foam pump

A foam pump and foam technology, which is applied in the field of foam pumps, can solve the problems of high cost and achieve the effect of preventing spring rust and uniform foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

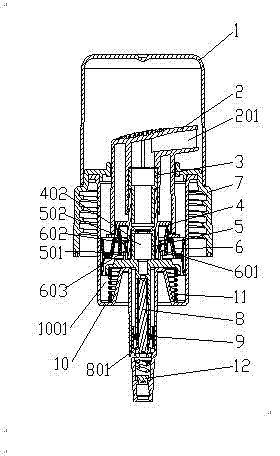

[0051] Such as figure 1 The presence of the present invention is a cord, attached image 3 Example 1 network management structure diagram, attachment Figure 5 The decomposition and attachment of the present invention Figure 4 It is shown in the structure diagram of the embodiment 1 cylinder, large piston, main column, connection rod, and small piston connection.

[0052] A foam pump is used to absorb the liquid in the container and spray the foam from the nozzle of the liquid.Large piston 6, rotation cover 7, connection rod 8, small piston 9, cylinder 10, spring and valve 12, there are network tube 3 in the head 2 and the air valve 4, the spring is set outside the main column 5, of which:

[0053]One presses 2, with a nozzle 201 bubble spray, 2 sets of heads to take over 202 lower parts 2021, with ring grooves or card slots in the inner wall of the 2021 diameter.A ring -shaped convex steps 2022 at the beginning of 2021;

[0054] One network tube 3, extend from below to push the pip...

Embodiment 2

[0073] Such as figure 2 Another working status of the present invention embodiment 2 and attachment Figure 7 Example 2 The structure diagram of the network tube, other structures are the same or similar as the embodiment 1. The foam pump is composed of the head, the car cover, and the cylinder.Large piston 6, rotation cover 7, connection rod 8, small piston 9, cylinder 10, large spring 11, valve 12 and small spring 13, with network tube at the head 2 and gas valve 4, the second spring is located in the main columnIn addition to the air room of the cylinder 10, of which:

[0074] One presses 2, with a nozzle 201 bubble spray, 2 sets of heads to take over 202 lower parts 2021, with ring grooves or card slots in the inner wall of the 2021 diameter.A ring -shaped convex steps 2022 at the beginning of 2021;

[0075] One network tube 3 ', extended from below to take over 202, the lower end of the network management 3' is a coarse filter 301 ', the upper end is a fine filter 302', and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com