Tension comprehensive optimization setting method of six-roll skin pass mill

An optimized setting and leveling technology, applied in the direction of tension/pressure control, contour control, etc., can solve problems such as product quality degradation, unit economic loss, color difference defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

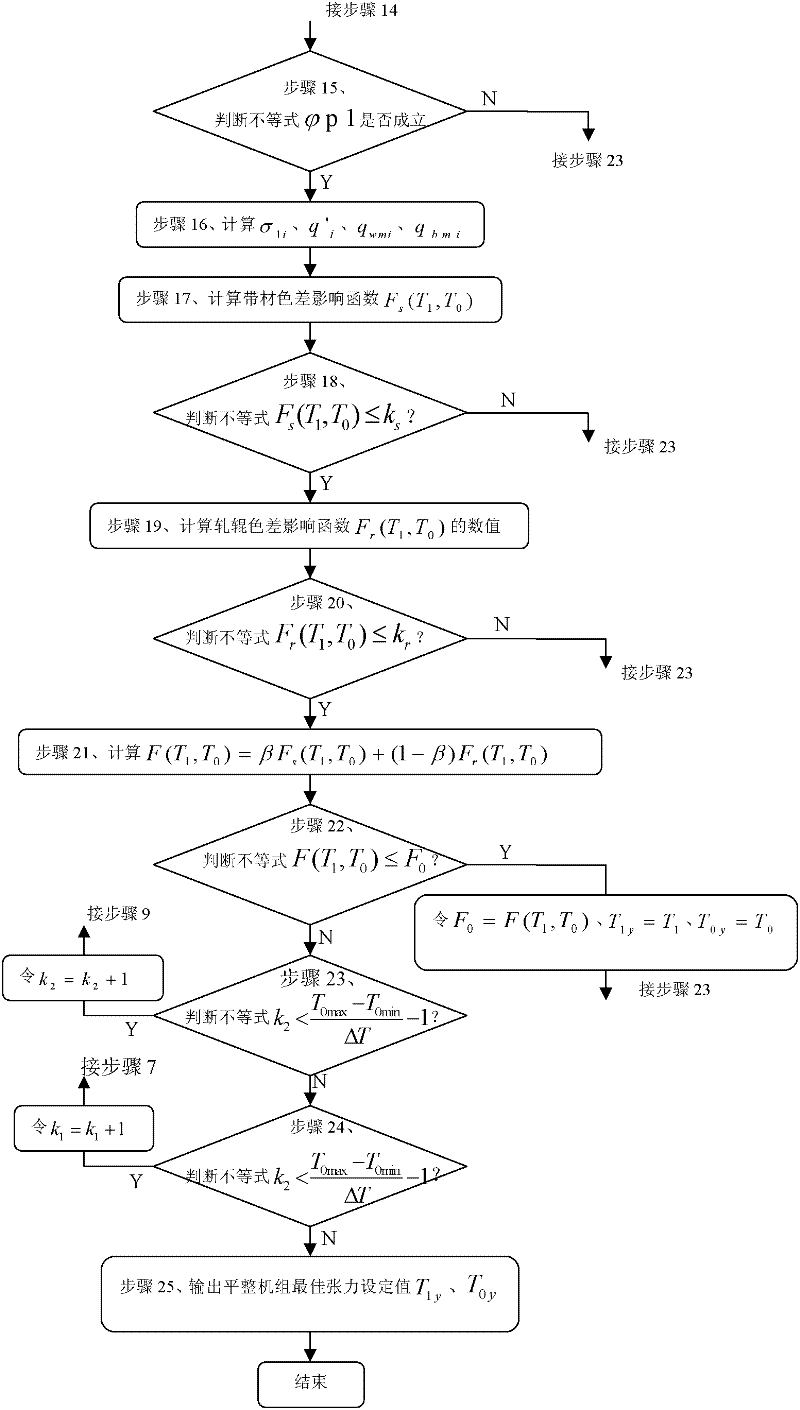

[0036] In order to illustrate the basic idea of the present invention, a certain 1850 six-roll skin pass unit is taken as an example, with the help of figure 1To describe the tension optimization setting process of the steel strip with the specification of 1200mm*0.6mm and the steel type of SPCC on a specific skin pass unit.

[0037] First, in step 1, collect the equipment and process parameters of the skin pass unit, including the work roll body length L W =1850mm, working roll diameter D W =360mm, middle roll body length L M =1850mm, intermediate roll diameter D M =400mm, back-up roll body length L b =1850mm, back-up roller diameter D b =900mm, the distance between the drive side of the back-up roller and the center of the screw on the working side is l 1 =2500mm, the center distance between the drive side of the work roll and the bending roll hydraulic cylinder on the work side l 2 =2500mm, the equivalent stiffness K of the rolling mill m = 2676000, equivalent mass...

Embodiment 2

[0065] In order to further illustrate the basic idea of the present invention, a certain 1850 six-roll skin pass unit is taken as an example, with the help of figure 1 To describe the tension optimization setting process of the steel strip with the specification of 1600mm*1.0mm and the steel type of DC06 on a specific skin pass unit.

[0066] First, in step 1, collect the equipment and process parameters of the skin pass unit, including the work roll body length L W =1850mm, working roll diameter D W =360mm, middle roll body length L M =1850mm, intermediate roll diameter D M =420mm, back-up roll body length L b =1850mm, back-up roller diameter D b =900mm, the distance between the drive side of the back-up roller and the center of the screw on the working side is l 1 =2500mm, the center distance between the drive side of the work roll and the bending roll hydraulic cylinder on the work side l 2 =2500mm, the equivalent stiffness K of the rolling mill m = 2676000, equiva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com