Railway contact network wiring high altitude work vehicle

A technology of aerial work vehicles and aerial work buckets, which is applied in the direction of lifting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

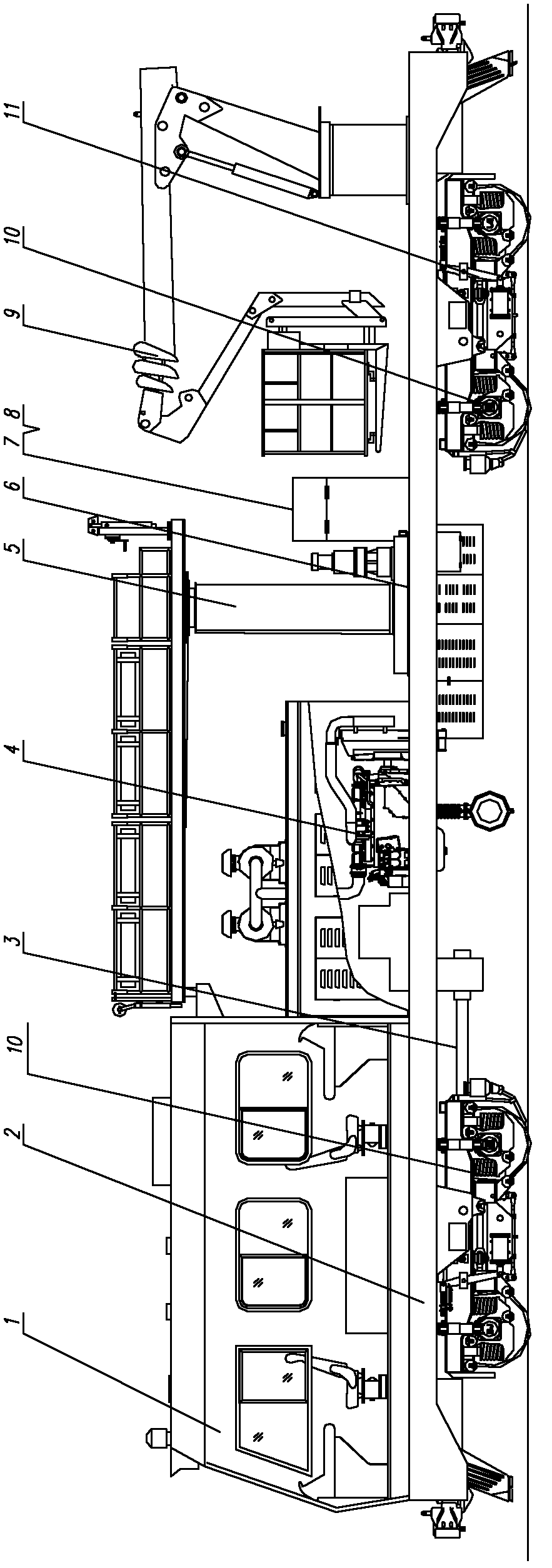

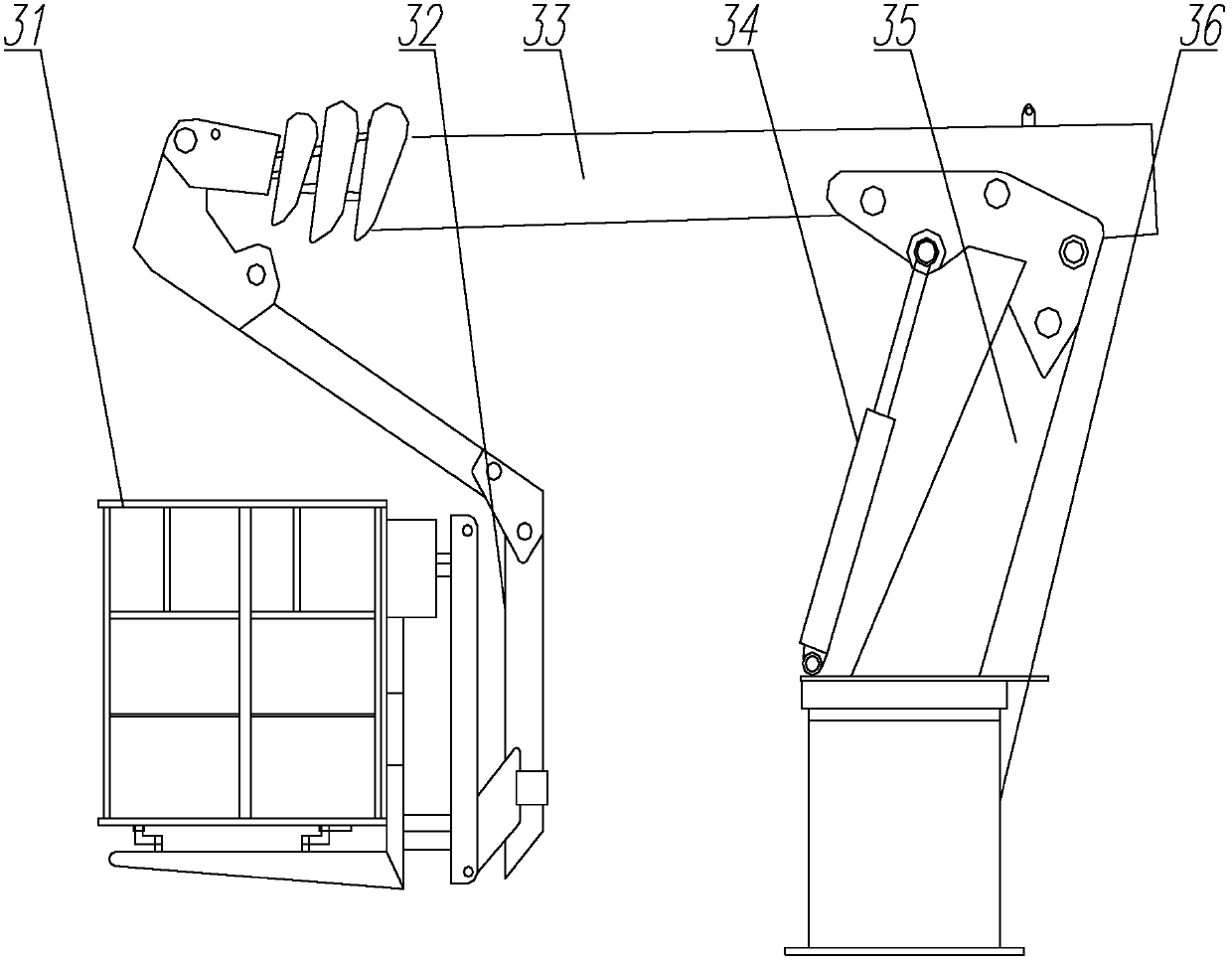

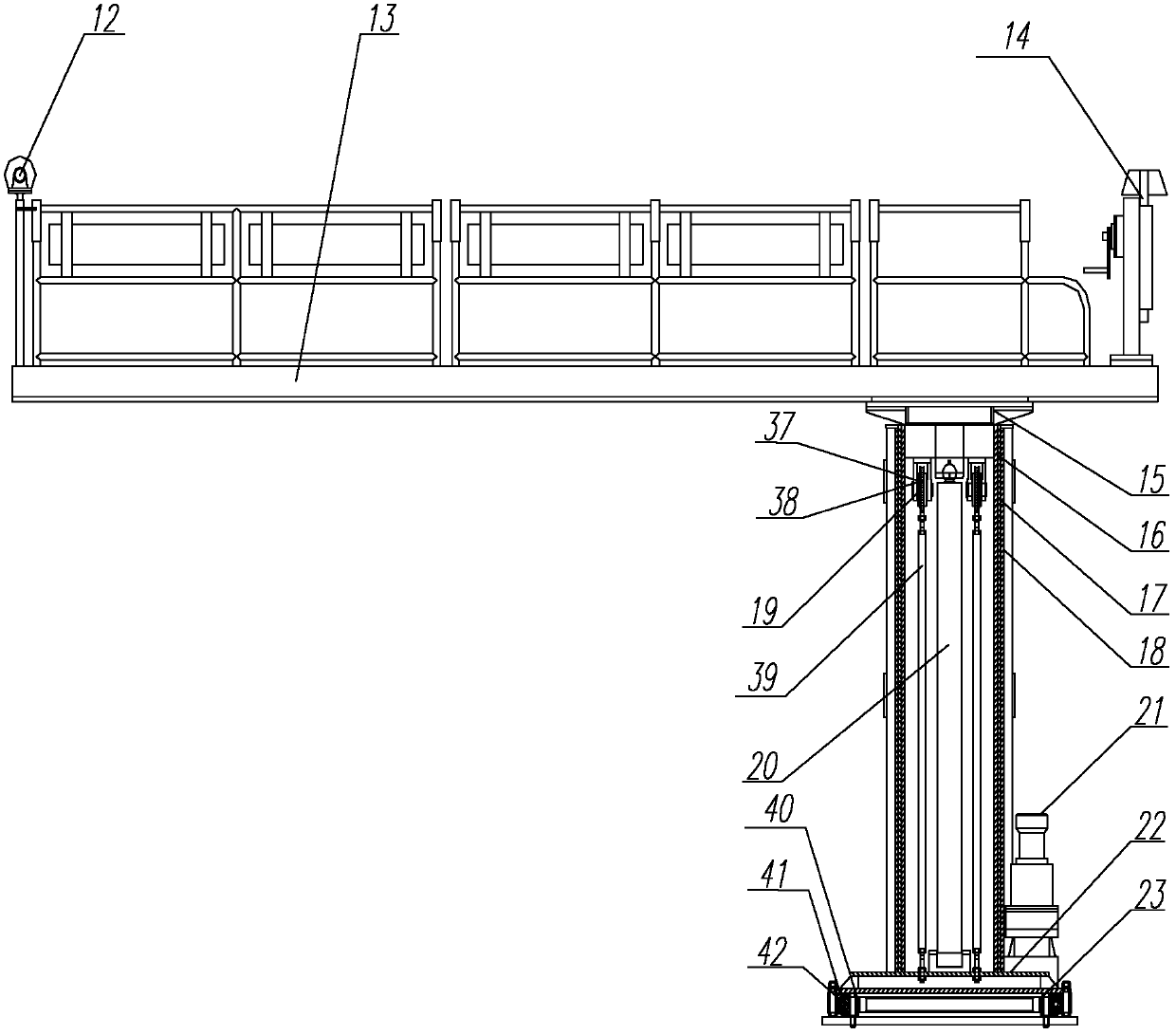

[0015] Attached below figure 1 , 2 , 3, 4 describe an embodiment of the present invention.

[0016] The railway catenary overhead work vehicle includes a car body 1, a frame 2, a transmission system 3, a power unit 4, a hydraulic control system 7, an electrical control system 8, a running mechanism 10 and a braking system 11. The car body 1 The skeleton of the car is welded by rectangular steel. The whole car body 1 is composed of two sides, the roof, and the front and rear ends respectively. After welding, it forms a frame load-bearing car body with the car frame 2, which has sufficient strength and rigidity to meet the dynamics of the whole car. performance requirements. The cold-proof and heat-insulating material filled between the inner and outer walls of the car body 1 adopts polyurethane foam, the front and rear ends of the car body 1 are electrically heated glass, and the side windows are hollow glass sash windows and screen windows are equipped with. The interior of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com