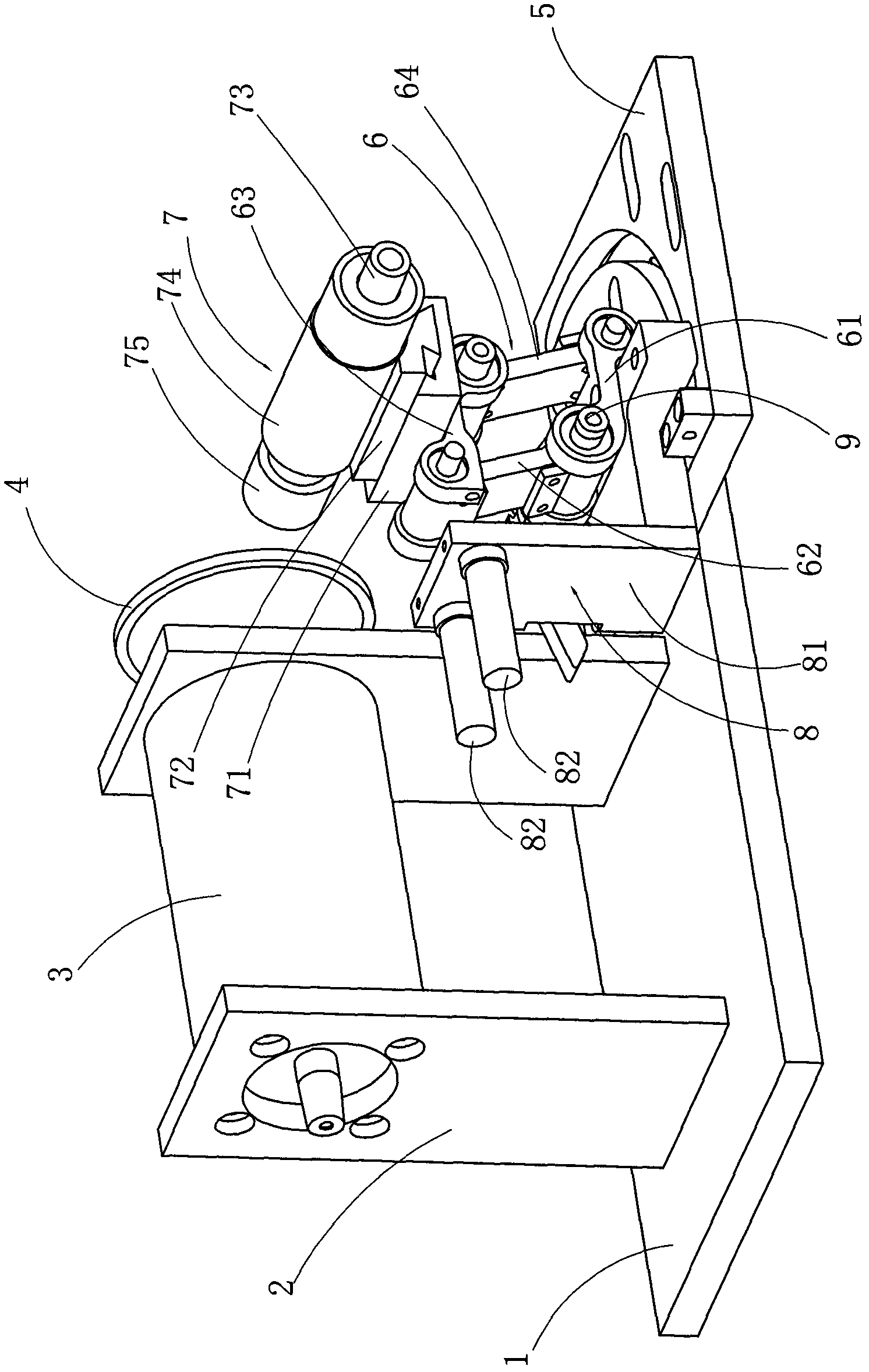

[0020] Such as figure 1 and 2 The universal knife grinder includes a motor base 1, a motor support 2 is fixed on the motor base 1, a motor 3 is fixed on the motor support 2, an output shaft of the motor 3 is connected to a grinding wheel 4, and a knife rest is fixed on the motor base 1 The base 5 and the knife rest base 5 are fixed with a support frame 6 , on which a knife rest holder 7 for fixing a knife is arranged, and a collision mechanism 8 is provided on one side of the support frame 6 .

