A fully automatic relay production line

A technology for producing assembly lines and relays, applied in relays, circuits, electrical components, etc., to achieve the effects of increased cost and risk, simple structure, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

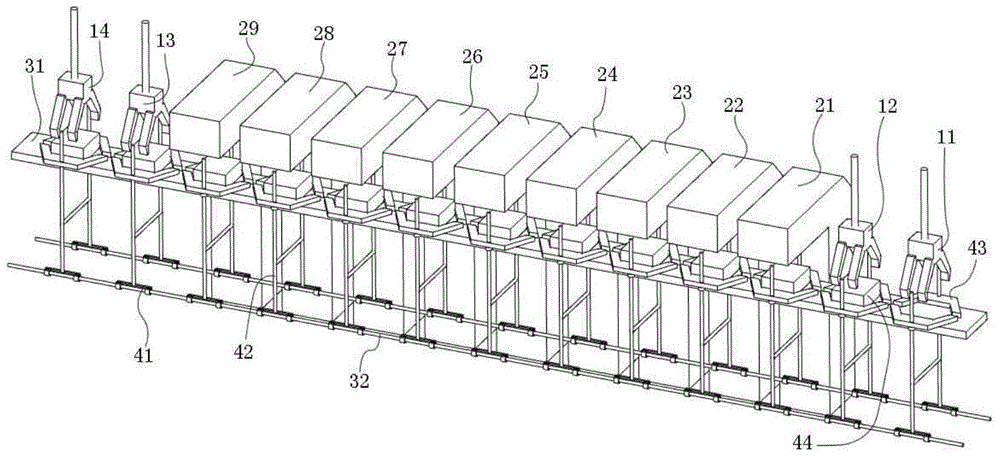

[0016] Such as figure 1 A fully automatic relay production line is shown, including the first two mechanical claws 12, the rear one mechanical claw 13, the iron core inserting machine 21, the moving spring installing machine 22, the armature installing machine 23, the front static contact installing machine 24, the moving Contact installation machine 25, rear static contact installation machine 26, terminal installation machine 27, shell installation machine 28, guide rail 32, moving mechanism 41, connecting frame 42, positioning fixture 43; the first two mechanical claws 12, iron core Plug-in machine 21, moving spring installation machine 22, armature installation machine 23, front static contact installation machine 24, moving contact installation machine 25, rear static contact installation machine 26, terminal installation mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com