Early-warning method of pitting on strip steel surface in annealing unit

A pitting and strip steel technology, which is applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as increased production costs, prolonging the production cycle of units, and increasing user complaints, so as to prevent broken strips and suppress the occurrence of pitting , Improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention provides a method for early warning of pitting on the strip steel surface of an annealing unit. When setting the early warning value, in order to accurately reflect the severity of pitting on site, the following factors must be considered, and the specific implementation methods are as follows:

[0029] An early warning method for pitting on the strip steel surface of an annealing unit, which includes

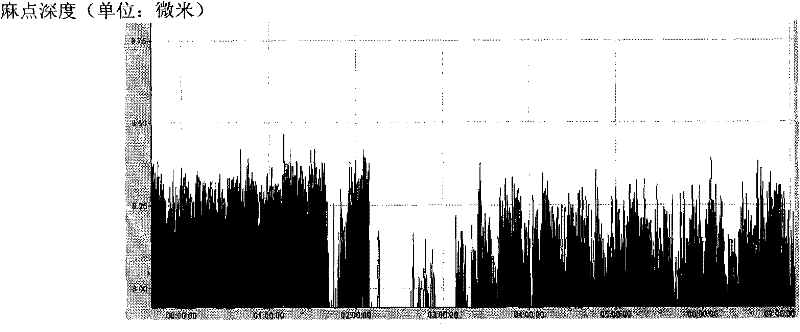

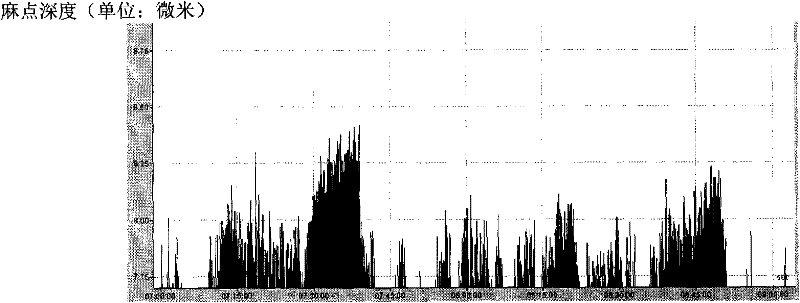

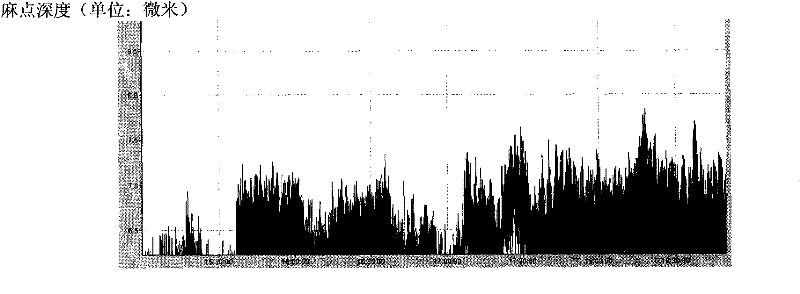

[0030] Step 1, in the SF process section, the strip pitting depth value and the speed difference between the furnace roll and the strip form a linear relationship: an early warning model is established through linear regression, and this relationship can be described by the following formula:

[0031] Pocket depth = a+b×speed difference

[0032] Taking the difference of roll speed in the SF furnace of the cold rolling continuous annealing unit as the input variable, the estimated value of pitting depth is obtained. Among them, a and b are regressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com