A kind of ito through hole capacitive touch screen and its manufacturing method

A capacitive touch screen and through-hole electrode technology, which is applied in the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve problems such as poor working stability, electrode disconnection and touch failure, interface separation, etc., to improve product reliability. performance, optimize the stacked structure, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with specific embodiments.

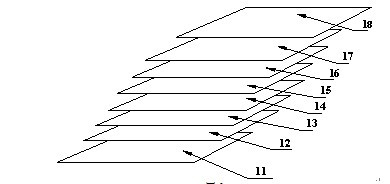

[0053] Such as figure 1 As shown, the ITO through-hole capacitive touch screen includes a chemically strengthened decorative glass substrate 11 with a thickness of 0.5 to 2.0 millimeters, and a capacitive functional substrate 13 stacked on the decorative glass substrate through an optical adhesive layer 12, with a thickness of 0.33 to 0.7 mm. mm, and the ITO electrode 14, the first insulating layer 15, the ITO through-hole electrode 16, the metal electrode 17 and the second insulating layer 18 stacked on the capacitive functional substrate in turn; the ITO electrode includes a capacitive screen drive (ITO electrode 1) The sensing electrode (ITO electrode 2) has a regular pattern structure; the ITO electrode 1 and the ITO electrode 2 are on the same level, independent of each other, insulated from each other, and designed vertically.

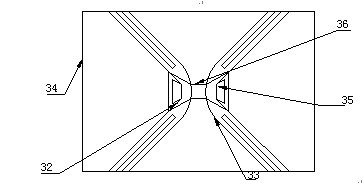

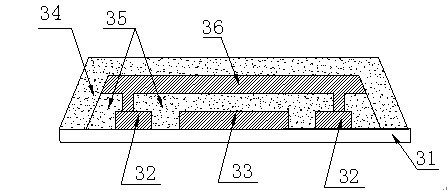

[0054] figure 2 and imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com