Separator suitable for removing silt from activated sludge of sewage treatment plant

A technology of activated sludge and separator, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of accelerating equipment wear, affecting the normal operation of sewage treatment plants, affecting the effect of sewage treatment, etc., to improve rotation Angular velocity, beneficial to separation, and the effect of enhancing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

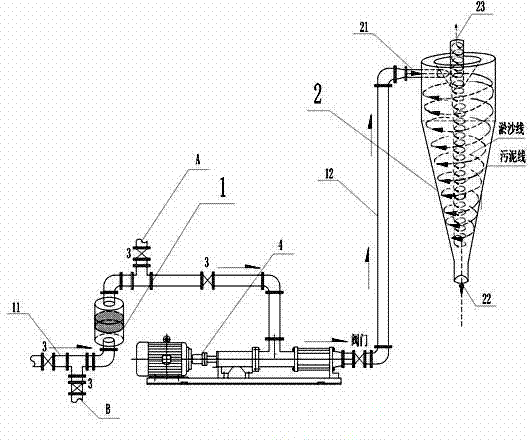

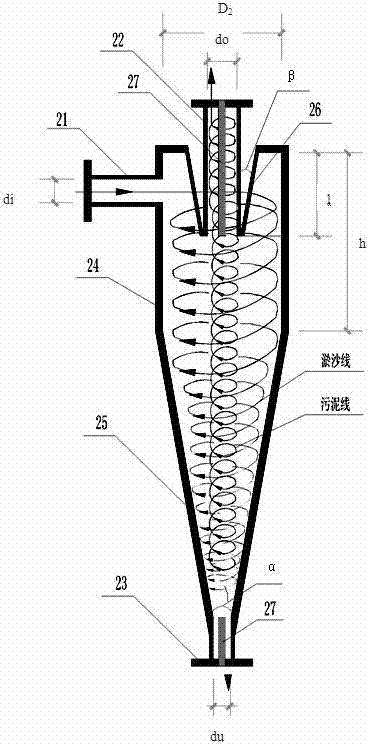

[0031] see figure 1 , This separator is composed of two parts: pretreatment area 1 and core separation area 2. The activated sludge is input from the mud inlet pipe 11 of the pretreatment area, and the mud outlet pipe 12 of the pretreatment area is connected to the feed port 21 of the core separation area through pipelines, and the separated silt is discharged from the bottom outflow sand port 22, and the activated sludge The mud is discharged from the overflow mud outlet 23. A valve 3 and a pump 4 are arranged on the pipeline, a backwash water outlet A is arranged before the pretreatment area 1, and a backwash water inlet B is arranged behind.

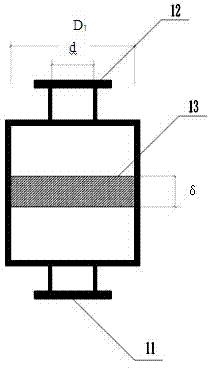

[0032] see figure 2 , the pretreatment 1 is barrel-shaped, and a screen 13 is arranged horizontally inside it to intercept hair, grass blades and large particles in the sludge. 12 is a mud pipe, and 11 is a mud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com