A kind of method of producing pyridine compound

A technology of compound and pyridine, which is applied in the field of liquid-phase continuous preparation of pyridine compounds mainly composed of 3-picoline, can solve the problems of easy deactivation of catalysts, and achieve the effects of improving production efficiency, improving utilization rate and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

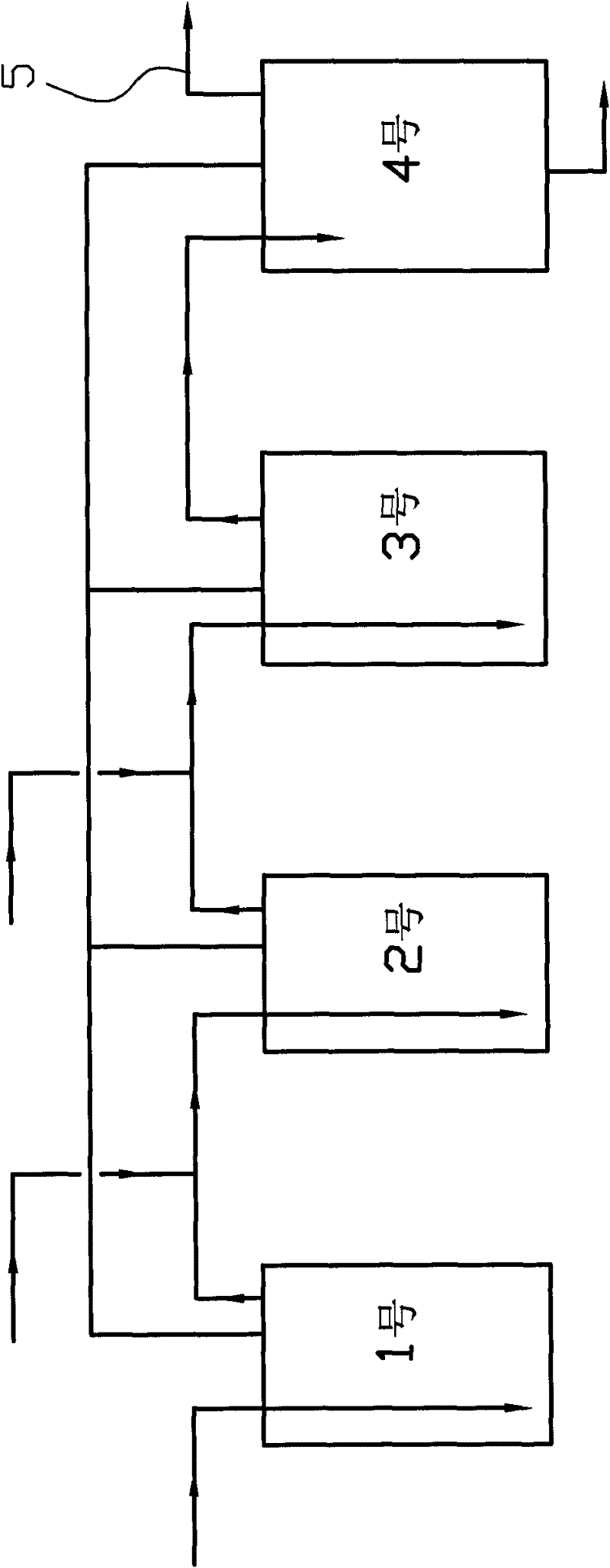

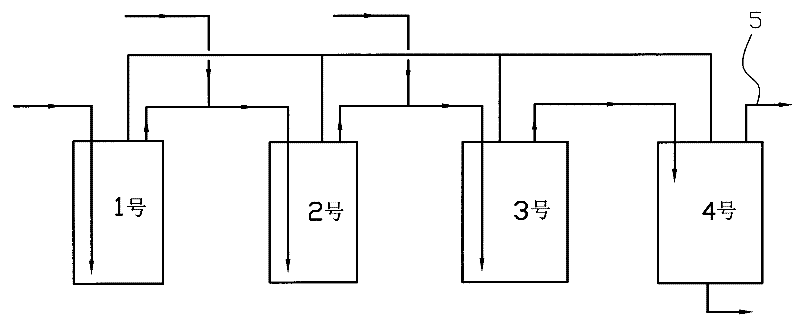

[0022] Four 2L autoclaves are used to form a reactor according to the process flow chart. Add 500 grams of catalyst to the first three autoclaves, respectively add 1200 grams of 50% ethanol aqueous solution to the four autoclaves, start stirring, and heat up to 228 ° C. Turn on the high-pressure metering pumps of No. 1, No. 2, and No. 3 autoclaves, and inject the pre-prepared raw materials (aqueous solution containing 16.3% urotropine, 32% paraldehyde, and 31% ethanol) into the first three autoclaves respectively. Inside, the control pressure is 4.0Mpa. The flow rates are 400 g / h, 350 g / h, and 300 g / h respectively, and the No. 4 autoclave keeps the liquid level stable. Continuous feed 300 hours, obtain altogether 48.99 kilograms of 3-methylpyridines, 1.06 kilograms of pyridines, 2.25 kilograms of 2,5-lutidines, 2.52 kilograms of 3,5-lutidines, 6.63 kilograms of 3-ethylpyridines, 0.8 kg of 2-methyl-5-ethylpyridine.

Embodiment 2

[0024] Four 2L autoclaves are used to form a reactor according to the process flow chart. Add 500 grams of catalyst to the first three autoclaves, respectively add 1200 grams of 50% ethanol aqueous solution to the four autoclaves, start stirring, and heat up to 232 ° C. Turn on the high-pressure metering pumps of No. 1, No. 2, and No. 3 autoclaves, and inject the pre-prepared raw materials (aqueous solution containing 16.3% urotropine, 32% paraldehyde, and 31% ethanol) into the first three autoclaves respectively. Inside. The flow rate is 500 g / h, 450 g / h, 400 g / h respectively, the control pressure is 4.3Mpa, and the No. 4 autoclave keeps the liquid level stable. Continuous feed 300 hours, obtain altogether 54.54 kilograms of 3-methylpyridines, 1.18 kilograms of pyridines, 2.51 kilograms of 2,5-lutidines, 2.83 kilograms of 3,5-lutidines, 7.38 kilograms of 3-ethylpyridines, 0.89 kg of 2-methyl-5-ethylpyridine.

Embodiment 3

[0026] Four 2L autoclaves are used to form a reactor according to the process flow chart. Add 500 grams of catalyst to the first three autoclaves, respectively add 1200 grams of 50% ethanol aqueous solution to the four autoclaves, start stirring, and heat up to 220 ° C. Turn on the high-pressure metering pumps of No. 1, No. 2, and No. 3 autoclaves, and inject the pre-prepared raw materials (aqueous solution containing 16.3% urotropine, 32% paraldehyde, and 31% ethanol) into the first three autoclaves respectively. Inside. The flow rate is 400 g / h, 350 g / h, 300 g / h respectively, the control pressure is 3.6Mpa, and the No. 4 autoclave keeps the liquid level stable. Continuous feed 300 hours, obtain altogether 41.39 kilograms of 3-methylpyridines, 0.95 kilograms of pyridines, 1.98 kilograms of 2,5-lutidines, 2.12 kilograms of 3,5-lutidines, 6.01 kilograms of 3-ethylpyridines, 0.71 kg of 2-methyl-5-ethylpyridine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com