Preparation method of food dough material and making method of sweet soup balls

A dough and food technology, applied in the field of food dough material preparation, can solve the problems of poor food taste and high processing cost, and achieve the effects of improving taste, reducing processing cost and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

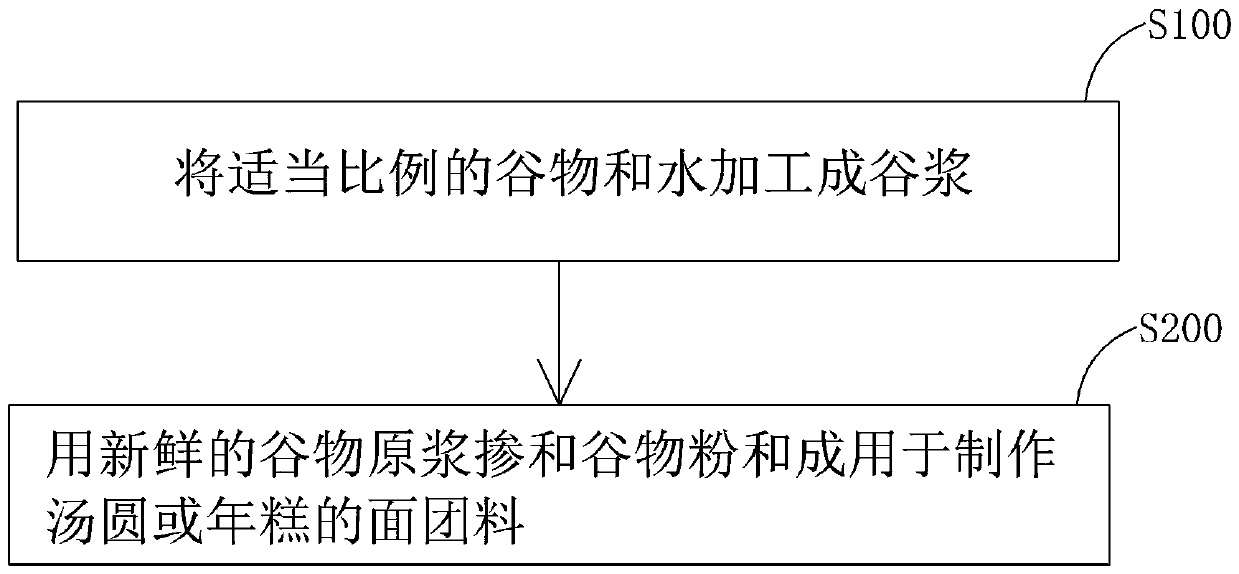

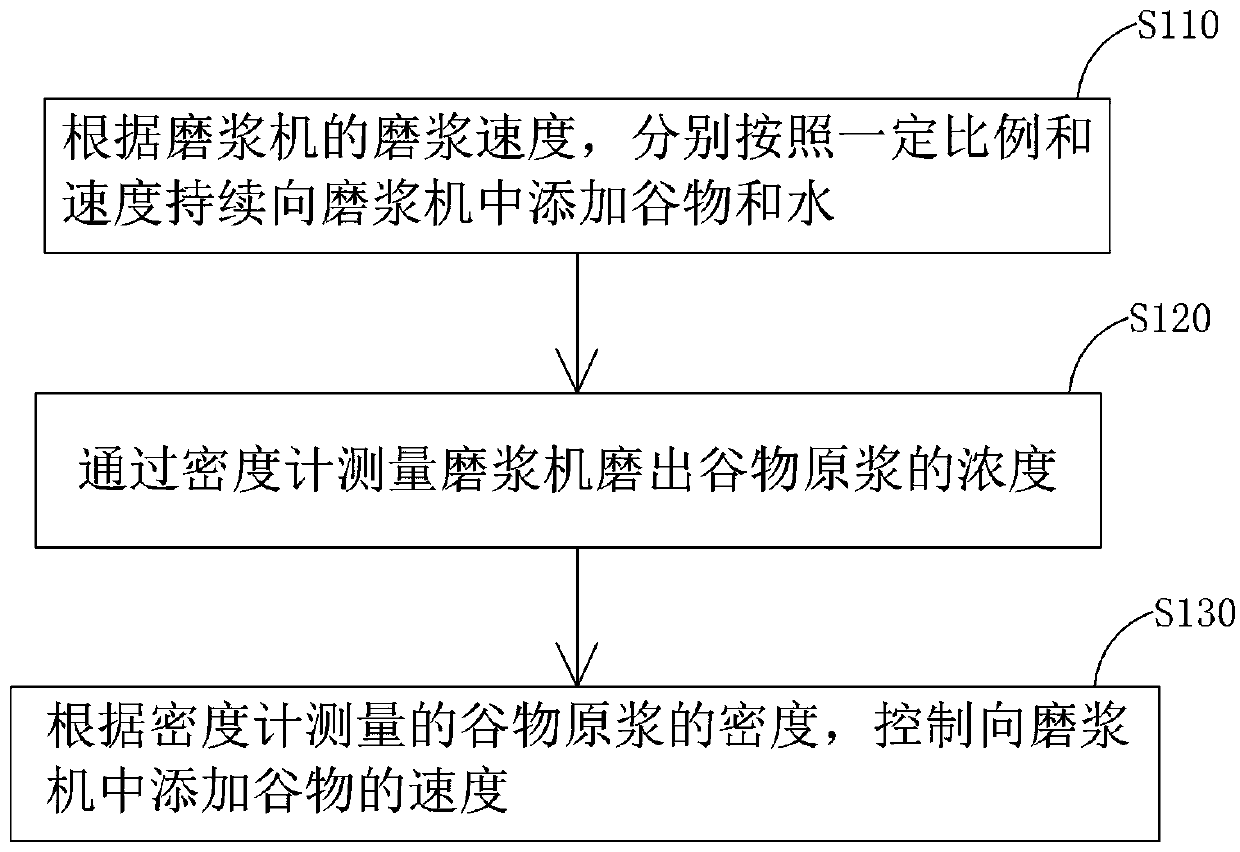

[0042] A preparation method of food dough material, please refer to Figure 1 to Figure 5 .

[0043] The dough material processed by the food dough material preparation method provided in the embodiment of the present invention is used for making glutinous rice balls or rice cakes, such as figure 1 As shown, the method specifically includes the following steps:

[0044] Step S110: Process grains and water in appropriate proportions into grain puree. In this step, the grain is soaked glutinous rice, the ratio of glutinous rice and water is such that the density of the processed glutinous rice puree is 1.2 g / cm³, and the processed glutinous rice puree is fresh raw glutinous rice puree.

[0045] Step S120: Mixing the grain flour with fresh grain puree to form a dough material for making glutinous rice balls or rice cakes. In this step, the grain flour is glutinous rice flour, which is directly kneaded with the glutinous rice flour and fresh raw glutinous rice puree, and finall...

Embodiment 2

[0067] A method for making glutinous rice balls, which uses a glutinous rice ball machine as a processing device, and uses the dough material in Example 1 to wrap sesame paste fillings to make glutinous rice balls. Since the dough material in Example 1 is processed from glutinous rice puree and glutinous rice flour, the aroma of glutinous rice is retained to the greatest extent, so the processed glutinous rice balls have good taste and more nutritional content than those made in the traditional way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com