A kind of pushable molybdenum electrode cooling water jacket

A cooling water jacket and molybdenum electrode technology, which is applied in electric furnaces, pot furnaces, furnaces, etc., can solve the problems of internal scaling and blockage, cooling water pipeline cracking, etc., and achieve uniform and reliable cooling, long-term stability and high reliability cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

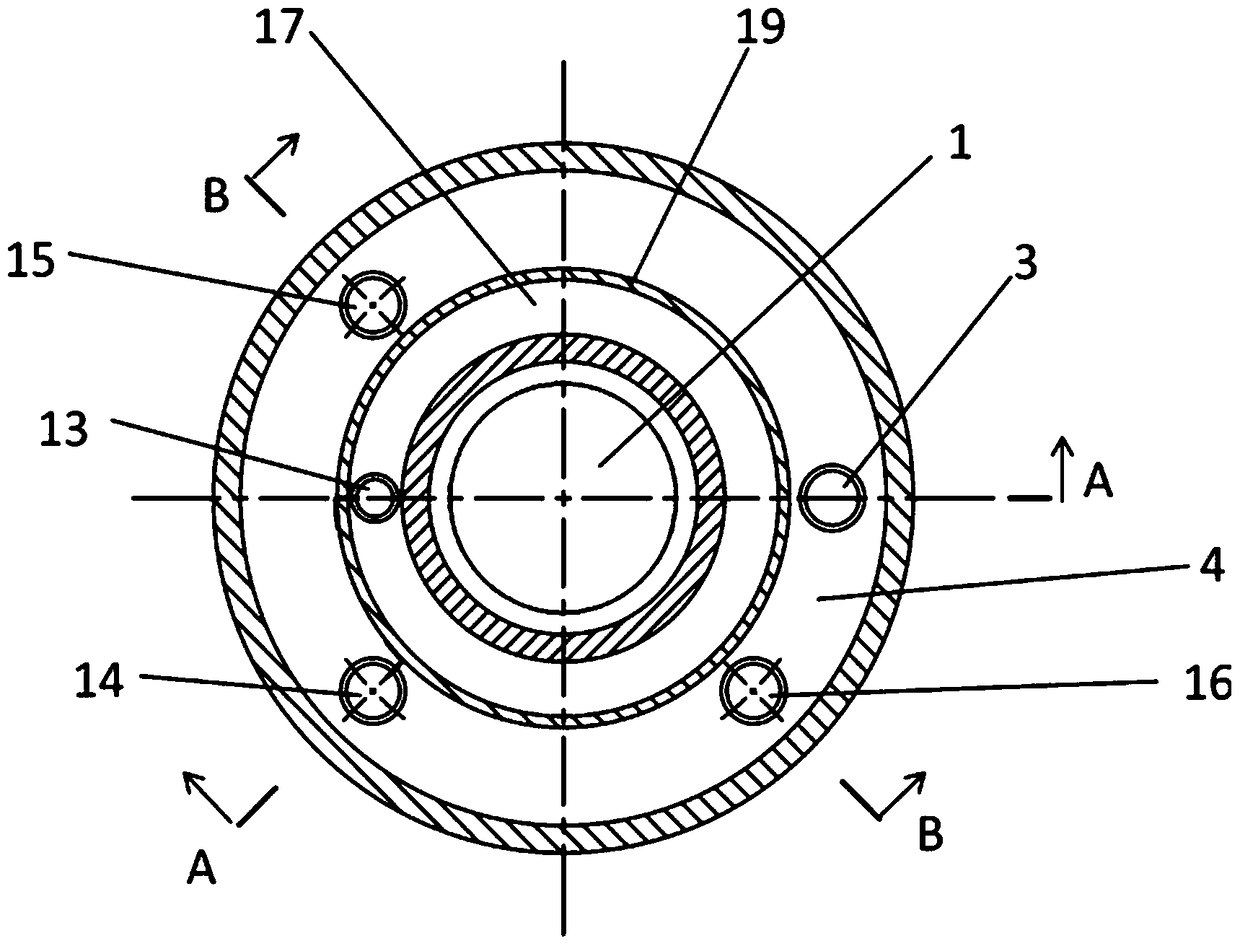

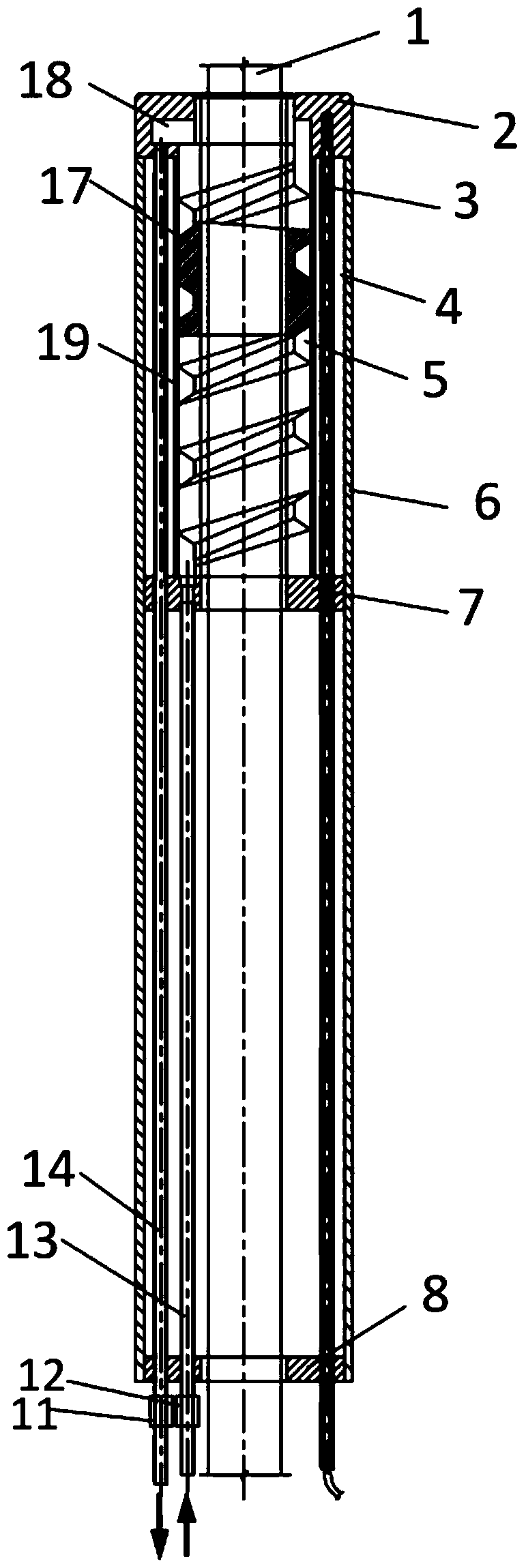

[0073] At the same time, three groups of experiments were carried out to verify the cooling effect of the continuous pushing type molybdenum electrode cooling water jacket of the present invention and the performance of different working modes. Figure 7 to Figure 9 are the structural schematic diagrams of the devices used in the three groups of experiments, which are only used for illustration purposes. Figure 7 The reference molybdenum electrode cooling water jacket used in the first group of experiments but did not draw its internal structure in detail, Figure 8 with Figure 9 The part from the middle plate to the tail plate of the molybdenum electrode cooling water jacket is not drawn.

[0074] The first group uses the molybdenum electrode cooling water jacket (model EH-15-2"-1600) produced by Horn Glass Industries.

[0075]The second group adopts the continuous push-type molybdenum electrode cooling water jacket described in the present invention, and is in the normal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com