Arc striking device for electric switch equipment

An arc striking device, electric switch technology, applied in electric switches, high-voltage/high-current switches, circuits, etc., can solve the problem of contact burnout, require high contact resistance to burnout, affect the reliability of switch operation and service life and other issues, to achieve the effect of reducing the degree of burning loss, shortening the burning time, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

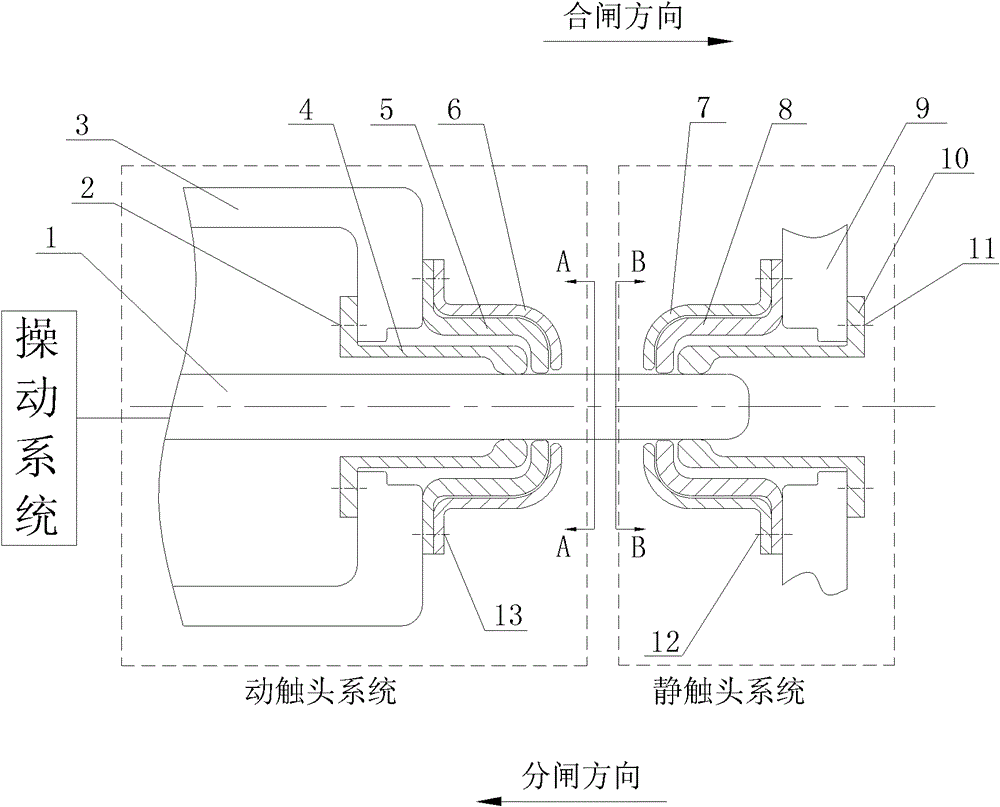

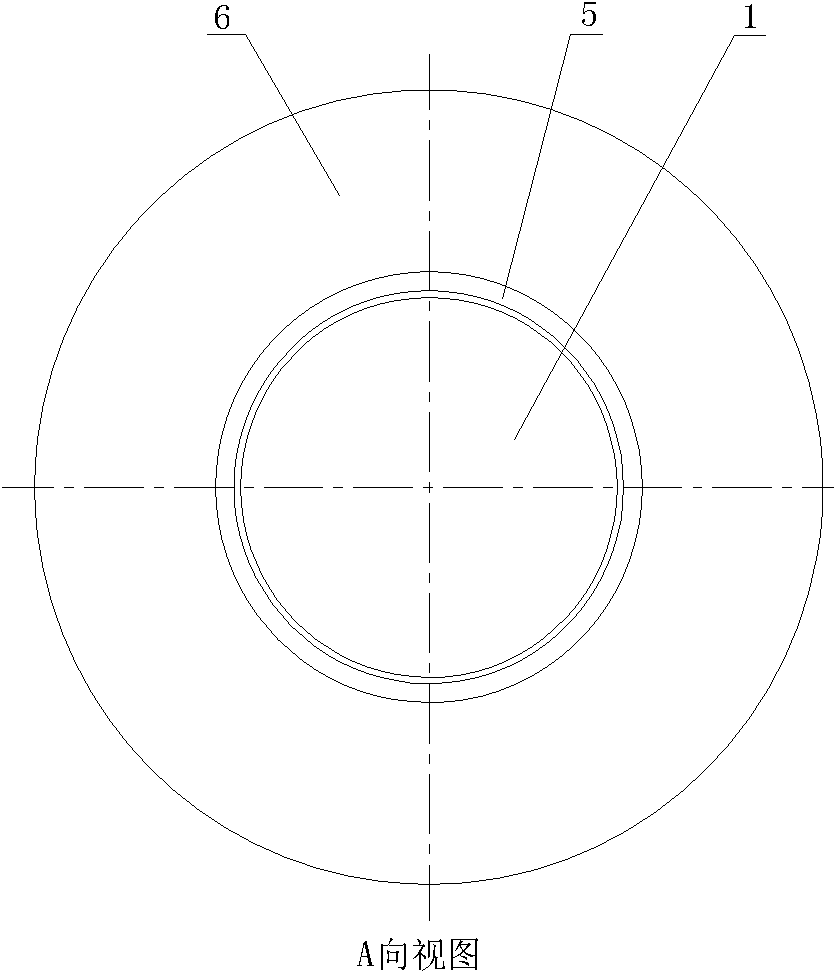

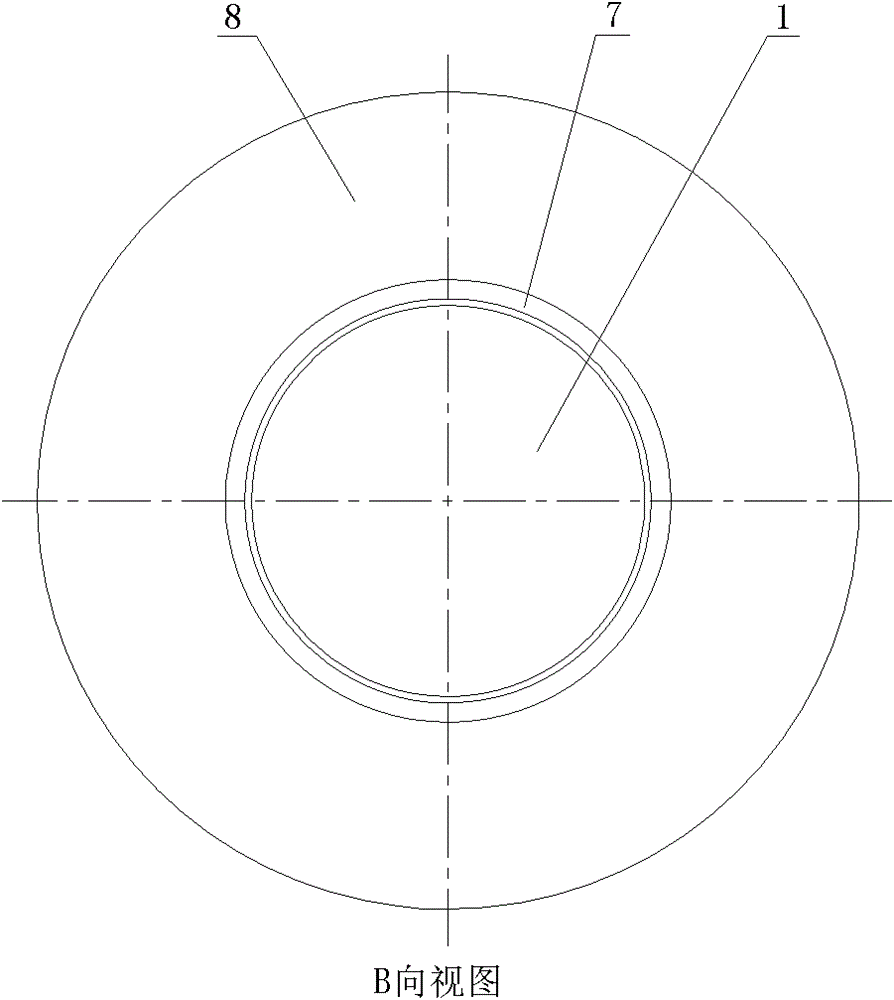

[0016] see Figure 1 to Figure 3 As shown, the arc striking device provided by the present invention is composed of two parts: a moving contact system and a static contact system. 5 and the moving side insulation cover 6, the static contact system includes the static side insulation cover 7, the static side arc ring 8, the conductive support 9 and the static arc contact 10.

[0017] The auxiliary contact 4 is fixed on the contact finger seat 3 with the screw 2, and the moving arc contact 1 moves left and right along the axial direction under the drive of the operating system to complete the opening and closing operation. The moving arc contact 1 slides on the auxiliary contact 4, and the two maintain reliable electrical contact. The moving arc contact 1, the auxiliary contact 4 and the contact finger seat 3 form a conductive channel. The moving side arc ring 5 and the moving side insulating cover 6 are fixed on the contact finger seat 3 with screws 13, and they cover the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com