Device and construction method for overall lifting of single-story industrial factory roof

An industrial factory building, the overall jacking technology, applied in the direction of building maintenance, construction, building construction, etc., can solve the problems of destructive structural columns, high construction costs, waste of resources, etc., to shorten the construction period and reduce the cost of construction measures , The effect of saving equipment usage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

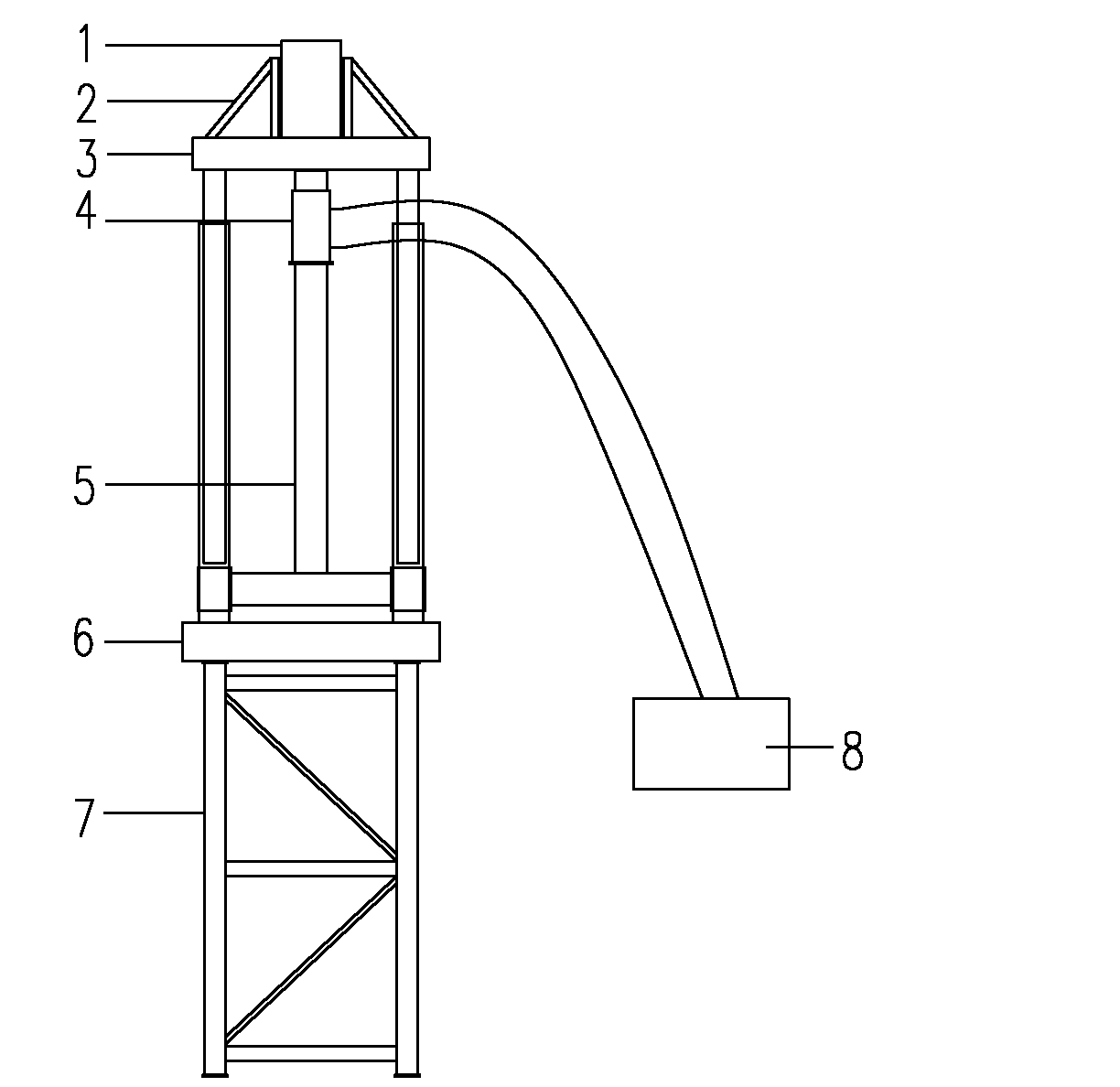

