A dual-motor dual-energy hybrid drive system

A drive system, dual-energy technology, applied in electric braking systems, electric vehicles, control drives, etc., can solve the problems of reduced reliability of the whole vehicle drive system, increased cost of the drive motor, and larger motor volume, and can overcome the problem of The effect of dynamic feedback energy absorption is low, charging and discharging power is high, and efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

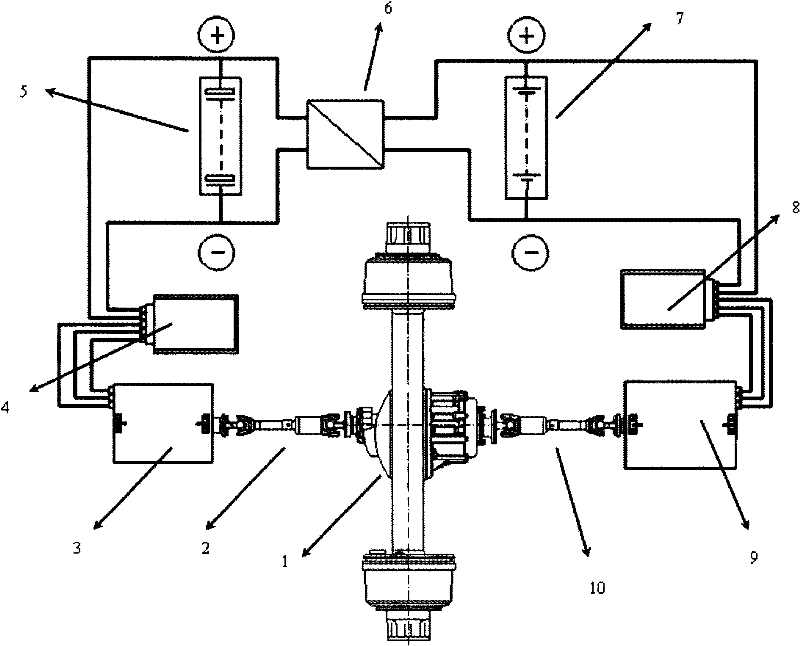

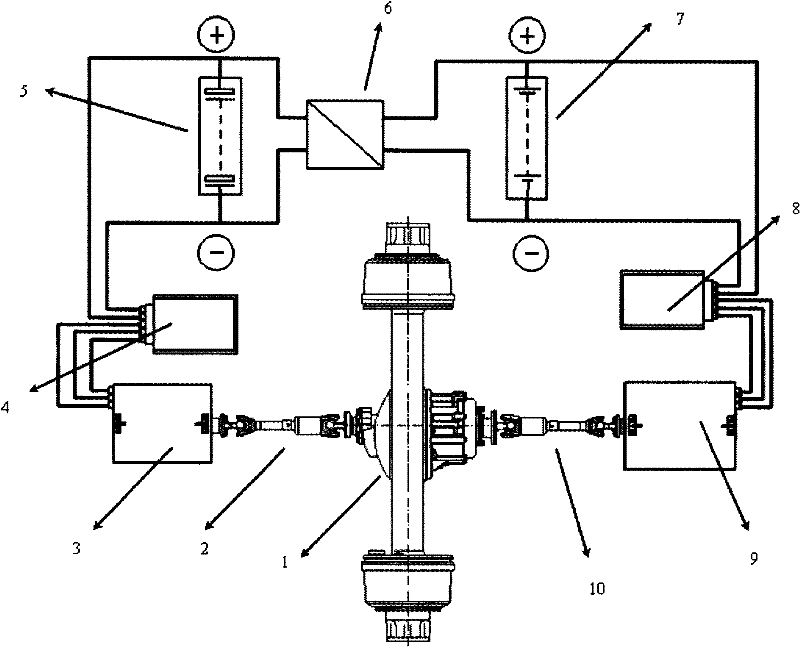

[0011] Embodiments of the invention will be further described with reference to the accompanying drawings.

[0012] The composite drive system architecture proposed by the present invention adopts dual drive motors and power battery-super capacitor dual energy sources, including (7) power battery pack, (5) super capacitor pack, (6) DC / DC converter, (9) main drive motor, (8) main drive motor controller, (3) auxiliary drive motor, (4) auxiliary drive motor controller, (2) auxiliary drive shaft, (10) main drive shaft, (1) double input coupled drive axle, and Control units not listed in the drawings, such as vehicle controller, supercapacitor management system, and power battery management system. The connection relationship is as follows: (6) the input end of the DC / DC converter is connected with (7) the power battery pack, and the output end is connected with (5) the supercapacitor pack. When the supercapacitor management system detects (5) that the power stored in the supercap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com