Steel belt retractor

A technology of retractor and steel belt, applied in the field of steel belt retractor and unwinder, which can solve the problems of uneven tension in steel belt retraction, inconvenient manual handling, and easy falling off of steel belt, etc., and achieves low cost, simple structure, The effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

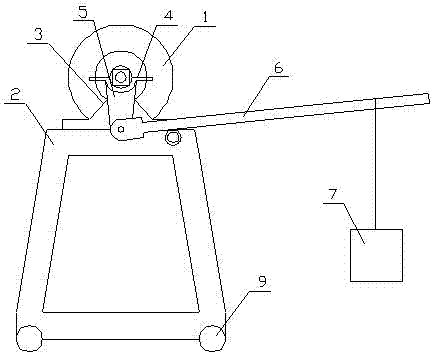

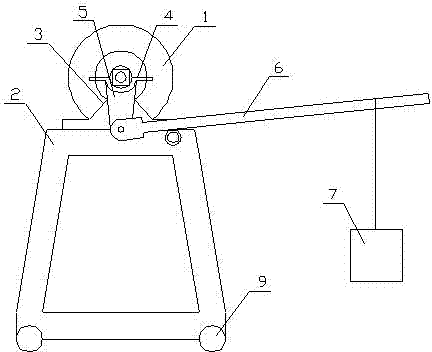

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Example figure 1 , figure 2 As shown, this embodiment provides a steel belt retractor, including a winding shaft 1, a bracket 2 and a brake device 3, the bracket 2 supports both ends of the winding shaft, and is set on the bracket 2 at one end of the winding shaft 1 There is a brake pad device 3, the brake pad device includes a brake pad 4, a brake pad head 5, a brake lever 6 and a weight 7, one end of the brake lever 6 is hingedly connected with the brake pad head 5, the middle part of the brake lever 6 is hingedly connected with the bracket 2, and the other A heavy hammer 7 is hung on one end, and the heavy hammer can adjust the weight. The other end of the brake disc head 5 is provided with a brake disc 4, and the brake disc 6 contacts an end of the winding shaft; four pulleys 9 are set at the bottom of the support 2.

[0014...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com