1,4-butanediol chemical waste water treatment technology

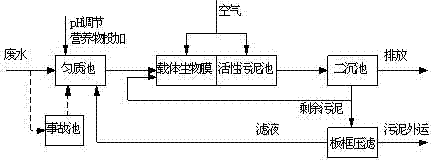

A chemical wastewater and treatment process technology, applied in the field of environmental engineering, can solve problems affecting continuous production, achieve stable operation performance, improve effective microbial sludge concentration and biological treatment performance, and reduce investment and operation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The 1,4-butanediol chemical wastewater first enters the homogeneous distribution tank. The wastewater from the distribution pool is input into the first section of aerobic biological carrier fluidized bed reaction pool + the second section of activated sludge biological oxidation pool + sedimentation tank through the lifting pump, and the volume of the reaction pool is 26L. The outlet flow rate of the wastewater in the homogenization tank is 5L / d, and the COD is 20,231mg / L. Nutrients urea and sodium dihydrogen phosphate are added to the homogenization tank to adjust; and the pH value of the homogenization tank is adjusted to 7. The first section of aerobic biological carrier fluidized bed reaction tank biological carrier (Boride (Nanjing) Purification Technology Co., Ltd. composite modified carrier P15 type) is added 50%, the concentration of microbial sludge in the first section is 10g / L, DO3.5mg / L, hydraulic The stay time is 5 days. The second-stage activated sludge ...

Embodiment 2

[0028] The 1,4-butanediol chemical wastewater first enters the homogenization pool. The wastewater from the homogeneous tank is input into a section of carrier biofilm aerobic tank through the lift pump, and the outlet flow of the wastewater from the homogeneous tank is 60m 3 / d, COD 21,890mg / L, add nutrients urea and disodium hydrogen phosphate to the homogenization pool to adjust, and use alkali to adjust the pH value to 5-7. The first stage of aerobic tank carrier filler (Boride (Nanjing) Purification Technology Co., Ltd. composite modified filler P15 type) added 40%, the first stage of carrier biofilm reaction tank sludge concentration 12g / L, DO2.0mg / L, hydraulic retention The time is 2 days. The second-stage activated sludge tank has a sludge concentration of 4g / L, DO2.5mg / L, and a hydraulic retention time of 3.5 days. The second-stage aerobic effluent enters the secondary settling tank for solid-liquid separation, and the waste water is discharged to the discharge tank...

Embodiment 3

[0031] The 1,4-butanediol process wastewater is first filtered through a grid and then placed in a homogeneous pool. The wastewater from the homogeneous tank is input into a section of carrier biofilm aerobic tank through the lifting pump, and the outlet flow rate of the homogenized tank wastewater is 50m 3 / d, COD 23,538mg / L, add nutrients ammonia water and sodium dihydrogen phosphate to the homogenization pool to adjust; and use inorganic acid or alkali to adjust the pH value of the homogenization pool to 5.0-6.0. The first stage of aerobic tank carrier filler (Boride (Nanjing) Purification Technology Co., Ltd. composite modified filler P15 type) is added with 65%, the sludge concentration of the first stage of carrier biofilm reaction tank is 9g / L, DO3.0mg / L, hydraulic retention The time is 5 days. The second-stage activated sludge tank has a sludge concentration of 3g / L, DO4.0mg / L, and a hydraulic retention time of 5 days. The second-stage aerobic effluent enters the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com