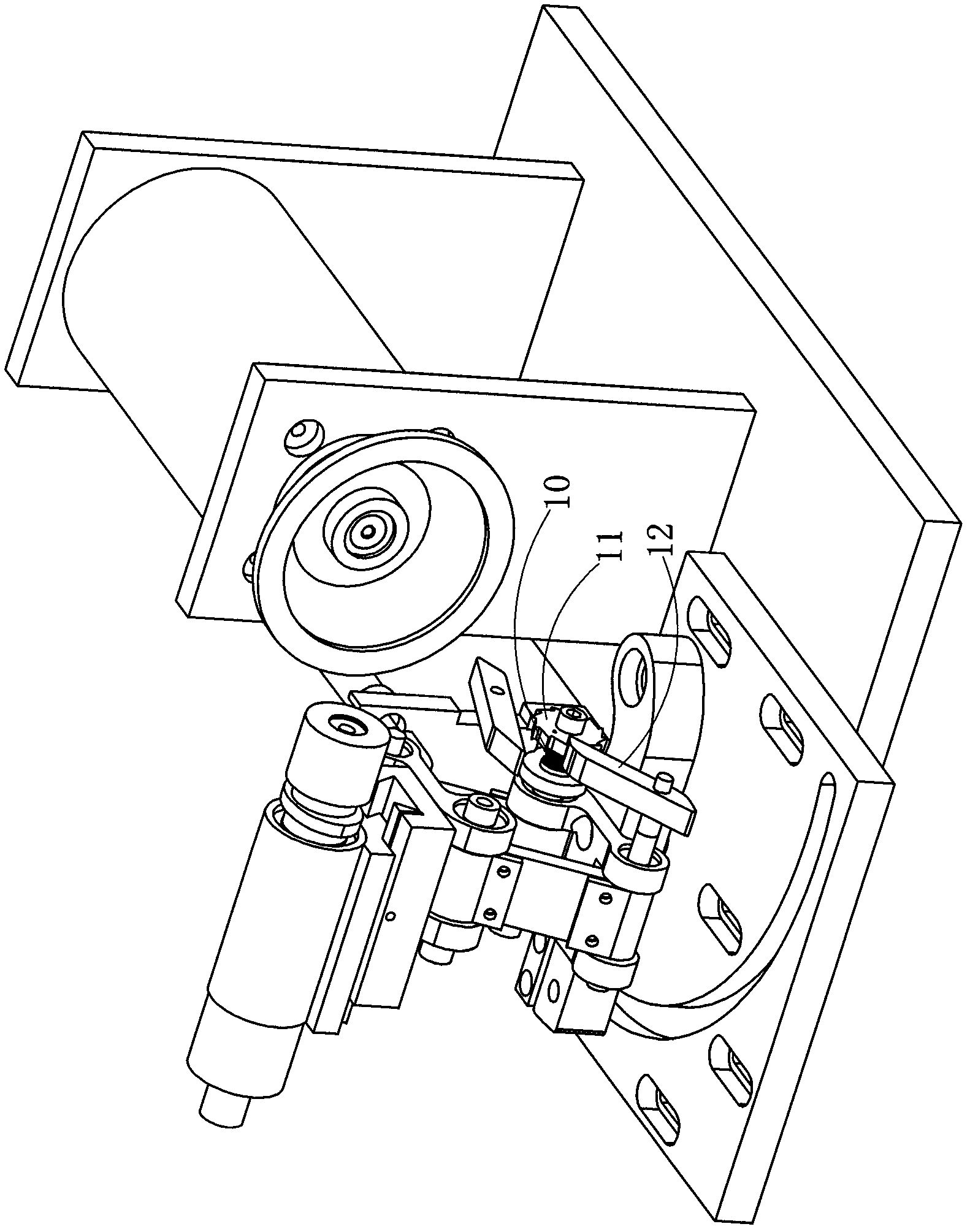

[0021] In this embodiment, the support frame 6 includes four connecting arms 61, 62, 63, 64 connected end to end to form a quadrilateral bracket, and one connecting arm 61 located at the bottom of the four connecting arms is rotatably fixed on the tool holder through a shaft. On the base 5, and the connecting parts where the four connecting arms are connected end to end are connected through the rotation of the chain rod 9; The connecting arm 62 pushes towards the torsion spring 10 o...

