Prestressed anti-fatigue steel beams

A prestressed steel strand and prestressed technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of major accidents, sudden accidents, low material strength utilization, etc., and achieve the effect of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

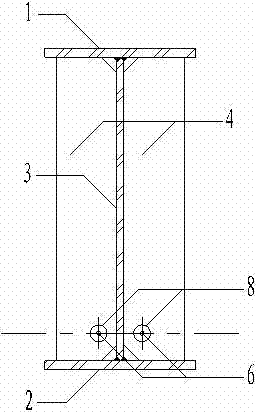

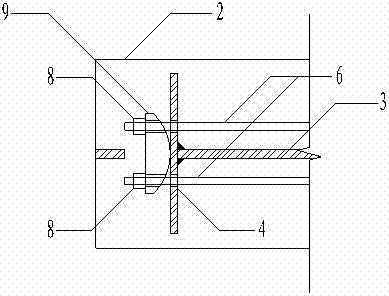

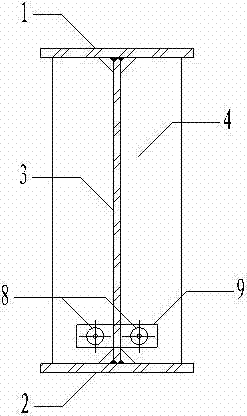

[0024] Embodiment 1: as Figure 1-Figure 6 As shown, the device consists of upper flange 1, lower flange 2, web 3, support stiffening plate and prestressed anchor plate 4, anchor hole 5, high-strength prestressed steel strand 6, anchor stiffening plate 7, anchor Head 8, curved plate 9, support steel corbel 10 and anti-sideshift pad 11 are formed. The upper flange 1, the lower flange 2 and the web 3 form a welded H-shaped steel beam. Both ends of the H-shaped steel beam are fixed on the support steel corbel 10, and anchor plates 4 are welded on both sides of the web 3 above the support steel corbel 10. The anchor plate 4 is used both as a steel beam support stiffening plate and also as a prestressed anchor plate. One end (right end) of the H-shaped steel beam is provided with anchor holes 5 on both sides symmetrical to the web 3 at the anchor plate 4 near the lower flange, and anchor holes 5 are welded with anchorage area stiffeners 7 up and down. Beam other end (left end) i...

Embodiment 2

[0026] Embodiment 2: The device described in Embodiment 1 is used for the box-shaped steel girder of the bridge crane, and the prestressed steel strands 6 are arranged on both sides of the web 3 near the tension flange of the box-shaped steel beam of the bridge crane, and the It applies a pretension. Similarly, after deducting the loss of prestress, the pretension produces compressive stress on the tension flange. The steel beam is not stretched under fatigue, and the fatigue resistance is satisfactory. Due to the use of high-strength materials and improved material utilization, the weight of the box girder can be greatly reduced, which is beneficial to the reduction of long-term energy consumption of the bridge crane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com