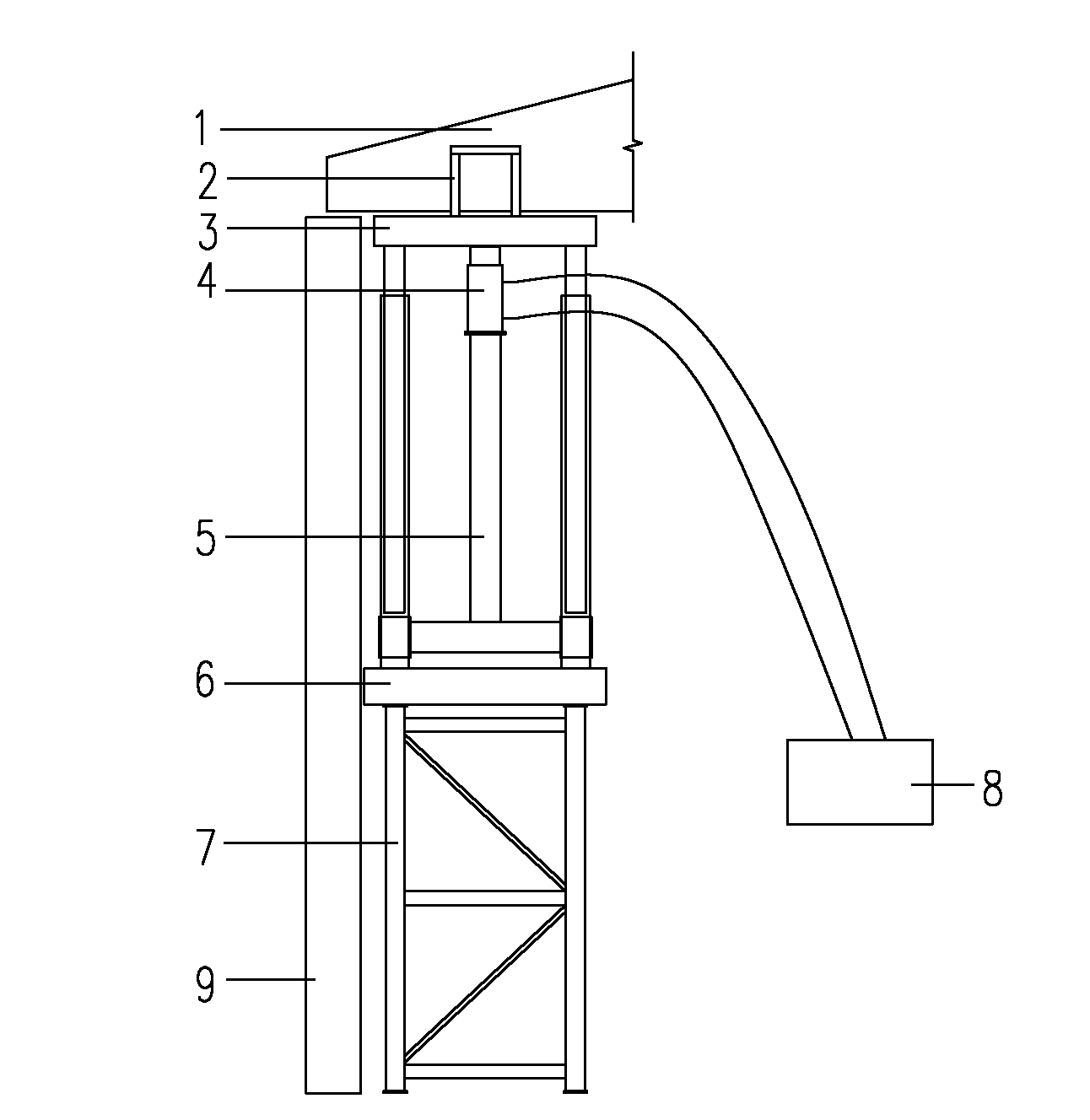

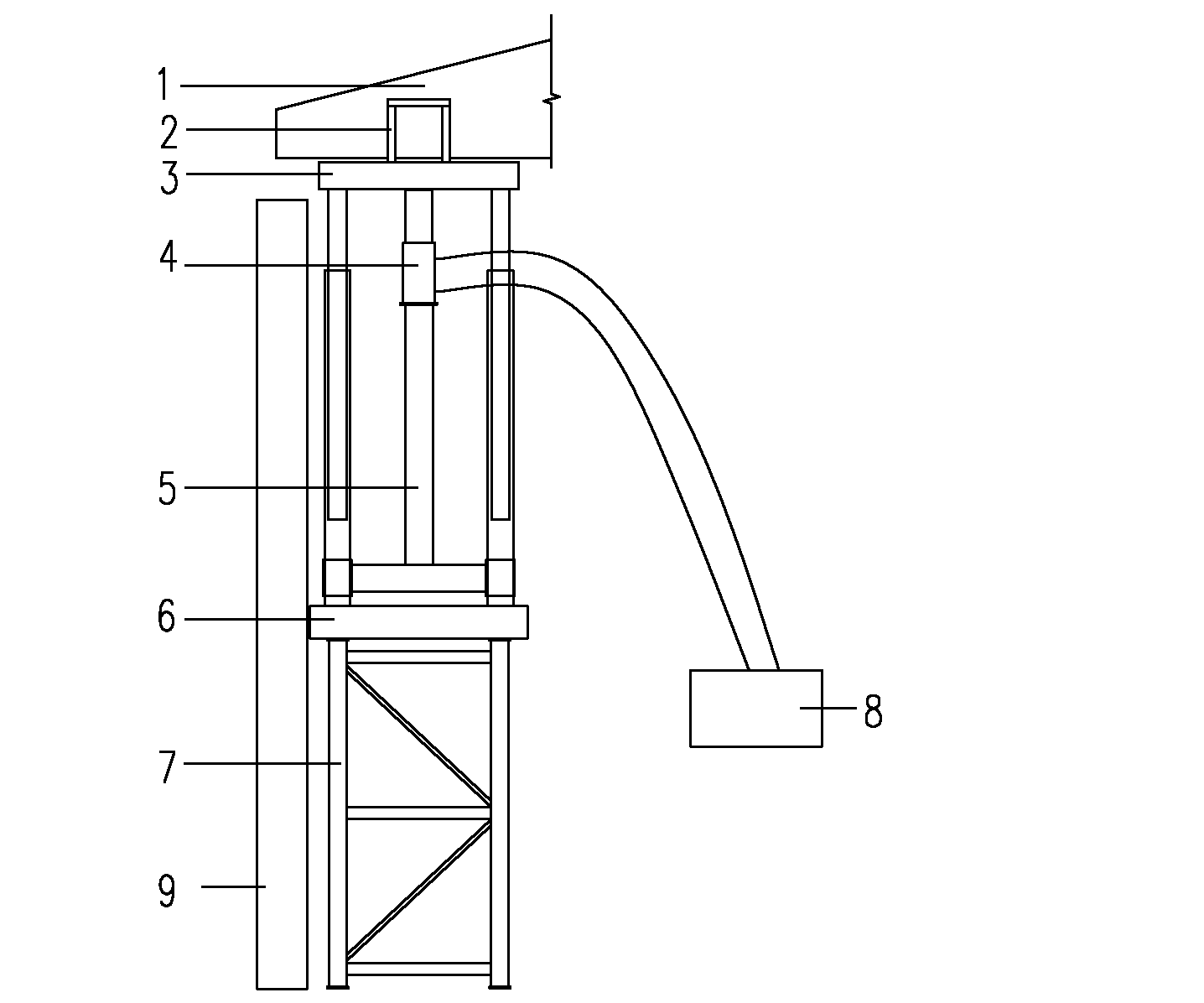

[0027] Figure 1a It is a schematic diagram of the front elevation of the jacking system assembly of the present invention, Figure 1b It is a schematic diagram of the side elevation of the jacking system assembly of the present invention, Figure 2a It is a schematic diagram of the working principle of the jacking system jacking up the roof of the present invention, Figure 2b It is a schematic diagram of the jack oil return working principle of the jacking system of the present invention, image 3 It is a perspective view of the jacking device of the present invention.

[0028] As shown in Figures 1 to 3, a single-story industrial factory roof integral jacking device is composed of three parts: a jacking device, a vertical force transmission device 7 and a synchronous control system. The jacking device is the power to lift the roof as a whole. The system is located at the bottom of the original roof truss beam 1, supported on the top of the vertical force transmission dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com