Processing method and die for shaft sleeve used for automobile steering transmission mechanism

A technology of steering transmission and processing methods, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of wall thickness reduction, high scrap rate, thickening, etc., and achieve the effect of avoiding wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

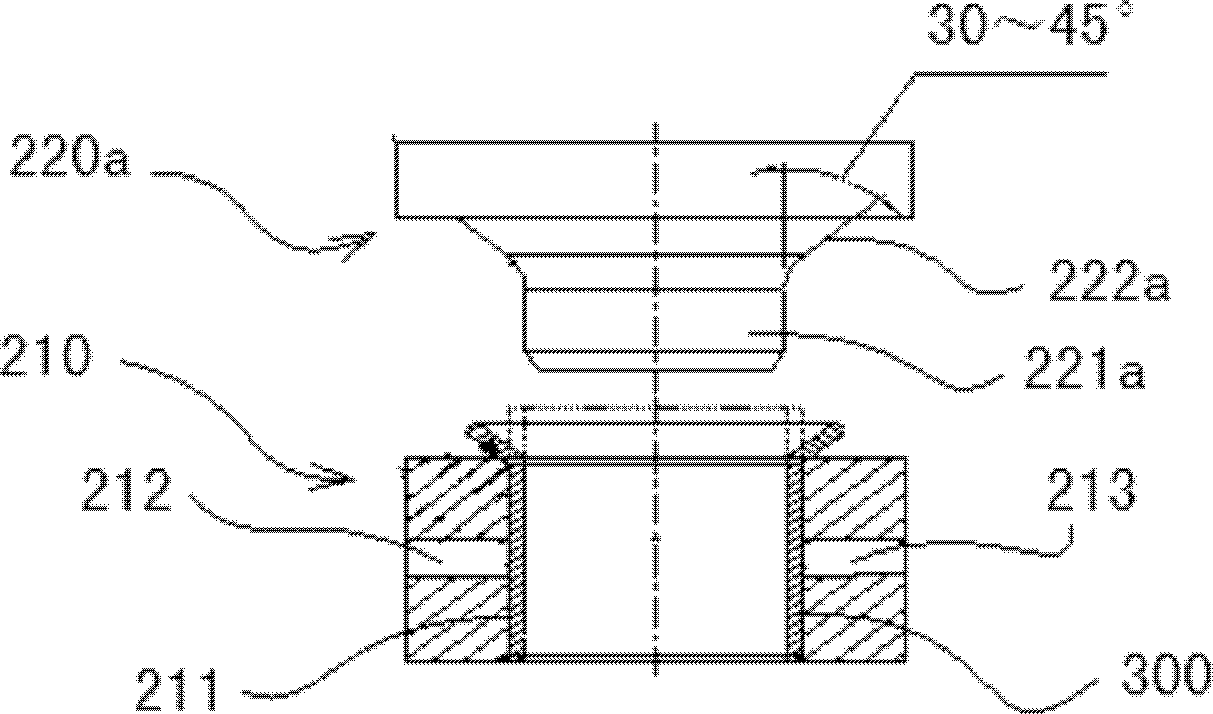

[0020] In order to make the technical means, creative features, goals and effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0021] see figure 2 , the automobile steering transmission mechanism shaft sleeve 100 is a cylindrical part with flanges 110, 120 at both ends, its inner diameter is Φ38_0.2mm, the outer diameter of the flange 110, 120 is Φ53+1.5mm, the flange The angle between sides 110, 120 and the outer cylinder wall is 90°, the wall thickness of the entire cylinder wall is 2.5±0.2mm, and the transition between flange sides 110, 120 and the inner cylinder wall is R3.5±0.3mm. The height of automobile steering transmission mechanism axle sleeve 100 is 40-0.2mm.

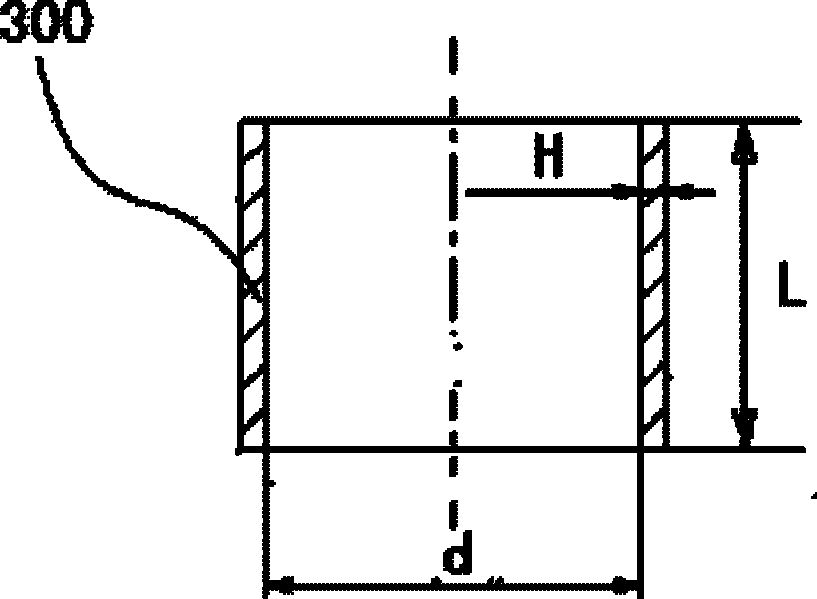

[0022] For this reason, the axle sleeve 100 of this automobile steering transmission mechanism adopts such as figure 1 The shown material is the seamless steel pipe of E235+N as the matrix 300, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com