Integrated secondary smoke box for converter stokehole

A technology of secondary smoke box and converter furnace, applied in the direction of manufacturing converters, etc., can solve the problems of complex installation, maintenance and replacement operation environment, scattered splicing structural parts, and many unsafe factors, so as to shorten installation time and save maintenance. cost, the effect of avoiding shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

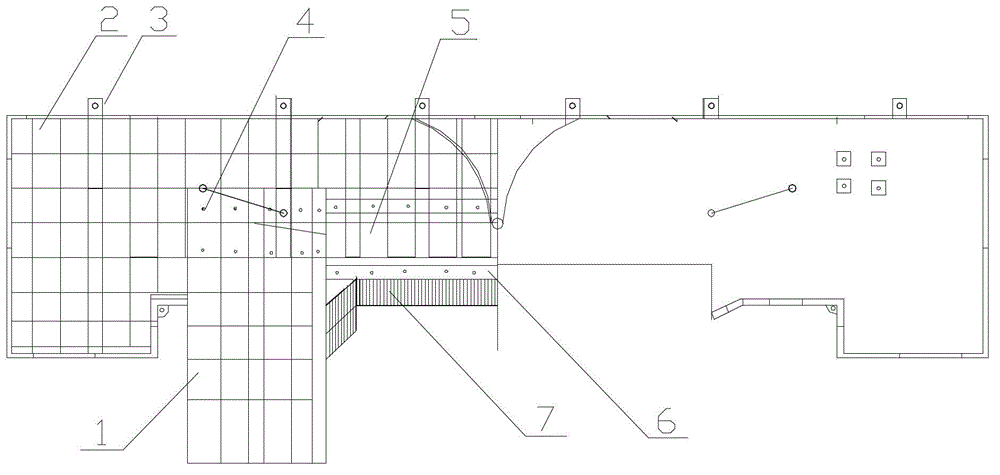

[0014] The present invention removes the smoke baffle from the secondary smoke box originally composed of the main smoke box and the smoke baffle, and changes it into an integrated secondary smoke box. The integrated secondary smoke box is mainly composed of ear plate 1, main smoke box body 2, hanging plate 3, bolt 4, baffle plate 5, hanging plate 6, hanging chain 7 and related connecting parts. Two lug plates 1 are symmetrically fixed on the inner side of the main cigarette box body 2 with bolts 4, and a baffle plate 5 is installed at the lower end of the main cigarette box body 2 between the two lug plates 1, and a hanging plate 6 is fixed at the lower end of the baffle plate 5, Hanging chain 7 is suspended below the hanging plate 6 . In order to prevent the deformation of the baffle plate 5, a stiffener plate is welded on the outside of the baffle plate 5 again. The upper part of the main smoke box body 2 is fixed with the hanging plate 3 by bolts, and the gunning cotton u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com