Embodiment 2

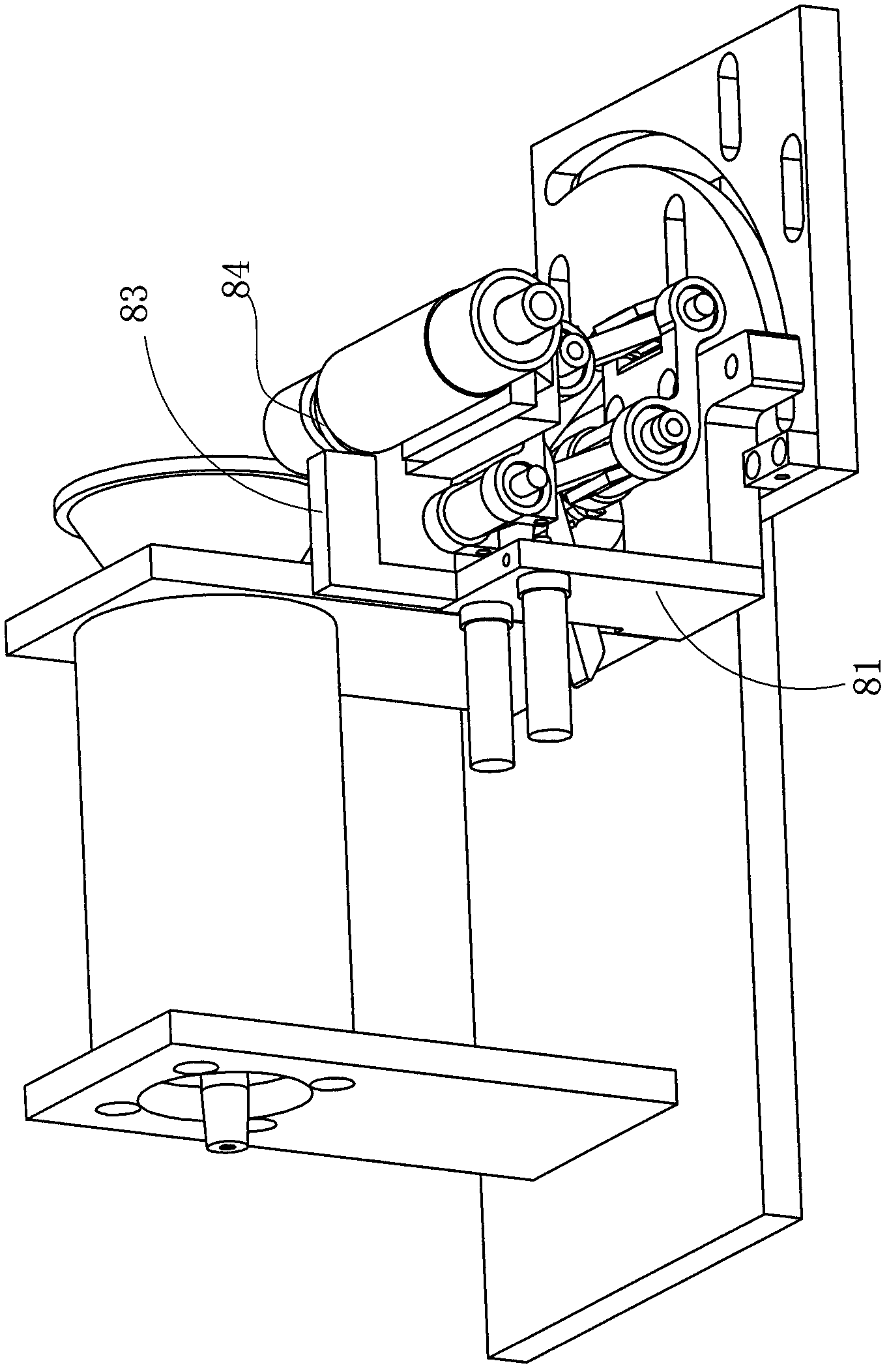

[0025] Different from the first implementation, the fixed bracket 81 is detachably provided with an L-shaped auxiliary arm 83 for grinding special-shaped knives, and the first end of the first arm in the L-shaped auxiliary arm is detachably plugged and fixed on the On the fixed bracket 81, the second end of the first support arm is connected to the first end of the second support arm, and the second end of the second support arm is connected to the cross-section of the tool rest holder 7 that is sleeved on the rotating shaft. The control sleeve 84 is a corresponding interference fit.

Embodiment 3

[0027] The difference from Embodiment 1 is that the support frame 6 includes a guide rail 65 fixed on the base of the tool holder, and a slider 66 arranged on the guide rail is moved, and the lower end of the slider is provided with a device capable of accommodating the guide rail. rail groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com