Water-oil mixed combustion rotating engine

A rotary engine and co-combustion technology, which is applied to combustion engines, engine components, machines/engines, etc., can solve the problems of volume change, large energy loss, and limited power, so as to increase output power, increase output power, and reduce energy loss. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

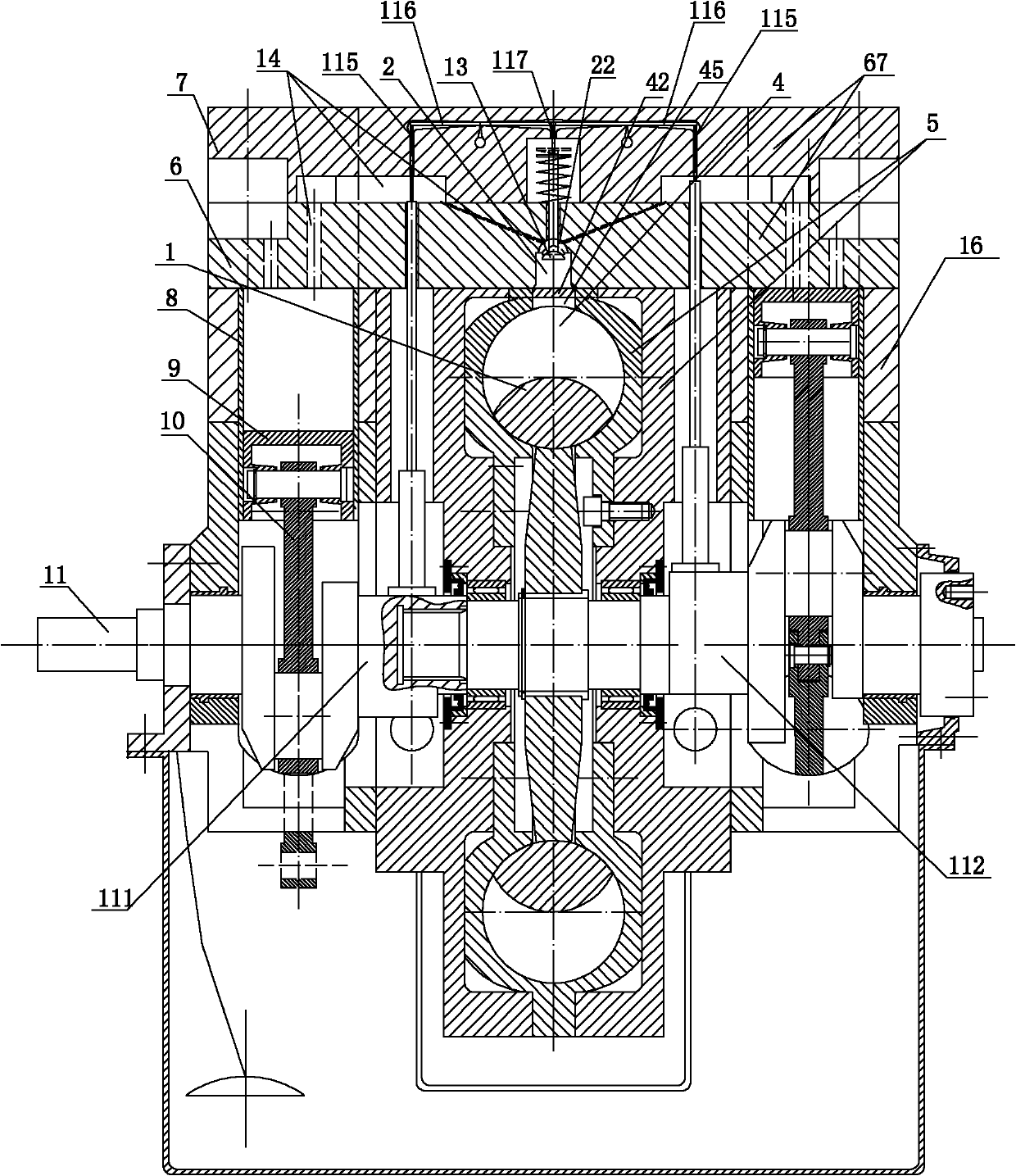

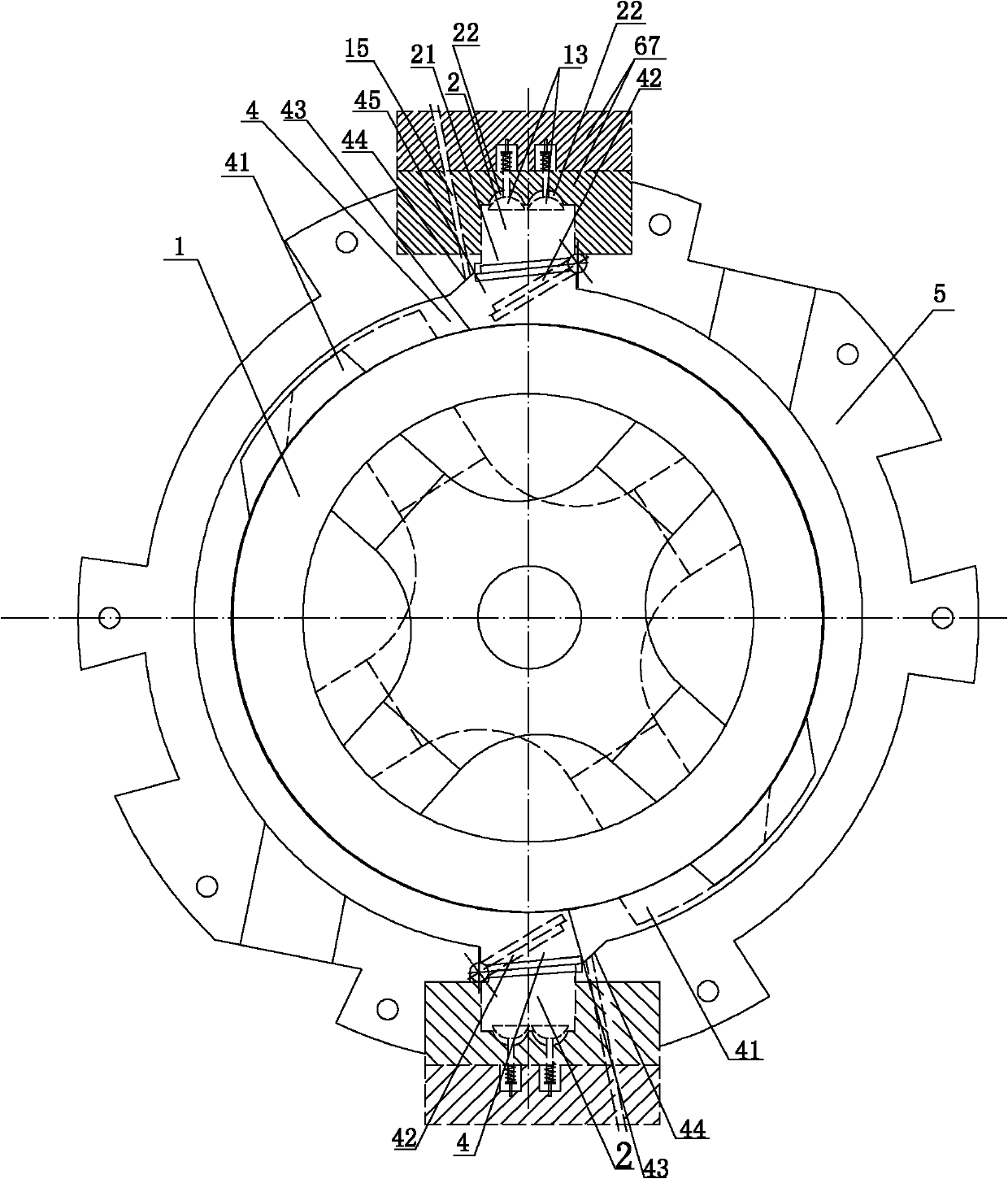

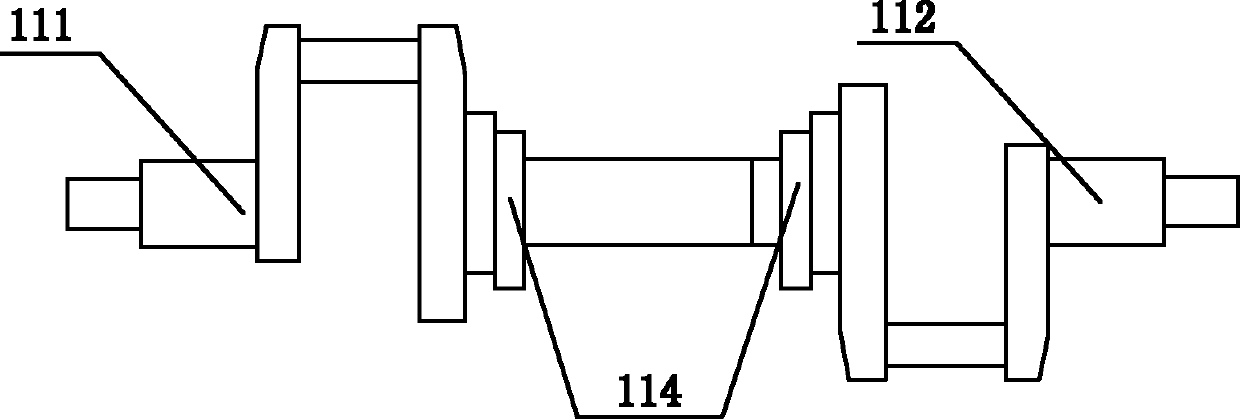

[0017]For the convenience of understanding and description, the working principle of the water-oil mixed-fired rotary engine of the present invention is firstly introduced: the water-oil mixed-fired rotary engine of the present invention first compresses the gas into high-pressure gas by the gas compression device , and then delivered to the combustion chamber 2 located on the cylinder head body 67 to mix with the fuel delivered to the combustion chamber 2, then ignited by the ignition plug, combusted and exploded, the compressed gas expands and breaks open the movable closing door 42, and enters the expansion chamber 4 Drive the rotary piston disc 1 to rotate, and then drive the transmission shaft 11 to rotate, so as to achieve the purpose of converting chemical energy into machinery. Taking a working cycle as an example, the gas compression device on the left first compresses the gas and supplies it to the combustion chamber 2, and the corresponding gas compression device on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com