Metal packaged fiber Bragg grating sensor and manufacturing method thereof

A technology of fiber optic Bragg and grating sensors, which is applied in the direction of using optical devices to transmit sensing components, measuring device casings, etc., can solve the problems of not being able to improve the strain sensitivity coefficient, and achieve the effects of wide application range, low cost, and strong protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0054] Bond the fiber grating to the thin metal tube with glue, and put a metal base on both ends of the metal tube. There are solder spots on the metal base for welding with the object to be measured. The specific steps and parameters are as follows:

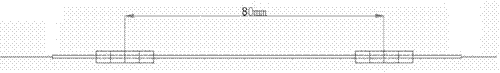

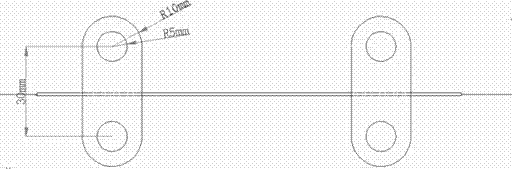

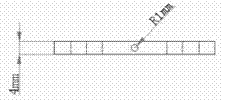

[0055] Such as figure 1 For the stainless steel pipe shown, the inner diameter is 0.7mm, the outer diameter is 1.0mm, and the length is 80mm (it can be changed appropriately to ensure that the grating part can be completely covered by the steel pipe). We choose 1:3 AB glue to bond the fiber grating and the metal pipe, and The combination between metal pipe and metal base. Such as figure 2 , image 3 The metal base shown, select the size parameters: thickness 4mm, length 30mm, semicircle diameter 10mm, welding hole diameter 5mm, steel pipe hole 1mm. The packaging environment is packaged at room temperature and normal pressure of 16.7°.

[0056] Steps:

[0057] Pass the fiber grating through the steel pipe, straighten the ...

example 2

[0059] Bond the fiber grating to the thin metal tube with glue, and put a metal base on both ends of the metal tube. There are solder spots on the metal base for welding with the object to be measured. The specific steps and parameters are as follows:

[0060] Stainless steel pipe, inner diameter 0.3mm, outer diameter 0.6mm, length 70mm (can be changed appropriately to ensure that the engraved grating part can be completely covered by the steel pipe). We choose 1:2 AB glue for bonding fiber gratings and metal pipes, as well as metal pipes. The bond between the tube and the metal base. Metal base, select size parameters: thickness 5mm, length 50mm, semicircle diameter 10mm, welding hole diameter 5mm, steel pipe hole 1mm, the specific operation steps are as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com