Forming roll for kitchen knives and using method

A technology for rolls and kitchen utensils, which is applied in the field of material forming rolls, and can solve problems such as not being able to meet the requirements of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

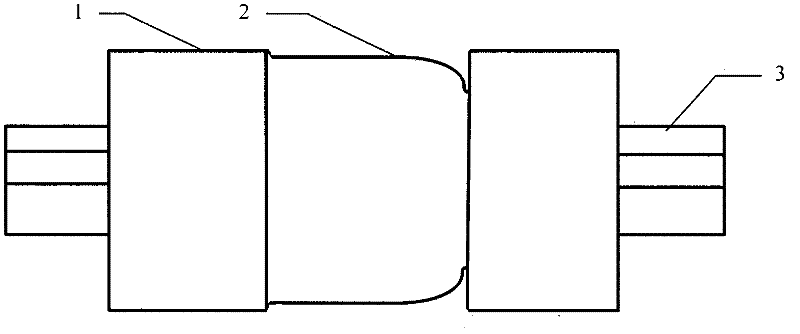

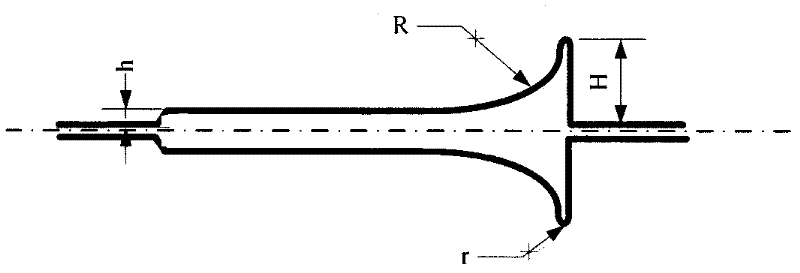

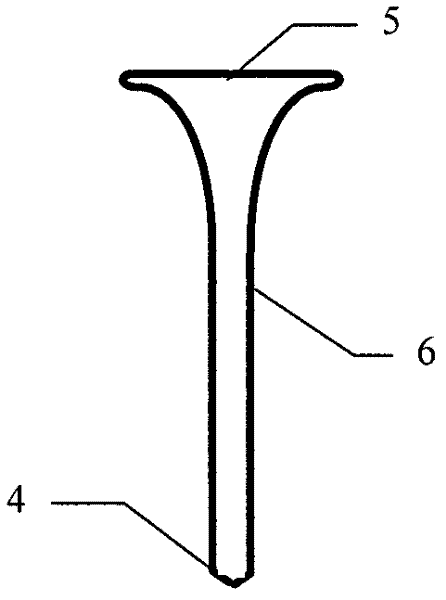

[0014] see Figure 1~3 , a forming roll for kitchen knives and its use method, which is composed of a roll body 1 and a roll connecting shaft 3, and is characterized in that: the roll body 1 is circumferentially distributed with a special-shaped pass 2 with a V-shaped deep groove; One side of the V-shaped deep groove of special-shaped pass 2 is vertically perpendicular to the roller surface, and the other side gradually transitions into a horizontal shallow groove through the arc surface. The depth of the V-shaped deep groove of special-shaped pass 2 is H=510mm, and the bottom corner of the V-shaped deep groove has a circular arc transition, and the radius of the transition arc is r=2-5mm; the depth of the shallow groove is h=0.5-2mm. The transition arc radius R of the deep groove and the shallow groove of special-shaped pass type 2 is 30-40mm.

[001...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com