Method for smoke discharge, condensation and dust removal of supercharged oxygen-enriched coal-fired boiler

A coal-fired boiler and oxygen-enriched technology, which is applied in the boiler field to achieve the effects of improving economy, occupying a small space, and simple and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

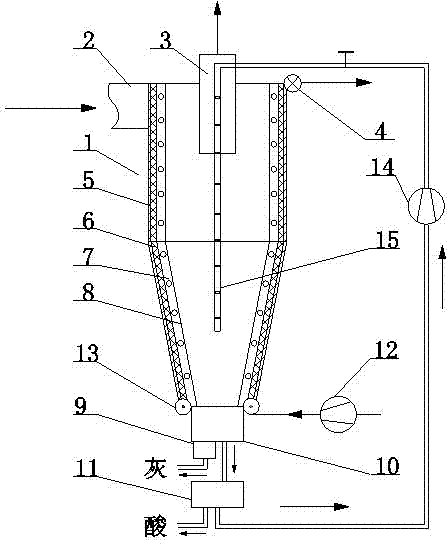

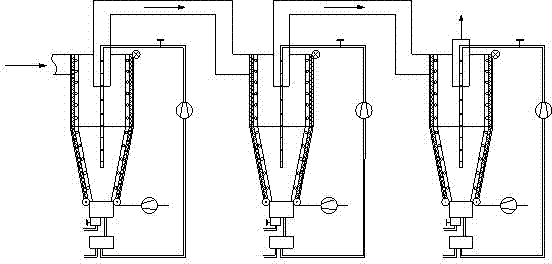

[0016] The present invention provides a supercharged oxygen-enriched coal-fired boiler exhaust gas condensation and dust removal method for a supercharged oxygen-enriched combustion power generation system. The present invention will be further described below with reference to the accompanying drawings.

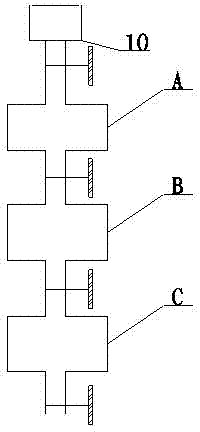

[0017] Such as figure 1 As shown, the method is implemented by a high-pressure water-cooled cyclone dust removal and condensation device 1. The upper part of the high-pressure water-cooled cyclone dust removal and condensation device is a cylindrical chamber and the lower part is a cone-shaped chamber. , The ash discharge is controlled by the ash discharge valve 9. The upper part of the device is provided with a horizontal air inlet pipe 2 and a vertical air outlet pipe 3. The working pressure of the device is 6.0-8.0Mpa, and the device is provided with a pressure layer 5, an insulation layer 6, a water wall 7 and an anti-corrosion layer 8 from outside to inside. The device al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com