How to regenerate the filter

A filter and process technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc., can solve problems such as the reduction of the purity of purified acrylic acid, and achieve the effect of preventing deterioration of color tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

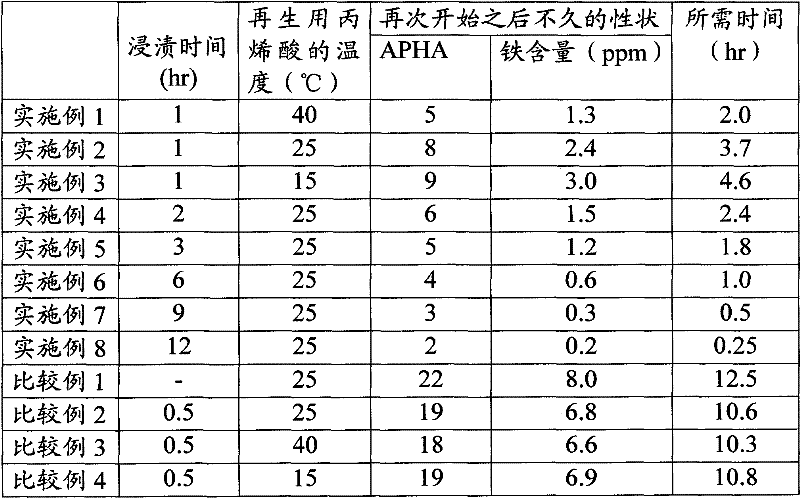

Examples

Embodiment 1

[0055] 1) Drain the acrylic acid remaining in the case. This acrylic acid is recovered and recycled to the aforementioned acrylic acid capture step.

[0056] 2) Water is supplied into the case to wash the filter with water. That is, the continuous operation of draining the water immediately after filling the casing with water was repeated until the pH of the washed water became 6.5. A part of the early washed water is recovered and recycled to the above-mentioned acrylic acid capture step, and the remaining washed water is removed outside the system.

[0057] 3) A 10% by mass sodium hydroxide aqueous solution was supplied into the case to perform alkaline washing of the filter. Alkaline washing is performed as follows. That is, the casing was filled with an aqueous sodium hydroxide solution, and the aqueous sodium hydroxide solution was circulated in the casing by a pump for a while, and then discharged from the casing. This operation was repeated 3 times. The alkaline aq...

Embodiment 2

[0062] In the said process 5), it carried out by the method similar to Example 1 except having set the temperature of the acrylic acid for regeneration to 25 degreeC.

Embodiment 3

[0064] In the said process 5), it carried out by the method similar to Example 1 except having set the temperature of the acrylic acid for regeneration to 15 degreeC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com