Bonding method and equipment for metal casing and plastic parts

A technology of metal casing and bonding method, which is applied in the field of bonding metal casing and plastic parts and equipment, can solve problems such as metal casing deformation, achieve the effect of solving thermal expansion deformation, simple operation, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

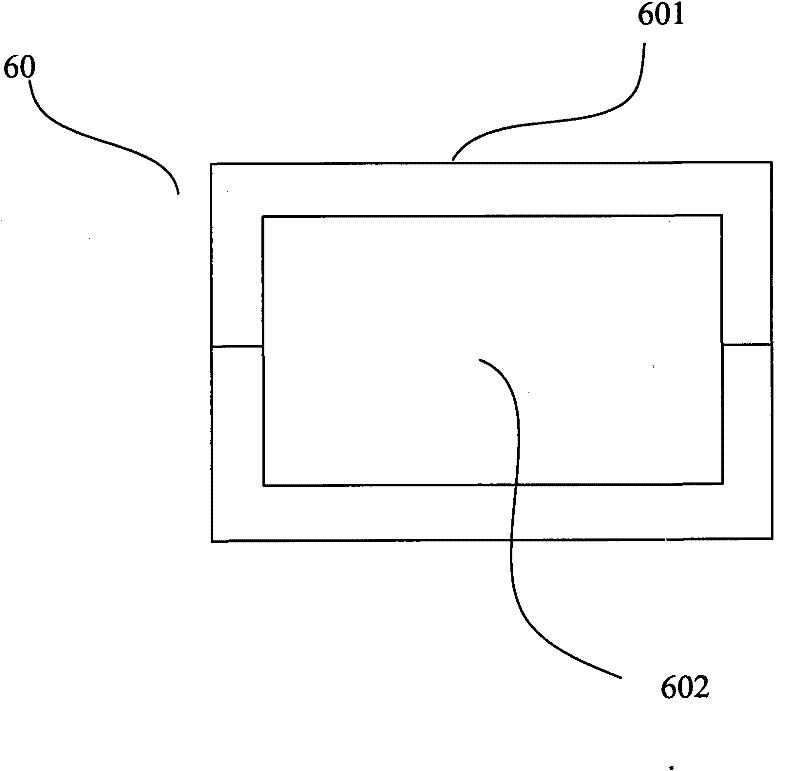

[0036] The size of the metal shell involved in the present invention is (length 344×width 214 millimeters), without reinforcement inside, and the middle part is designed with (105×8×0.2 millimeters) LOGO ABC.

[0037] 1) Put the metal shell on the pre-pressing machine for pre-pressing, set the pre-pressing pressure to 0.3Mpa, the temperature to 80°C, and the pre-pressing time to 7S. The hot melt adhesive is 3M 725.

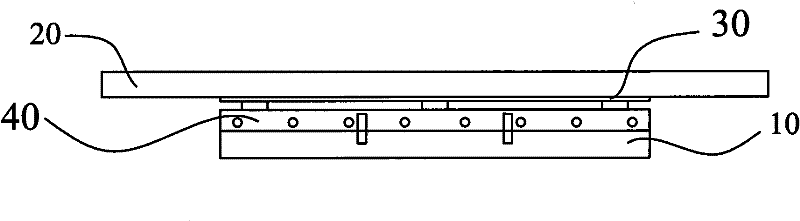

[0038] 2) Hot pressing, after placing the plastic parts and the metal shell on the lower mold, fix the metal shell on the lower mold with locks, pressure plates and side pressure strips, and heat press it with the hot pressing upper mold. The hot pressing pressure is 0.3Mpa, the temperature is 150°C, the hot pressing time is 18S, and the cooling water temperature is 25°C.

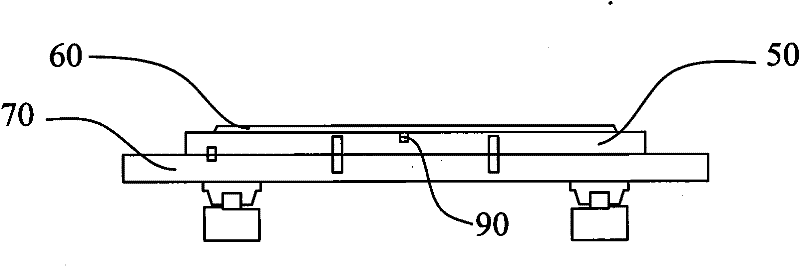

[0039] 3) Cold pressing, move the hot-pressed lower die directly below the cold-pressing upper die, and cold-press it with the cold-pressing upper die. The cold pressing pressure is 0.4Mpa, t...

Embodiment 2

[0042] The size of the metal shell involved in the present invention is (length 344×width 214 millimeters), and there is no reinforcement inside.

[0043] 1) Put the metal shell on the pre-pressing machine for pre-pressing, set the pre-pressing temperature to 80°C, and the pre-pressing time to 7S. The hot melt adhesive is 3M 725.

[0044] 2) Hot pressing, after placing the plastic parts and the metal shell on the lower mold, fix the metal shell on the lower mold with locks, pressure plates and side pressure strips, and heat press it with the hot pressing upper mold. The hot pressing pressure is 0.4Mpa, the temperature is 140°C, the hot pressing time is 10S, and the cooling water temperature is 30°C.

[0045] 3) Cold pressing, move the hot-pressed lower die directly below the cold-pressing upper die, and cold-press it with the cold-pressing upper die. The cold pressing pressure is 0.5Mpa, the temperature is 25°C, the cold pressing time is 10S, and the cooling water temperatur...

Embodiment 3

[0048] The size of the metal shell involved in the present invention is (length 344×width 214 millimeters), without reinforcement inside, and the middle part is designed with (105×8×0.2 millimeters) LOGO ABC.

[0049] 1) Put the metal shell on the pre-pressing machine for pre-pressing, set the pre-pressing temperature to 80°C, and the pre-pressing time to 7S. The hot melt adhesive is 3M 725.

[0050] 2) Hot pressing, after placing the plastic parts and the metal shell on the lower mold, fix the metal shell on the lower mold with locks, pressure plates and side pressure strips, and heat press it with the hot pressing upper mold. The hot pressing pressure is 0.3Mpa, the temperature is 195°C, the hot pressing time is 20S, and the cooling water temperature is 25°C.

[0051] 3) Cold pressing, move the hot-pressed lower die directly below the cold-pressing upper die, and cold-press it with the cold-pressing upper die. The cold pressing pressure is 0.6Mpa, the temperature is 30°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com