A motion trajectory planning method in the operating space of a heavy-duty industrial robot

An industrial robot and operating space technology, applied in the direction of instruments, non-electric variable control, position/direction control, etc., can solve the problem of not realizing the smoothness of motion commands, not realizing the best compromise between optimal time and energy consumption, and space Problems such as discontinuous acceleration at the start point and end point of the multi-point spline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

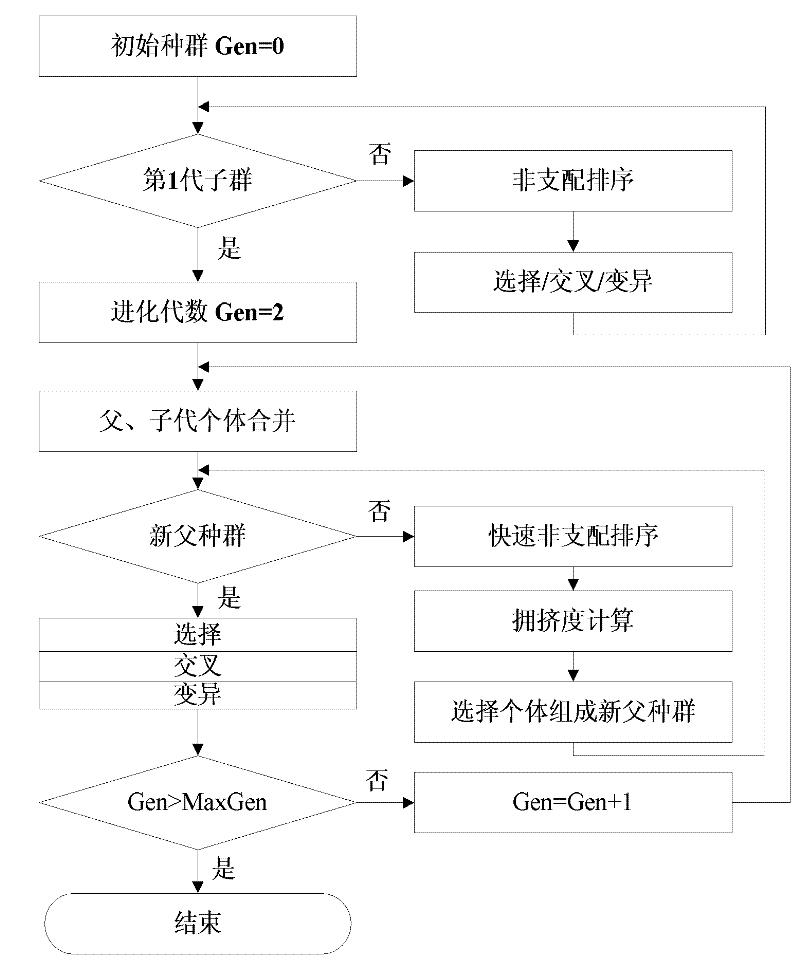

[0052] Embodiment 1: The specific process of the motion trajectory planning method in the operation space of a heavy-duty industrial robot described in this embodiment is as follows:

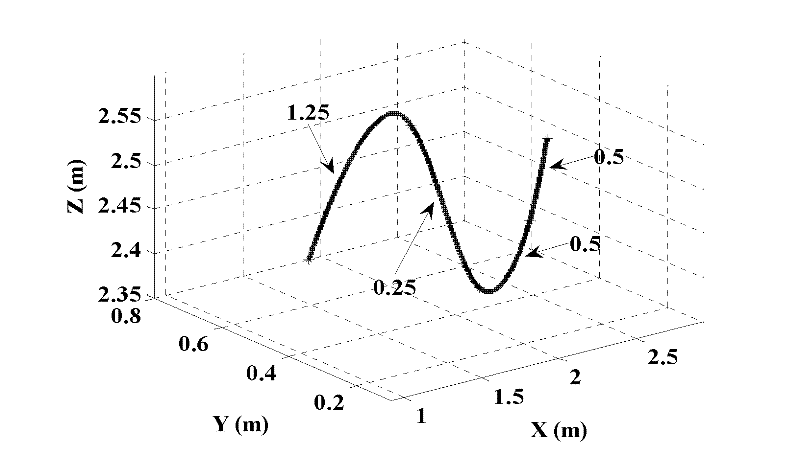

[0053] Step A. Use the modified spline function to interpolate for multiple points in the space:

[0054] Step A1: Use a cubic spline curve to establish a basic interpolation function, and use a cubic polynomial to interpolate between any two preset points. The expression of the basic interpolation function is as follows:

[0055] S j (t)=a j +b j (t-t j )+c j (t-t j ) 2 +d j (t-t j ) 3

[0056] t∈[t j , t j+1 ], j=0, 1, ..., n-2 (1)

[0057] The time interval between two adjacent preset points is h j =t j+1 -t j ; a j , b j , c j , d j is the coefficient to be determined; n represents the number of preset points;

[0058] Step A2: At the same time, the function value S must be guaranteed at each preset point to ensure continuity j The first derivative value S′ of (t) j (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com