Sulfuryl fluoride application control device for containers

A control device, sulfuryl fluoride technology, applied in the direction of trapping or killing insect devices, applications, fumigators, etc., can solve the problems of human, animal and plant injury, waste of manpower, uneven application amount, etc., and achieve precise control Application amount, increase heat absorption time, uniform and sufficient effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

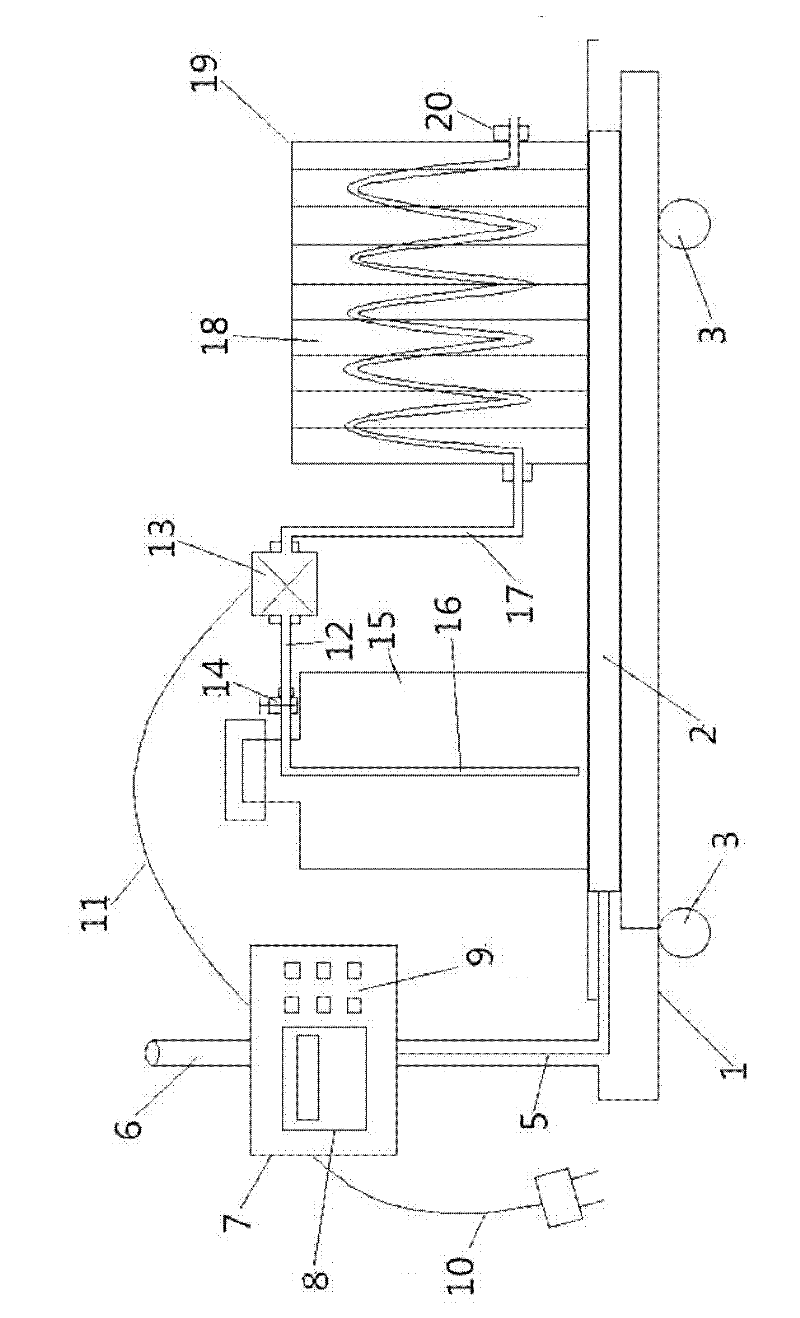

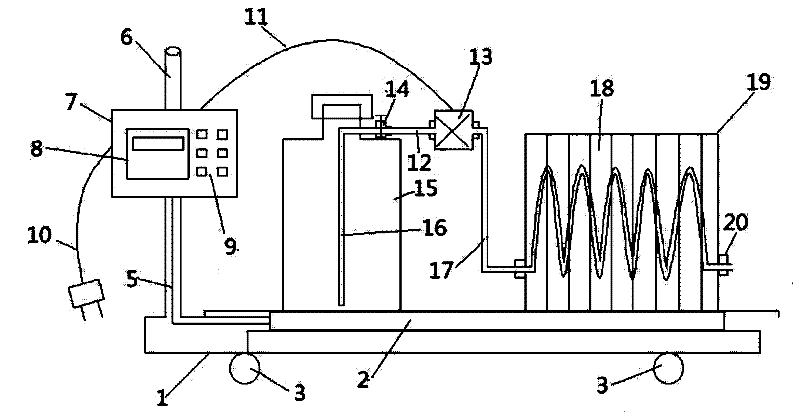

[0024] Such as figure 1 Shown is a schematic structural diagram of an embodiment of a containerized sulfuryl fluoride dosing control device according to the present invention. The containerized sulfuryl fluoride dosing control device in this embodiment includes a dosing device and a control system.

[0025] The drug dispensing device comprises a base 1, a storage bottle 15 placed at the front of the base 1 and a heat absorber 19 placed at the rear of the base, and a pressure sensor 2 is also arranged between the storage bottle 15 and the base 1, and the storage bottle 15 passes through the The pressure sensor 2 is placed on the base 1 . The storage bottle 15 and the heat absorber 19 are connected by a connecting conduit 17, an electromagnetic valve 13 is arranged on the connecting conduit 17 between the switch 14 of the storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com