An assembly and adjustment device for projection objective lens of lithography machine

A technology of projection objective lens and lithography machine, which is applied in the direction of exposure device of photoplate making process, exposure equipment of microlithography, etc., can solve the problems of difficult to achieve high-precision assembly, real-time detection and automatic adjustment, and meet the requirements of high-precision assembly tolerance , Improve the efficiency of assembly and adjustment, and the effect of good real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

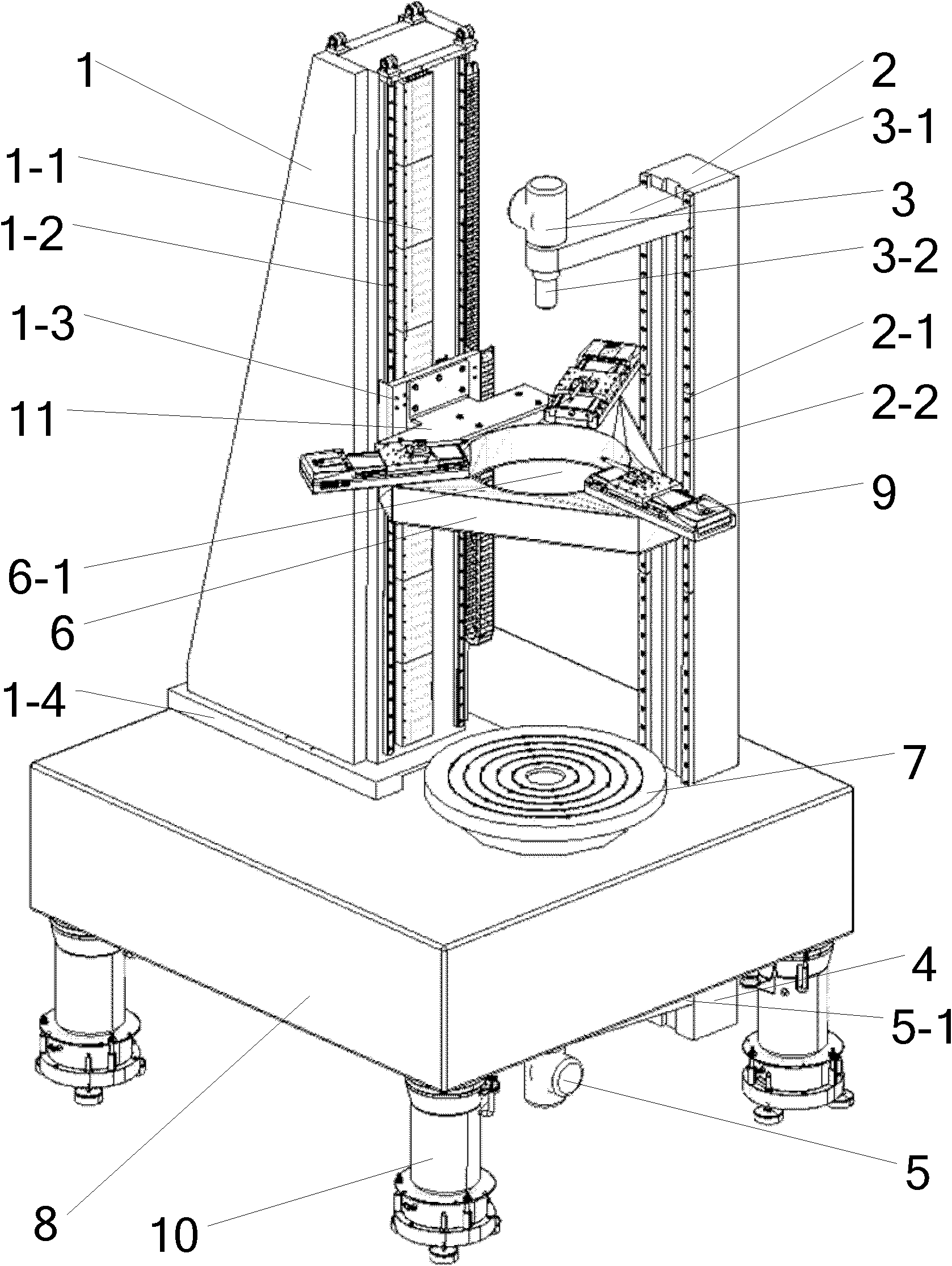

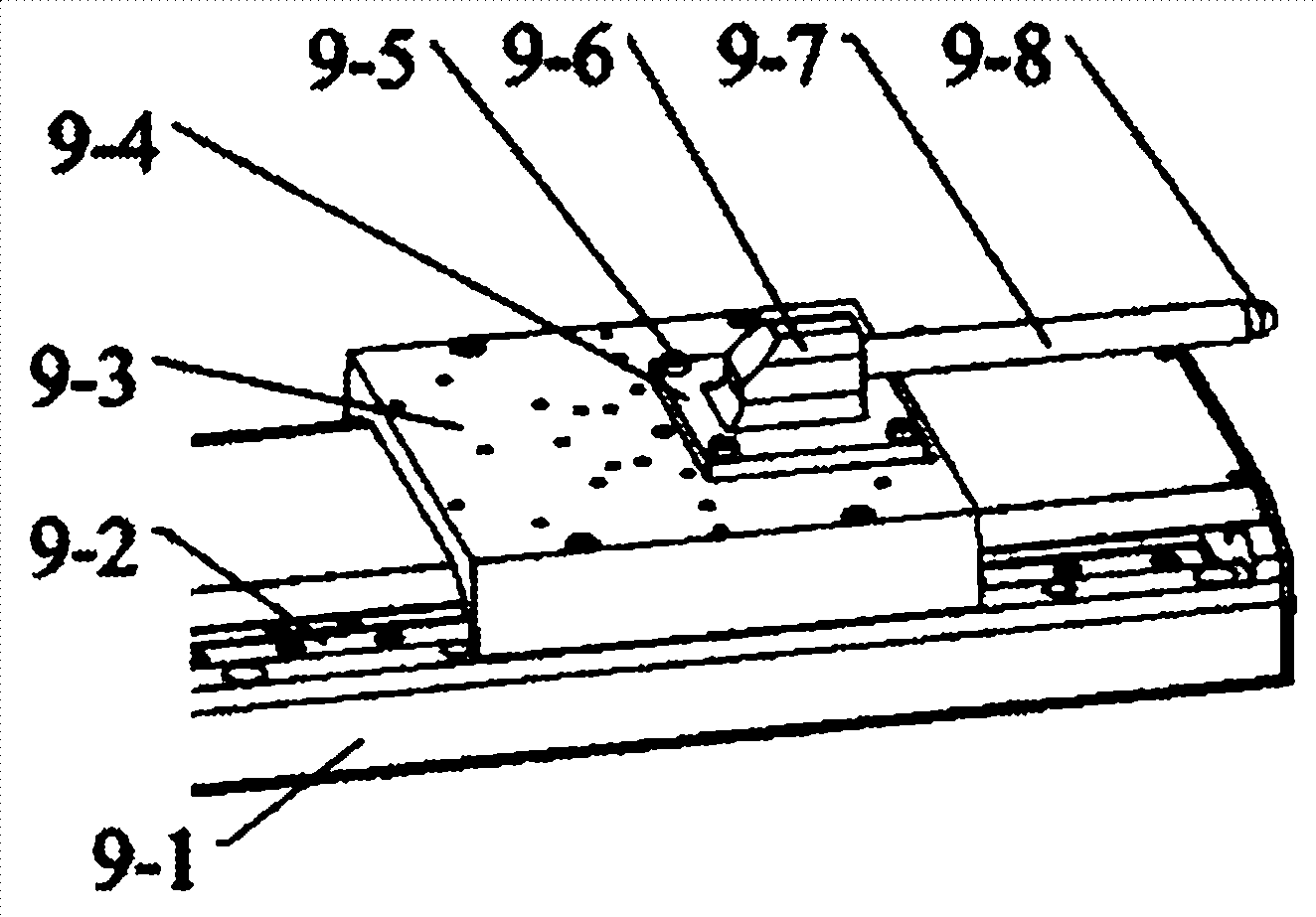

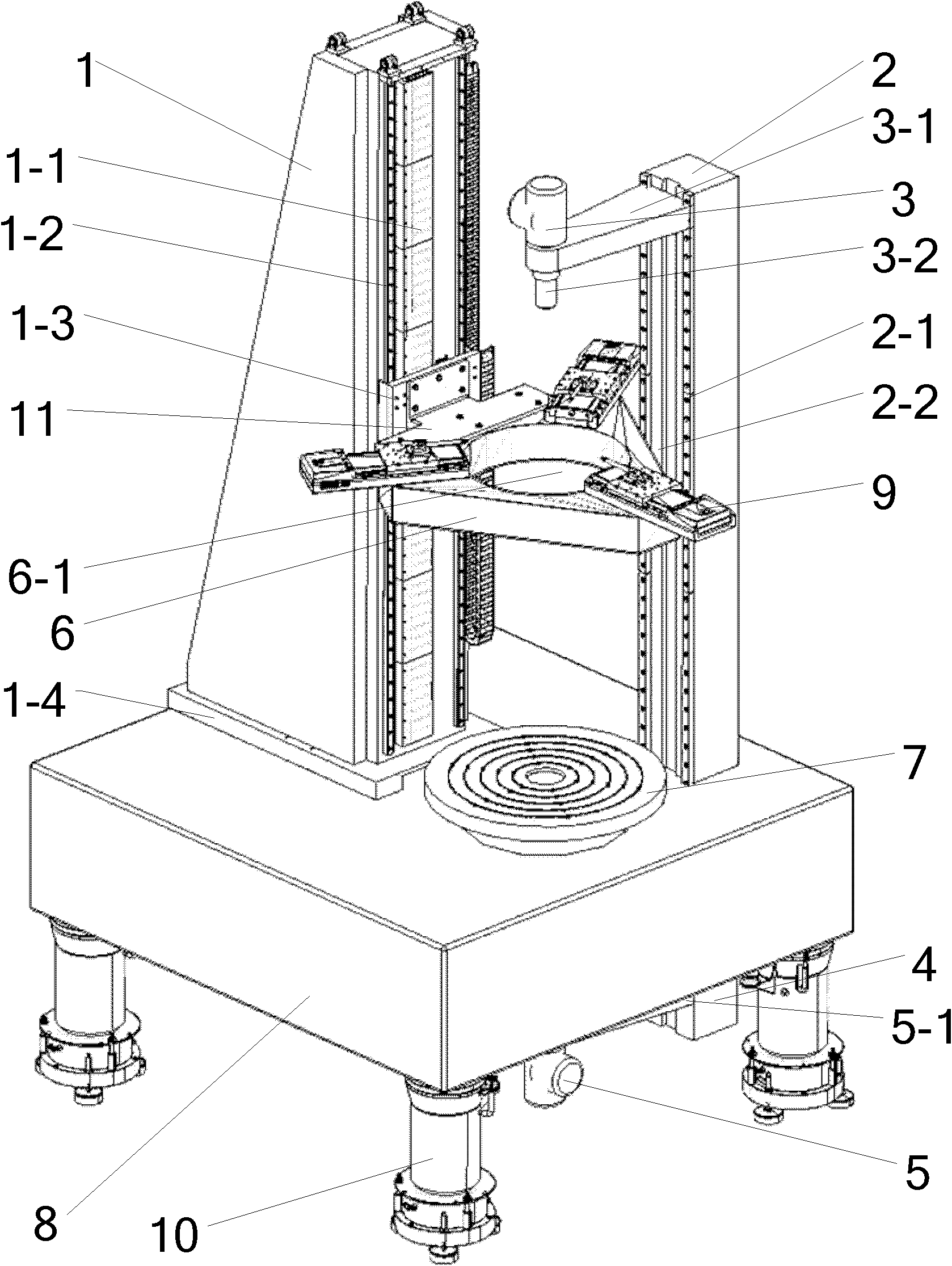

[0015] Specific implementation mode 1. Combination figure 1 and figure 2 Describe this embodiment, an installation and adjustment device for projection objective lens of a lithography machine, the device includes a Z-axis column 1, an upper detection column 2, an upper detection head 3, a movable adjustment platform 6, an air bearing turntable 7, and a horizontal marble platform 8. The adjustment mechanism 9, the vibration isolation support leg 10 and the adjustment platform connecting bracket 11; the Z-axis column 1, the upper detection column 2 and the air flotation turntable 7 are respectively vertically fixed on the horizontal marble platform 8; the upper detection head 3 passes through The upper detection head frame 3-1 is fixed on the upper detection column 2, the adjustment mechanism 9 is fixed on the upper surface of the movable adjustment platform 6, and the movable adjustment platform 6 is fixed on the Z-axis column 1 through the adjustment platform connection brack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com